Developing technologies and software solutions are making quarrying operations leaner and safer, and companies are bringing value-adding services to their digitalised solutions for blasting operations in the sand and gravel sector. Liam McLoughlin reports.

EPC-UK successfully launched its subsidiary company, EPC Metrics, last year, and with it, a team of experienced engineering specialists capable of offering technical support and services to improve blasting, site mapping and monitoring within quarrying operations.

Ryan Ward, commercial manager at the UK-based commercial explosives and drilling & blasting services provider, says that the technical and consultancy services provided by EPC Metrics are increasing the quality of data available to make informed decisions within the quarrying industry.

"This enables us to support and improve a cross-section of quarrying disciplines utilising state-of-the-art drone-mapping services to help sand and gravel production become increasingly efficient," Ward adds. "EPC Metrics' additional specialisms of noise monitoring, vibration-monitoring equipment provision, hire and calibration, and engineering consultancy can also realise a series of problem-solving solutions related to the sand and gravel field."

By drone mapping a site and processing gathered data for examination within an interactive software platform, sand and gravel operations can have digitalised access to information detailing their haul-road gradients, bund-height calculations, stockpile surveys, volumetric analysis, and project tracking.

The data can also be used to conduct safety telematics, ensure compliance, study interactive 3D models, utilise distance and height-measurement tools, and support quarry development planning.

"There are currently 36 Civil Aviation Authority (CAA) qualified drone pilots within the EPC-Metrics team," Ryan continues, "with the skills to operate drones nationwide, including a WingtraOne Professional vertical take-off and landing (VTOL) fixed-wing drone from within a modern fleet. The drones are used to safely capture data from any area of a quarry, which is then used, in conjunction with photogrammetric techniques, to create highly accurate, fully geo-referenced 3D models, from face profiles to full quarry maps, which can be regularly recreated as a quarry environment changes.

"The technology we're bringing to the field is also enabling EPC Metrics to perform fully remote, environmental monitoring on site," Ward says. "Through our partnerships with leading system manufacturers we can measure noise, vibration, air over-pressure and environmental conditions. As most drilling and blasting operations must adhere to strict, site-specific planning regulations, including noise restrictions, we're working to make sure that activities, including those relevant to sand and gravel processes, remain compliant. We use and can hire permanent fixed monitoring stations to gather event data and real-time results in the field. These results can then be fed back to an online platform, reviewed and analysed, then easily communicated to relevant parties."

Using its drone technology, EPC Metrics has supported digitalised quarrying processes at several quarries across the UK, recording and analysing the data gathered and safely optimising aspects of mineral-extraction performance.

By combining advanced photogrammetry techniques and browser-based 3D surveys, EPC Metrics has helped prioritise the quarries' operational safety and enhanced site efficiencies, development, and mineral-extraction planning. By improving data accuracy using highly detailed imagery from a 42-megapixel camera, advanced data analysis from volumetric cut and fill measurements has been made possible. This has enabled EPC Metrics to progress in its work in safety analytics, face height, and distance measuring. Furthermore, EPC Metrics' surveying practice has been more accurate, cost-effective, and reliable as the information can be geo-referenced using GPS.

Automated drill and blast design can significantly improve the efficiency, safety, and cost-effectiveness of quarry operations, according to US-based Maptek, which provides software, hardware and services for the mining and quarrying industries.

Maptek BlastMCF is a software solution offering comprehensive blast design and analysis, which can guarantee improved productivity and safety. The company says this is particularly relevant given that engineering-intensive methods are impractical for lean operations.

Safety is a paramount concern in the quarry industry. Automated drill and blast-design tools allow better control over blast patterns and sequencing, reducing the risk of accidents and hazardous situations for quarry personnel.

With the BlastMCF automation approach, Maptek says operators can easily generate scenarios that help them understand the interrelated factors that influence blast performance.

Quarry operations must often adhere to environmental regulations and minimise their impact on the surrounding ecosystem. Automated blast-design software can help optimise blast patterns to reduce vibration, dust, and noise, thus aiding compliance with environmental standards.

Efficient blast designs can improve the overall productivity and throughput of a quarry. By automating the design process and optimising blast parameters, quarries can increase production rates and meet market demands more effectively.

They also lead to significant cost savings in reducing drilling, blasting and material-handling expenses. By automating the design process, quarry operators can identify the most cost-effective blasting strategies and minimise resource wastage.

BlastMCF can generate precise and accurate blast designs based on geological data, quarry layout and other critical parameters. This reduces the chances of over-blasting or under-blasting, which lead to wastage of resources and increased operational costs.

Controlling the fragmentation size of the blasted material is crucial for quarry operations. Automated design software can optimise blast patterns to achieve the desired fragmentation, which in turn improves downstream processing, reduces wear and tear on equipment, and enhances the quality of the final product.

Maptek's BlastMCF allows for integrating various data sources, such as geospatial data, drilling data and geological models. This integration helps quarry operators make informed decisions and adapt to changing conditions in real-time.

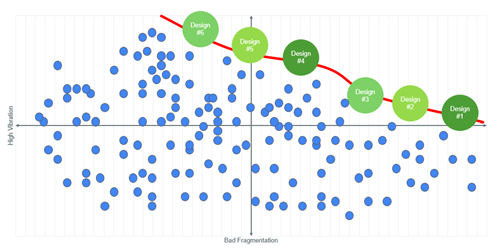

A generic algorithm enables faster, easier scenario analysis to objectively validate and verify design concepts quickly. This allows operations to benchmark the critical factors that impact blast performance specific to their site conditions.

A significant advantage of BlastMCF is the automated generation of drill patterns, per-hole charge plan and timing in a single step. Detailed reporting and analysis capabilities allow quarry managers to track performance, make data-driven decisions, and continuously refine blast designs for ongoing improvements.

Mark Roberts, global product strategy manager at Maptek, says that BlastMCF automated drill and blast-design tools play a crucial role by enhancing safety, precision, cost-effectiveness, and environmental compliance. Combining online subscription licensing, machine learning, and cloud processing can save thousands of dollars per blast to help quarry operators optimise their blasting operations, improving overall efficiency and profitability.

Australia-based multinational Orica has released a new integrated digital solution for the quarry market to streamline and optimise blasting operations.

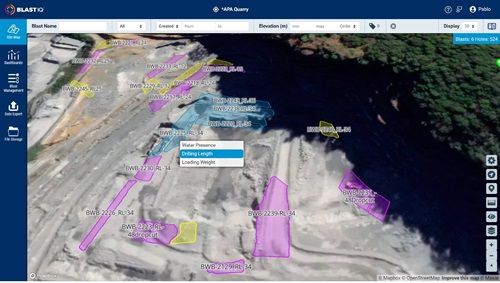

BlastIQ Quarry is a smart solution that harnesses the power of digital technologies to help quarry operators optimise their drill and blast activities in near real-time. Developed by Orica Digital Solutions, BlastIQ Quarry allows quarry operators to design blasts according to performance objectives and presents drill and blast insights for continuous blast optimisation.

Developed with customer feedback and deep blasting experience in quarry operations, the smart digital blast-optimisation platform provides a single source of truth and delivers instant pre- and post-blast insights. Operators can collate their data digitally instead of manually handling paper-based information and derive insights to inform their drill and blast performance.

Head of blast design and execution for digital solutions at Orica, Cu Luu, details the key benefits of the new blast-control solution, saying: "Overall, BlastIQ Quarry is a powerful and comprehensive solution that can help quarries improve the efficiency of their drill and blast operations, reduce overall cost, ensure data accuracy, drive productivity, and maintain regulatory compliance. Its integrated and connected components provide a complete solution that delivers real results and drives continuous improvement for the industry."

Complementary applications to enable a synergistic workflow include the SHOTPlus blast-design and modelling software; BlastIQ Mobile Lite, which places blast designs and hole conditions in the palm of operators' and engineers' hands; and BlastIQ Insights, which enables the tracking of key performance indicators and comprehensive document storage. These technologies work together to offer customers improved productivity, with blast-loading instructions and rules being instantaneously and digitally communicated to field operations to ensure the right explosive product and quantity is used at the right place and initiated at the right time.