Following its debut at

The Terex Finlay I-1310RS impact crusher, a single crushing, screening and stockpiling unit on one chassis, is now entering production after being launched at the Bauma Trade Fair in Germany.

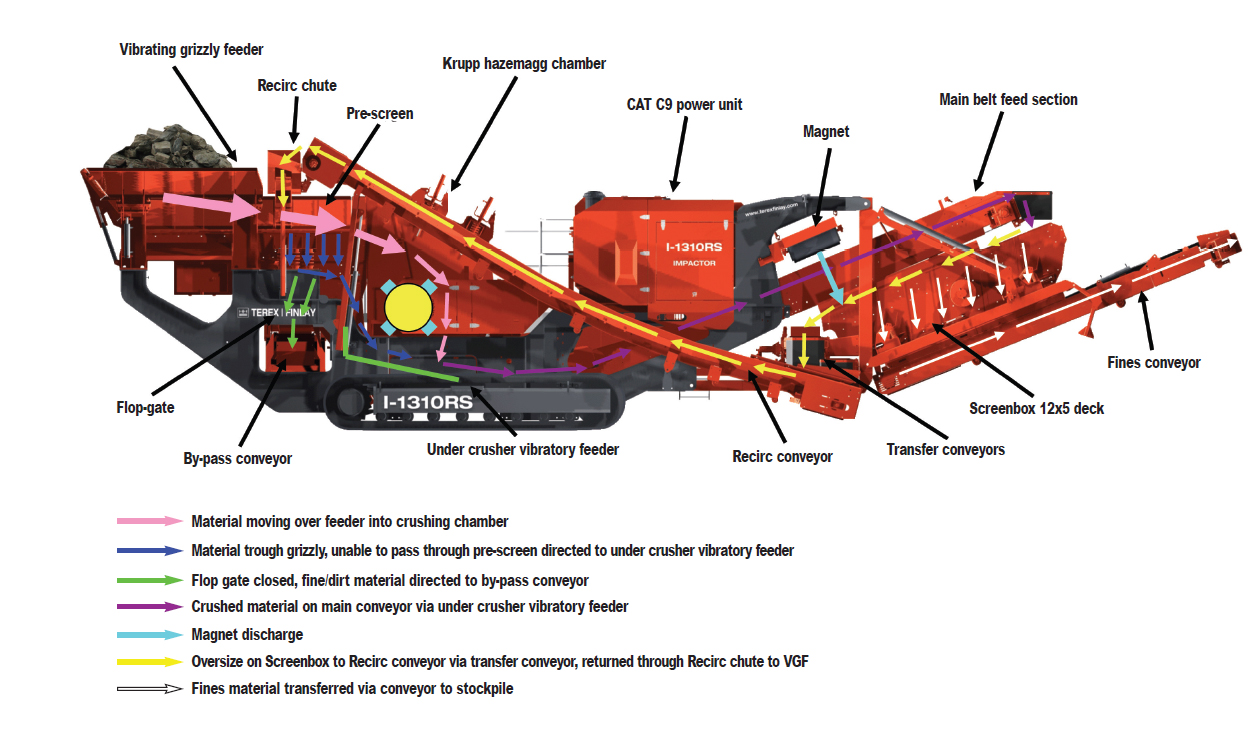

The model comprises a heavy duty vibrating grizzly feeder with integrated pre-screen and under-crusher vibratory feeder to prevent belt damage. It also incorporates a 3.66m x 1.52m screen which feeds oversize material back to the hopper via the recirculating conveyor.

A particular feature is an advanced electronic control system which ensures that the operation is as simple as possible.

Terex Finlay product manager Gordon Dunn pointed out the advantages of the two-in-one system. "With a traditional set-up, the operator would need two machines on the site: a crusher feeding a screener sorting out the crushed aggregate. There may be three classes of product from the screener, and the oversized product would then have to be re-crushed, requiring a wheeled loader or excavator to carry back the material. Basically it's an additional handling operation." With the I-1310RS, material is fed into the crushing chamber and gets fragmented, and then it passes onto the integrated double deck screen. "The oversize product gets put into a chute and then fed into a recirculating conveyor which goes back up into the primary feed hopper and then re-crushed. It is two machines in one: one engine, one control system and one set of tracks," said Dunn, pointing out that the I-1310RS offers saving in terms of reduced handling and lower service costs compared with other methods.

The versatile machine's main markets are quarrying, but recycling is a growing sector. The company also manufactures other impact crushers. The I-1310 is basically same, but doesn't have the recirculating facility or screen. The I-1312 has a much larger crushing chamber than the 1312; handles a larger tonnage and is a heavier machine.

"We have a number of the RS units already in operation and we are selling quite a few internationally," said Dunn.

Also launched at Bauma was the C-1540 cone crusher, available in two configurations the C-1540 with pre-screen option and the C-1540RS with recirculating screen configurations. The crusher has a metal detector on the hopper with a self-clearing facility.

"Usually within the crushing process you have primary, secondary and tertiary procedures," explained Dunn. Traditionally the jaw crusher is used in the primary process to achieve the largest reduction ratio. You then proceed to an impactor or cone crusher. It depends on the rock characteristics. If it's an abrasive material you tend to find that the jaw crusher accompanied by a cone crusher is required to get the desired size. If it is a softer rock a jaw crusher would be accompanied by an impactor or just impactor on its own." One of the most notable characteristics of the C-1540 is the 1.82m by 1.21m single deck pre-screen, in front of the cone chamber. It basically reduces wear costs on the chamber by only crushing what is needed, said Dunn.

"The pre-screen system can be bypassed if desired, depending on application. The metal detector detects anything on the feed belt before it goes into the cone chamber. Normally, the belt comes to a stop and the operator has to look for the part manually, and dig it out. With the C-1540 the belt will automatically stop. The operator can then retract the conveyor and discharge the contaminated feed material on the belt via a side-chute. The operator does not have to leave the cab, saving time and effort."