Concept-X was unveiled in 2019 as the world's first automated construction solution. At a demonstration of Concept-X in Korea, attendees witnessed autonomous construction equipment performing everyday jobsite tasks. The latest Concept-X 2.0 version being demonstrated at Intermat includes the following updates:

·New dozer added to autonomous equipment line-up

·Autonomous driving and blade control based on the Global Navigation Satellite System (GNSS)

·Automated 3D grading with tiltrotator accessory

·Enhanced machine-learning-based auto-digging and loading

·Integrated work planning algorithm applied

·Advanced E-Stop safety technology

The Concept-X 2.0 autonomous construction equipment involved in this latest iteration includes the DD100-CX dozer and DX225-CX crawler excavator. Both machines feature a new cabinless design and a linear core design language. A live demonstration of this autonomous construction equipment is taking place several times a day on the Develon stand.

Concept-X Integrates ICT and AI

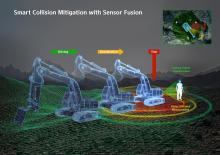

Concept-X integrates technologies related to ICT and AI to revolutionise the construction machinery industry and create sustainable customer value. Concept-X includes automated construction site solutions, surveying tasks using drones, unmanned automation of equipment, and remote control based on 5G communication to increase productivity and reduce costs and risks based on accurate, fast work at the construction site.

The core of Concept-X is X-Center, which is a control system that enables the user to view equipment at the construction site and worksite at a glance. It surveys the terrain of the worksite through scanning using drones, and the data collected from various sites are analysed to instruct unmanned equipment and manage the equipment in an integrated manner.

Develon also implements autonomous solutions, equipment with an unmanned, automated solution that can perform work accurately and quickly based on analysed data from X-Center. Prognostics and Health Management (PHM) is implemented to allow future equipment to diagnose its own condition and alert users of possible failure in advance. PHM manages risk factors in advance by forecasting the remaining life through the checking of the status change history of each part as well as the overall status at the time.

Develon aims to contribute to customer convenience with differentiated competitiveness by implementing the worksite business model with maximised efficiency and productivity through Concept-X, a solution optimised for the future construction site.

Concept-X Versions 1.0 and 2.0

Concept-X 1.0 is a project that combines cutting-edge technology with a focus on human connection to create power that improves all lives. The excavator in this project is unique because it does not have a cabin and is designed to re-imagine the relationship between humans and machines through AI technology. Concept-X 2.0 is the successor to Concept-X 1.0 and takes autonomous smart constructions to the next level. This technology provides outstanding work efficiency with a new 3D MC algorithm, resulting in an impressive 13% improvement, allowing for more detailed and complex operations.

The Concept-X 2.0 Dozer has advanced safety technology with its 180-degree detection range, interlocked machine control, and LED integrated into machine operations, providing a nonverbal language to understand the equipment's status safely. The relationship between humans and machines will continue to strengthen as technology advances, and Develon's Concept-X 3.0 technology will bring improved and optimised workflows and effective interactions between people. The opportunities lie ahead, and Concept-X 2.0 is designed to take us there.