Last year, BRV, the Austrian Building Material Recycling Association, reported new regulations coming into force banning the disposal in landfill of waste that is “suitable for recycling and other forms of recovery”, including material from road and concrete demolition works, railway ballast, asphalt and more.

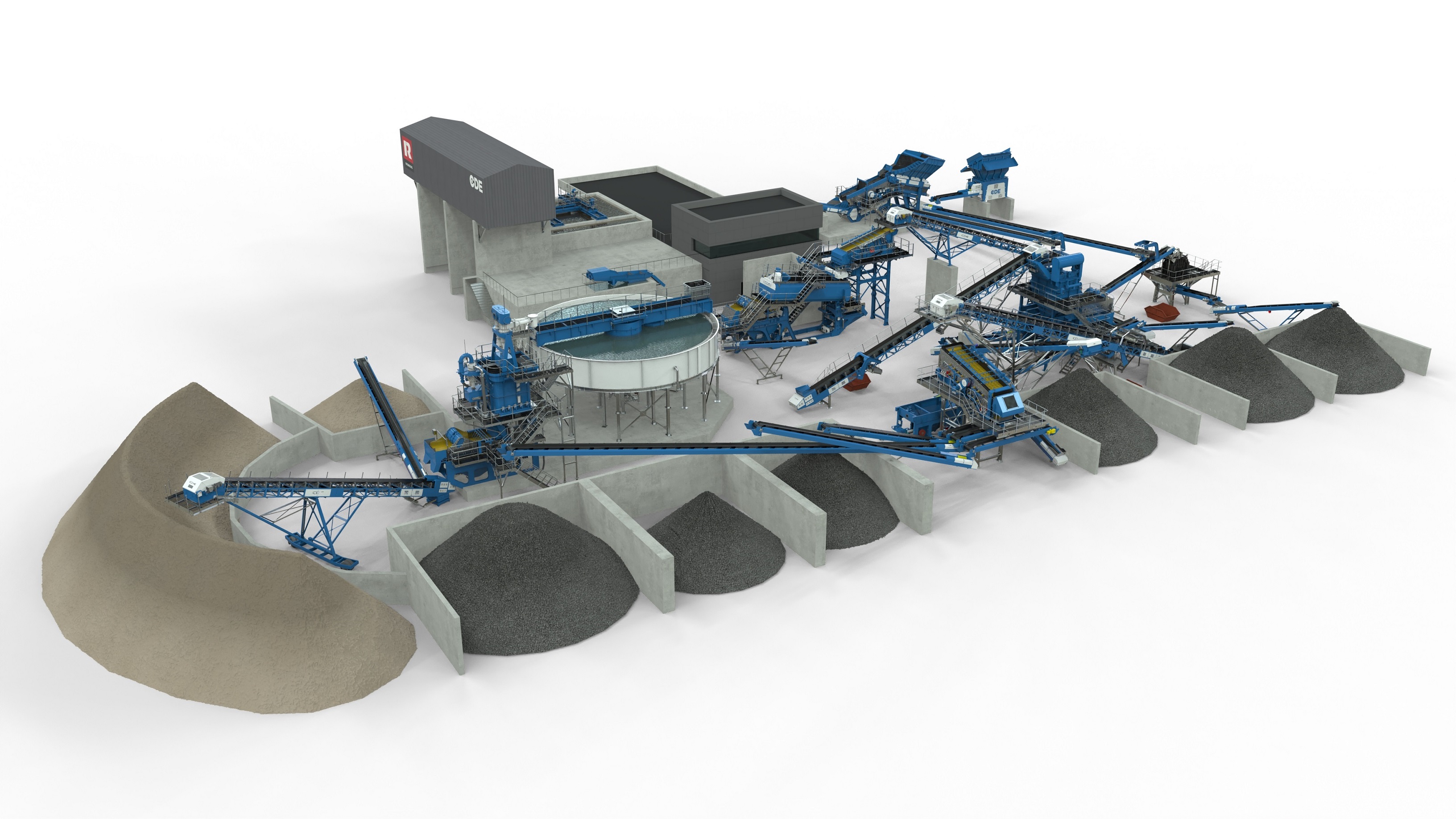

In light of emerging legislation and to reinforce its commitment to the advancement of the circular economy, Rhomberg is now partnering with CDE to engineer what will be the region’s largest C&D waste recycling plant when commissioned in autumn 2022.

With a processing capacity of up to 200 tonnes per hour, the turnkey plant will equip Rhomberg with a robust and flexible solution engineered to handle demanding and highly variable inert waste streams originating from the westernmost parts of Austria, where the availability of virgin resources is limited.

Now in its fourth generation, Rhomberg Bau, a family-owned enterprise founded in 1886, currently employs around 800 people and has locations and subsidiaries in Austria, Switzerland and Germany. A full-service provider, it offers solutions and services for all phases in the lifecycle of public and private sector construction projects. Its quarry and resource centres produce approximately 500,000 tonnes of material annually through quarrying, processing and recycling activities.

The new CDE solution will further strengthen the capabilities and capacity of its recycling unit, which collects and processes non-hazardous waste to recover valuable resources that can be returned to the construction sector as high-quality building materials.

Uniquely, the cutting-edge solution offers Rhomberg unparalleled flexibility over the volumes of each end product. As such, if a single fraction is not required in any significant volume, Rhomberg can crush it to maximise the volume of the preferred material fraction.

Mass flux is also precisely monitored, providing Rhomberg with exact mass balance throughout the plant, including oversize and waste by-product such as filter cake.

CDE’s regional manager for the DACH area, Christoph Baier, says the project marks the beginning of an exciting new chapter for Rhomberg.

“When commissioned, its new plant will be the most advanced of its kind in the region made possible not only by our industry-leading process knowledge and proven technologies but by a partnership underscored by the shared desire to accelerate the pace of change in our sector and champion the use of recycled construction materials.

“Construction of a standard single-family home,” he explains, “requires around 440 tonnes of mineral raw material. To put that in context, with their new CDE solution, Rhomberg would be able to process this volume of material in under three hours.”

A recent report commissioned by the Vorarlberg state government found that the Dornbirn district, where Rhomberg Steinbruch is based, generated almost 400,000 tonnes of excavated materials in 2019.

“This single plant enables Rhomberg to screen, scrub, wash and classify that waste stream,” Baier adds.

Rhomberg Bau managing director and head of construction & resources, Rupert Grienberger, says the new plant demonstrates Rhomberg’s commitment to the region.

“We are a leading force for change and a vocal advocate for the use of construction materials recovered from C&D waste. We recognise the value in these inert waste streams but also their complexity and variability, characteristics which necessitate an equally advanced processing solution to be able to handle efficiently. Our direct relationship with CDE coupled with its industry expertise and understanding of our needs gives us great confidence in this partnership and the positive role the plant will play in the circular economy in western Austria.”