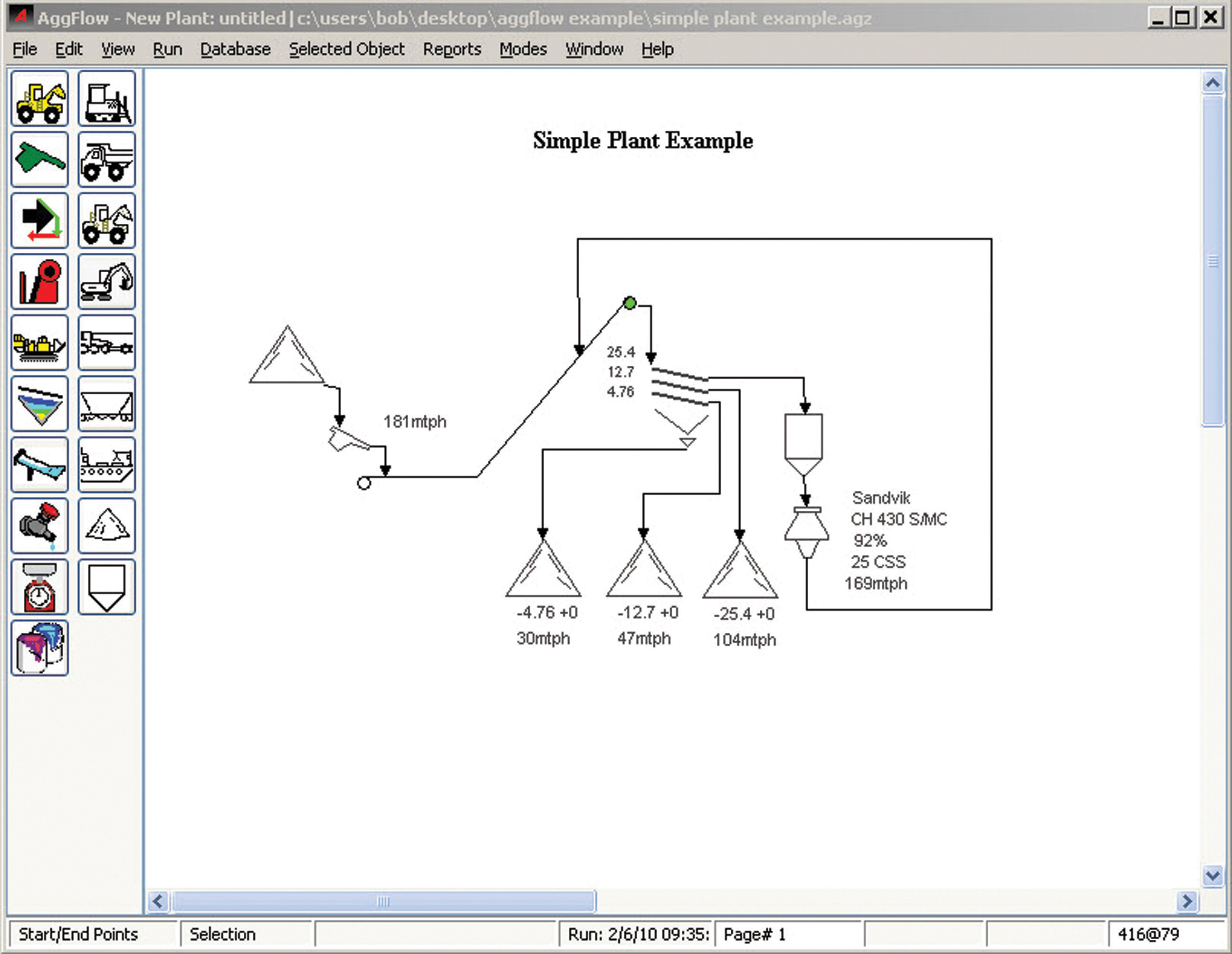

BedRock Software's AggFlowSite is described by the company as the next evolution in plant simulation and optimisation for the global aggregate industry.

AggFlowSite delivers the full functionality of the company's traditional

"AggFlowSite is perfect for individual plant simulations, small producers, consultants, dealers or equipment manufacturers working on a single project or any plant analysis where multiple remote people need to access the project. It will enhance and expand the way industry professionals communicate set-ups, share ideas and develop solutions," said Bryan Lewis, president of BedRock and inventor of the AggFlow program.

The site administrator (purchaser) designates and manages who can access the site (internet access is required to operate AggFlowSite) while the AggFlow program is designed for one user simulating multiple plants and does not require internet connectivity to operate.

Both simulations are said to help improve profitability by identifying inefficiencies and bottlenecks; by accurately assessing the impact of proposed changes or new equipment before they are made, and by reducing plant down-time and production errors. The program also helps track and reduce emissions and fuel consumption by refining overall plant efficiency, and users can calculate mass aggregate and water balances flowing through a plant simulation using stationary and mobile equipment, thus optimising and maximising production of the desired products. They can also select from the pre-populated equipment data library or install their own equipment models in the program using the generic equipment application.

Currently, the program provides calculations for more than 3,000 models of aggregate crushing, screening and washing equipment.