Haver & Boecker Niagara will highlight its latest screening equipment, technology and solutions for the mining industry at the 2024 MINExpo International show in Las Vegas (24-26 September). The company is showcasing a variety of equipment in booth 8633, including a full-size Niagara F-Class vibrating screen.

“MINExpo presents an exciting opportunity to have great conversations with mining industry members and for both new and existing customers to see our mineral processing equipment up close,” said Karen Thompson, president of Haver & Boecker Niagara’s North American and Australian operations. “We are proud to be known not just as an equipment manufacturer to our customers but as a partner with innovative end-to-end solutions to improve their operation.”

Haver & Boecker Niagara will highlight several solutions at MINExpo, including:

Niagara F-Class vibrating screen

Haver & Boecker Niagara will display a full-size Niagara F-Class vibrating screen in their booth. The next-generation F-Class features new technology for simplified maintenance combined with maximum performance and longevity. It is now primarily manufactured with vibration-resistant lockbolts instead of the traditional welding used in previous designs. Lockbolts are more effective at maintaining structural integrity during the demanding load-bearing, high-vibration operation of a vibrating screen while making maintenance more convenient, safer and cost-effective. Bar rails are now fastened to the cross beams with lockbolts, making them easy to exchange if they become worn.

The machine’s double eccentric shaft assembly creates a constant stroke to maintain g-force during material surging, providing constant material stratification to ensure product specification. It also creates a dynamically balanced system that transmits virtually no vibration into the structure — or chassis — preserving the integrity of the structure while also allowing for multiple machine installations. The upgraded design retains the technical benefits the original F-Class is known for, such as enhanced material stratification and reducing blinding and pegging.

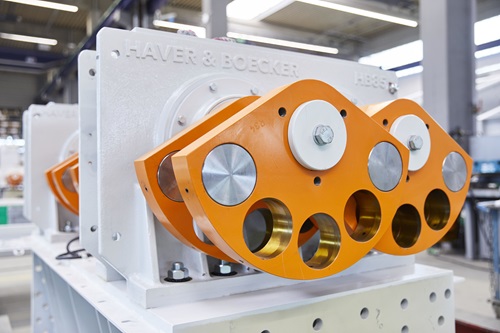

Niagara Exciters

The company will also exhibit Niagara Exciters, its signature brand of vibrating screen exciters. They provide increased service life and reduced maintenance and are standard on Haver & Boecker Niagara’s high-capacity exciter-driven vibrating screens, the XL-Class and L-Class. The company engineers Niagara Exciters to set the required stroke, frequency, and exact static moment for each application for improved screening performance.

Pulse Diagnostics

Additionally, Haver & Boecker Niagara will feature its Pulse Diagnostics portfolio, which monitors the health of vibrating screens and identifies issues before they become critical, improving operations’ productivity and proficiency. The suite combines Pulse Vibration Analysis, Pulse Condition Monitoring and the Pulse Impact Test to give mining producers a more holistic view of their individual machines and allow them to maximise uptime and screening efficiency through planned maintenance. Booth visitors can see Pulse Diagnostics firsthand at the interactive 'Check Your Pulse' kiosk.

Rhino Hyde liners

The company will also highlight Rhino Hyde Liners, which originally debuted at AGG1. Rhino Hyde liners are a critical component in the mining setup process and offer superior abrasion resistance when installed on key wear areas of chutes, hoppers, vibrating screens and more. They are essential for reducing wear on equipment at each point of the operation, from hauling to screening and material handling.

Experts will be in the booth to educate about these and additional innovative, end-to-end solutions. To learn more about Haver & Boecker Niagara’s global mineral processing products and services, visit www.haverniagara.com.