Selecting the right drilling equipment and tools plays a key role in determining overall quarry productivity and efficiency. Claire Symes reports

Estimates suggest that drilling and blasting operations can account for up to a third of the total operational costs of some quarries, so maximising the efficiency is important. But the cost of choosing the wrong equipment can be significant and will also impact on the quality of the aggregate and performance of the whole quarry.

The challenge of selecting the right combination of drilling rig, drill string and tools is complicated by the fact that every quarry is different and there is no 'one size fits all' solution. The choice will be dependent on a wide range of factors including the geology, size of benches, end use of the aggregate, proximity to the local community and acceptance of new technology.

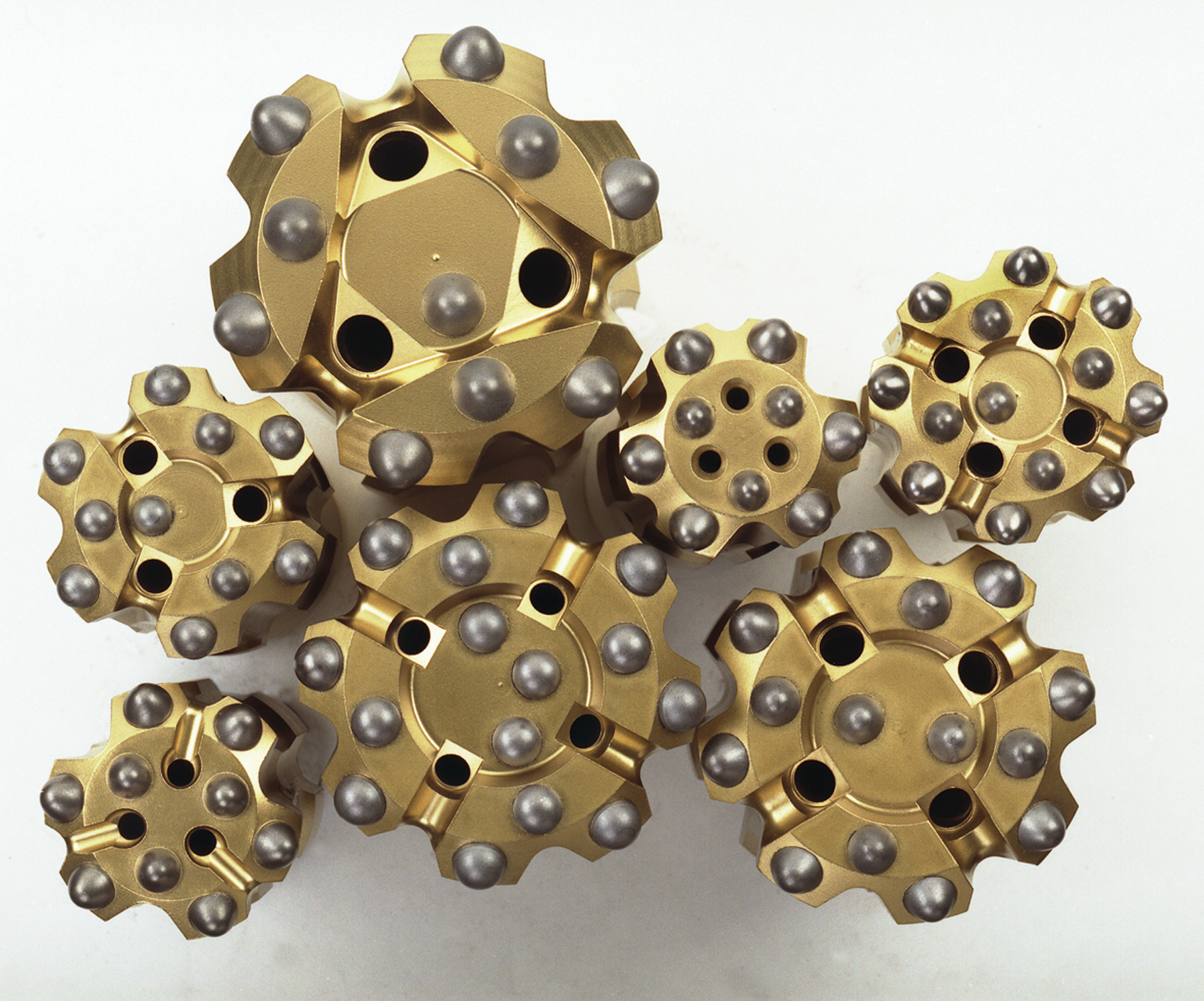

There are several types of drilling available to quarry operators today. Percussive drilling, which is also known as hammer drilling, is the most common method used in quarrying because of its suitability for use with a wide range of rock types. Both top hammer and down the hole hammer (DTH) rock drills are used in percussive drilling.

Rotary crushing techniques are common in oil well drilling. "Rotary techniques had become popular for drilling blast holes in rocks with a high compressive strength," said

In top hammer drilling, the rock drill is mounted on a cradle that runs along a feed beam. The force is transmitted to the cradle by a chain or screw driven by a pneumatic or hydraulic motor.

"The main focus of recent developments in hammers for percussive drilling has been to improve efficiency rather than to increase power," said Lindfors.

With rotary crushing, energy is transmitted to the drill bit via a tube that rotates and presses the roller bit against the rock. Applying large consistent forces while rotating the drill bit causes tension to build up, cracking the rock to release chippings.

The choice of drilling technique can depend on cultural differences, as much as the technical difference, and the preferred options vary considerably. "In Germany, a lot of quarries are located close to villages, so operators tend to use smaller diameter holes with taller benches to minimise the impact," said Lindfors.

"In the UK there is a general preference for DTH drill rigs but in the rest of Europe top hammer rigs are more popular. In the US, quarry operators want to use holes that are as big as possible - often in the 150 to 200mm diameter range - and they prefer to use top hammer drill rigs. There is a trend towards using bigger holes but this requires a larger blast, which often has an adverse impact on the finished quality of the aggregate." Stirling said, "There is a general perception that DTH rigs are simpler and top hammer rigs are faster. This isn't always the case and the selection of the rig used to be based on how things had always been done but other factors are now influencing the decision. The cost of fuel has helped to increase acceptance of top hammer techniques, which are up to 40% more fuel efficient than DTH methods." The type of rigs used for each of the drilling techniques also varies around Europe. "Some companies want very basic rigs but there is a general move towards hi-tech rigs, which is being driven by legislation to reduce noise, lower emissions and minimise manual handling," said Stirling. Atlas Copco launched the first drilling rig featuring GPS control for hole positioning and drilling records last year and uptake was expected to be mainly in more developed areas. "We have seen companies working in Central and Eastern Europe quickly embracing the new technology."

The hole story

The benefits of straight hole drilling

• Fewer drilled holes - optimised drilling pattern with increased burden and spacing

• Reduced consumption of explosives, which can account for 40 to 50% of drilling costs

• Longer service life of steel components

• Even fragmentation, which improves crusher productivity

• Less secondary blasting

• Smoother, more even benches and less back-break

• Less risk of jammed tools

• Improved safety through better blasting control

• Lower drill rig and tool maintenance costs

• Reduced fuel costs

• Less downtime

• Lower overall operating costsDrill holes are characterised by four factors - diameter, length, straightness and stability. Most equipment manufacturers can provide help with suggesting the best combination of hammer, drill string and drill to achieve the right hole characteristics.

"Usually we work with a customer to get the right solution for their individual site," said Lindfors. "We start with the ideal hole size needed for the geology and end result and work backwards to find the equipment to achieve this." The drill hole diameter will depend on the size of rock fragments required after blasting, the type and size of explosives, the quality of the fragments and permitted ground vibrations during blasting. Hole depth often influences the choice of drilling equipment and drilling in soft rock may call for the use of linings to prevent cave-in or blockage before charges are laid for blasting.

But to get the best from a blasting operation, the drill holes need to be as straight as possible. "Achieving hole straightness is the top priority when selecting equipment," said Stirling.

Lindfors agreed and explained, "Straighter holes make for easier and faster drilling. The less bending and shearing stresses there are on the drill string, the longer the tool service life. But it also offers better blasting results with controlled fragmentation and less risk of flyrock, back-break and ground vibrations. Other benefits are smoother benches and improved site safety." There are a number of factors that influence hole straightness, including the rock properties, drilling method, the condition, power and set up of the drill rig and, most importantly, the design of the drilling tools.

"Using sophisticated monitoring systems that are now available on drilling rigs will also have an effect, not only on the straightness and quality of the hole, but also on the service life of the tools," said Lindfors. "With the right system it is possible to achieve hole deflections of less than 2%." Lindfors said that if the drill rig is correctly and stably positioned, the feed aligned properly and the drill parameters adjusted to match the rock properties, then it is possible to reach an acceptable level of hole straightness with a standard tool solution. "Although some rock types may call for customised equipment to minimise hole deviation and optimise drilling patterns," he added.

Using drill strings with better connections rather than separate coupling sleeves can reduce drill string play by up to 50%. This better transfer of energy from a stiffer rod can also improve hole straightness and drilling efficiency. "Generally, matching the diameter of the drill string to the diameter of the piston in the drill gives the maximum efficiency," said Lindfors.

"Improving hole straightness by just 3% and using it to increase your burden and hole spacing can reduce drilling and blasting costs by at least 5%. When you consider that drilling tool costs account for between 5 and 10% of total drilling and blasting costs, it is worth investing time to get the right solution." Positioning of the drill holes is also critical, according to Stirling. "Addition of GPS to a rig monitoring system can increase the accuracy of drill hole collaring to ensure the planned burden and spacing is achieved on site. Conventional positioning uses a high factor of safety as a fail safe but this can be reduced using GPS, lowering the cost of blasting work by up to 30%."

Maintenance matters

Even once the optimum drilling solution has been selected, the drilling performance can drop over time. "Depending on the abrasive nature of the rock, the drill bits can become blunt and worn," said Stirling. "There is a growing trend in Europe for operators to carry out on-site grinding to extend the service life of drill bits.

"Grinding in some countries, such as Norway and Sweden, has been standard practice for many years but in others, including the UK, grinding is not as widespread but is growing in popularity. The main reason for this difference is probably down to the type of rock - I know of one quarry in Africa where the bits need grinding after each metre of drilling.

"Grinding is now becoming more popular because it can add 70% to the service life of drill bits, which not only represents significant cost savings but it is also more environmentally friendly as it creates less waste."

Drill development

With the greater use of contract drilling in quarry operations, there is growing demand for faster drill rigs but other customers still want basic rigs.

"Some of the latest DTH rigs operate at 30 bar, rather than the 25 bar which is considered standard," said Stirling. "This helps to speed up the drilling rate but not everyone wants such high powered rigs as they do not suit every rock type. We offer DTH rigs that operate from 12 to 30 bar and top hammer rigs from 12 to 40kW.

"The difference in demands both from the rock type and production means that drilling solutions, right from the specification of the rig through to the drill bit always have to be bespoke. That is one thing in drilling that will never change"