Telestack, a major global dry bulk materials-handling solutions manufacturer for industries including quarrying, had a major presence at Hillhead 2022 near Buxton, Derbyshire, England. The Omagh, County Tyrone, Northern Ireland-headquartered, Astec Industries-owned company was promoting its near 30-strong Zero range of track-mounted conveyors, mobile hopper feeders and radial stacking conveyors.

The term Zero relates to units that have no engine fitted. Telestack Zero mobile tracked conveyors and hopper feeders incorporate electric hydraulic power packs to run the tracks in parallel with electric drives to operate the conveyor section. The engine is completely removed from the machine.

The Zero range offers quarrying customers a greener alternative to the sector’s traditional track-mounted diesel-hydrualic conveyors and builds on Telestack’s more than three decades global supply of electric-powered conveyors for static applications and the port industry.

Speaking to Aggregates Business at Hillhead 2022 stand, Padraig McDermott, Telestack’s international sales manager, says customers are attracted to the reduced complexity, ease of running and quick set-up times of the Zero range.

Speaking to Aggregates Business at Hillhead 2022 stand, Padraig McDermott, Telestack’s international sales manager, says customers are attracted to the reduced complexity, ease of running and quick set-up times of the Zero range.

Pointing to an on-stand, 500-tonnes-per-hour Telestack conveyor, he says: “That is run by two 11kW motors – 22kW, but you do not use all that. Whenever we manufacture a diesel-hydraulic conveyor, we must fit a 37kW engine in it to account for hydraulic losses in pumps, motors and hydraulic lines. Generally speaking, hydraulics is not an efficient technology, because a substantial amount of power is lost in the process of converting energy.

“Typically, you are using 30% to 40% less power by going electric. You are not only matching your production volumes, but you’re also likely increasing it, as there is not a lot of maintenance needed. Noise emissions will also be considerably reduced when you compare an engine to quiet electric motors. This is particularly advantageous when working close to built-up residential areas or conservation areas.

“You can power your [Zero range] conveyor from other equipment like the crusher or screener or mains power. If your provider is generating their electricity by renewable technology, then your carbon footprint is drastically reduced.”

Taking the Zero range one step further at Hillhead, Telestack launched its first Zero ‘Battery’ conveyor. McDermott explained the operation. “The Zero battery machine incorporates a battery pack which is used for tracking, relocation and set-up. The battery pack provides power for approximately one to one-and-a-quarter minutes of tracking. This allows the customer to load the machine, transport it to site, offload and bring it to the working area. When in position the conveyor is connected to mains power or a primary power source to run the conveyor section.

“The battery pack we have developed for our conveyors is a modular kit. We can slot it into a bigger machine and increase the module size with extra cells in the battery to gain the required throughput.

“Once you plug in to a mains supply, there is a trickle supply to the battery, so you can recharge it in four hours.

“With regard to return on investment, typically electric-powered tracked conveyors are more expensive to buy, but your return on investment is quicker.”

McDermott says that “around 90%-95%” of tracked mobile conveyors working in quarries had been diesel-hydraulic powered “until recently”. “It could be that this year we see 25%-30% of our quarry conveyors powered electrically.” That is a significant shift - driven by the cost of fuel and the customer’s desire to become more efficient in their operation

Scandinavia is likely to generate the biggest regional demand for the Telestack Zero range, McDermott believes, followed by well-populated European cities, such as Berlin, Frankfurt and Strasbourg, where there is a big push to reduce carbon emissions and work-site noise levels. He continues: “After Europe, I think the United States and Australia could be good markets for the range. The sharp rise in the price of diesel fuel is as much as a shock to them as it is to us!”

Cement manufacturers face strict environmental regulations with alternative fuels. This way, they fire calciners and main burners in an efficient and sustainable manner. BEUMER Group develops single-source solutions to convey, store and feed the differently composed materials. Among other things, the overall systems are made up of specially developed individual components.

Cement is the most used building material worldwide and the usage rate is continuously growing. However, manufacturers must comply with ever stricter environmental regulations in order to get air pollution under control. Depending on the processes used, the emissions from producing cement are at 0.6 to 0.99 t of CO2 per ton of cement. The CO2 emissions from this sector are estimated to account for seven to eight percent of the overall global carbon dioxide emissions. An approach to sustainably reduce greenhouse gas emissions and production costs is to increase the use of alternative fuels.

Fluid materials like waste oil or solvents, but also solids for example, are used instead of coal and gas. The majority is composed of municipal and industrial waste, such as plastic, paper, composite material or textile mixes as well as wood pellets. The use of entire or shredded waste tyres is also welcome. The calorific value of the rubber from waste tyres is comparable to that from hard coal, and the iron from the reinforcement can be incorporated mineralogically into the cement. This minimises the addition of ferrous corrective substances. Alternative fuels are available in large quantities and at low costs and can be disposed of completely in a safe high-temperature process in the rotary kilns at the cement plants. Thus, these materials do not have to be landfilled or otherwise disposed of.

As different materials have different calorific values, the complete household waste cannot simply be fed into the combustion process in the kiln. Especially in countries where waste separation is not developed like in Europe, the challenge is huge. How the alternative fuels are composed and how they are used often also depends on their availability in a determined region and, in particular, on the economic aspects. In addition, the materials must fulfil determined quality requirements. Some operators for example only use processed waste with a defined minimum calorific value and low heavy-metal content. At this regard, the alternative fuel often may only have a determined particle size and a determined density. The moisture content is also important.

As a system provider, BEUMER Group develops tailor-made solutions for the entire material flow chain from unloading the delivery vehicle to storing, weighing, conveying and control feeding of solid alternative fuels. BEUMER Group also provides fully automated systems that can control feed, singulate and convey large and heavy tyres to the inlet of the rotary kiln. BEUMER Group supports the cement manufacturers with its intralogistic solutions in modernising their plants in sustainable and cost-efficent ways. "Our know-how and tailor-made systems permit us to optimise our customers' processes," says Jan Tuma, chief sales officer (CSO), BEUMER Group, Czech Republic. The user receives everything from one source, thus having a unique contact. In addition to a comprehensive range of reliable systems for handling with alternative fuels, the specialists also focus on planning logistics and customised conveying and storage solutions, including crane halls and steel structures.

"The material flow chain is implemented with the single components of our BG OptiSeries," says Tuma. "We have developed these different systems in our company - a clear unique feature on the market". The systems are designed to meet the requirements for functionality and performance in daily operation.

The material prepared for combustion in the kiln is usually supplied in moving-floor trailers. The hydraulically controlled moving floor moves the load outwards on the conveying system. "All conveying systems supplied and the accompanying equipment are intertwined like toothed gears to ensure steady fuel feeding," explains Tuma. "At this regard, we can install our unloading station BG OptiBulk at our customers.” This system is suitable for inhomogeneous material that is difficult to handle. Such materials have a low bulk density, high moisture and a large grain size. In addition, this system is suitable for explosive substances. In addition to tippers and moving-floor trailers, which are sometimes in use, trucks can also be unloaded quickly and easily. The system consists of a chain belt conveyor and lateral steel walls.

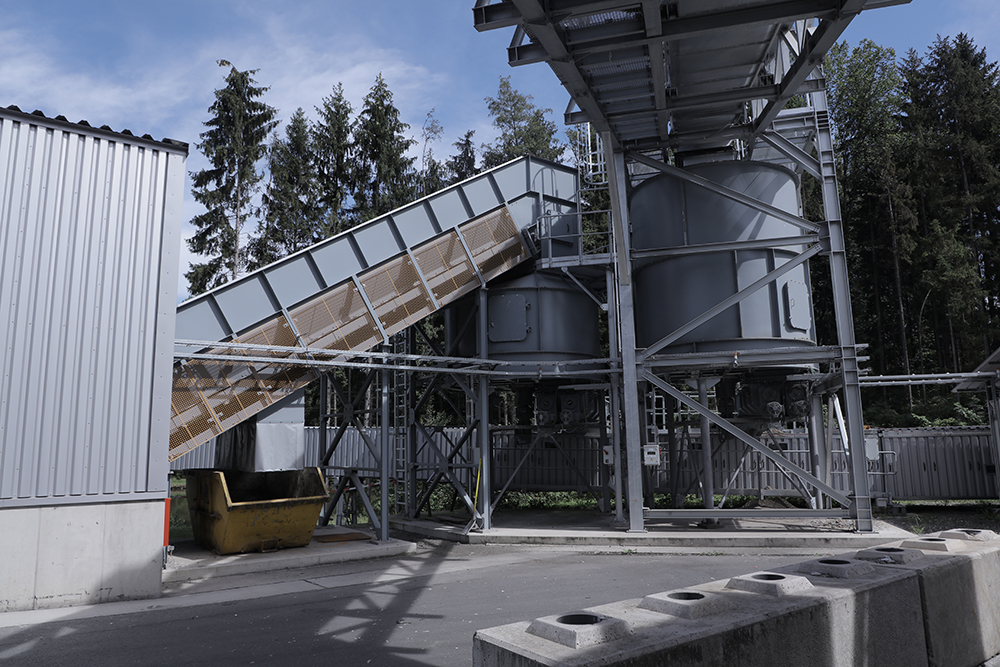

Pic: BEUMER Group

A further possibility to empty trucks and moving-floor trailers is given by the BG OptiDock. This station is also suitable for inhomogeneous material like alternative fuels or biomass. The BG OptiDock is composed of a receiving box and a screw floor. It guides the raw materials and the alternative fuels coming from the moving-floor trailer and the truck on a feeding system. The receiving box is equipped with a rubber gasket and, if necessary, with a hydraulic pump in case the vehicle is not available. It permits continuous unloading of the semi-trailer.

“The material falls from the unloading station into the BG OptiFeed screw weigh feeder with a connected buffer bin. This screw conveyor with weighing cells is suitable for completely different materials – that means it’s ideal for the continuous feeding of alternative fuels or raw materials," says Tuma. “Since the screw conveyors are positioned on the weighing cells, it can always be seen how much material is extracted. The regulation ratio is max. 1:10 and the maximum feeding accuracy between one and two percent.” In addition, the completely closed screw weigh feeder is protected against dust.

BEUMER Group also offers a BG OptiFeed Duo. This solution has been designed for the continuous feeding of bulk material to two separated feeding points in one process, for example when the preheater tower has two inlets. The material is then stored in a buffer bin and taken off by two single-screw conveyors or one double-screw conveyor.

To transport the alternative fuels to the calciner and to the main burner, BEUMER experts, depending on the application, evaluate different variants of mechanical conveying systems, which for example include the pipe conveyors. "This conveying technology is not only eco-friendly and requires low maintenance", describes Tuma, "its enclosed type of construction also protects the environment safely from material falling down and emissions. Another advantage is the elimination of dust development on the running line". Due to its ability to navigate curves, considerably fewer transfer towers are required compared to other belt conveyors and the system can be customised to the individual routings. "If necessary, we can further equip the conveyor," says Tuma, "for example with a scraper conveyor in order to minimise clean-up, or with a dedusting filter".

A further efficient possibility is the U-shape conveyor. It can be simply integrated and is also suitable for long distances and rough terrain as well as horizontal and vertical curves. Just like in the pipe conveyor, the material conveyed is protected against external influences such as wind, rain or snow and the environment against possible material loss. This conveying solution is suitable for coarse but also for very fine material.

"At the feeding point, the U-shape conveyor is open like conventional troughed belt conveyors," explains Tuma. "A special idler configuration brings the belt in a U-shape". This way the material conveyed reaches the discharge station. An idler configuration similar to that for the shaping is used for opening the belt.

Conveying elements lead the material to the discharge screw conveyors of the BG OptiLock construction series. The airlock of this system solution protects the pyroprocess from the infiltrated air, i.e. the air that additionally and uncontrollably enters from the outside with the fuel. Also, the BG OptiLock is equipped with load cells and transfers the bulk material continuously to a screw conveyor, which feeds the calciner. The speed of the discharge screw conveyor is controlled so that the shown weight of the entire system and the real material volume in the container is constant. "As the material can catch fire, all systems are carried out according to the ATEX directives," says Jan Tuma.

As a single-source provider, BEUMER Group has substantial competence in handling with alternative fuels and can support the owners of cement plants efficiently - all within a short period of time. All components are complementary and ensure the continuous and economical feeding with alternative fuels.

Martin Engineering CEO Emeritus Todd Swinderman and the company’s process engineer Dan Marshall have spoken to Aggregates Business about mistracking bulk material-handling conveyor belts and potential remedies.

“On any belt conveyor system that moves bulk materials, the belt must run straight and true to maximise its life, minimise fugitive material and safety hazards, and achieve high system efficiency,” says Swinderman. “There can be many consequences of a mistracking belt, but all result in higher costs and increased maintenance. Even a slight belt misalignment can lead to a variety of issues, from small annoyances to full-blown catastrophes. The most obvious effects include spillage and dust that require personnel to do clean-up, which is unproductive work that introduces risks from activities in close proximity to the moving conveyor.”

Swinderman says spillage from non-centred cargo can often get into idlers and pulleys, reducing bearing life and causing them to seize, leading to friction damage on the belt and potentially starting a fire. He continues: “A misaligned belt can also come in contact with the stringer, causing fraying, shredding or splice damage. Great lengths of valuable belting can be destroyed with surprising speed, and even the support structure itself can be damaged. A compromised bracket or support can cause a catastrophic idler failure, which could damage other components of the system and require extensive downtime to repair. Further, there is potential for injury from a damaged belt or loose idler not to mention the increased exposure to injury from too frequent a need to clean.”

“I’ve been working around conveyors for 20 years, and I’ve seen thousands of belts,” observes Marshall. “I’ve seen just about every problem that can be caused by a mistracking belt, but one thing I’ve never seen is a belt that runs true right out of the box. All conveyors, no matter how well designed and built, have some belt wander.”

Swinderman adds: “A wide variety of circumstances can lead to mistracking, and operators have tried many things to correct the [belt] alignment. Some have elected to place an obstacle such as a block of wood in the belt path, so it won’t travel too far out of line. This occasionally improves the situation, but more often it’s just temporary and the belt will eventually slice through the obstacle.

“Many operators have realised that pivoting an idler is a quicker and more effective way to steer a belt. This common approach is called ‘knocking an idler’, striking it with a hammer to move it slightly and realign the belt.”

Swinderman notes that equipment manufacturers have also designed components to help align a [conveyor] belt, and these solutions can be successful in specific applications. “They include specially shaped rollers, angled idlers and devices that apply pressure to the belt edge to push it back in line,” he explains.

“While these mechanisms can improve a belt that’s consistently off-centre in one direction, they do not react to dynamic belt movement, meaning that they don’t correct intermittent belt wander,” says Marshall. “To combat such changing conditions, engineers designed the tracking idler. Unlike the edge-correction approach, the device senses belt movement in either direction and pivots the idler slightly to steer the belt back into position. It doesn’t apply a great deal of force to the edges, which can damage a belt and splices. When the belt is running true, it remains centred, and when it senses a misaligned condition, it gently corrects the belt.”

Unfortunately, as Swinderman highlights, to accommodate limited space availability, tracking idlers typically have short sensing arms. This requires a fairly large belt displacement to create a small movement of the idler. “While these designs do tend to improve tracking, there are limits to how much correction they can deliver, and short sensing arms can actually pinch a belt if the idler pivots too far. To combat this, some operators choose to ‘tie off’ a tracking idler to limit its movement. While the practice can help preserve the belt, it doesn’t address significant mistracking.”

To overcome the limitations of existing belt alignment devices, U.S.-headquartered Martin Engineering has invented and patented a multi-pivot belt tracker, the Martin Tracker, which employs sensors, pivoting idlers and geometry to align a wandering belt. The sensors avoid pinching the belt, and the engineered geometry amplifies any detected misalignment to create a greater pivot.

Swinderman explains how they work: “Multi-pivot belt trackers like the Martin Tracker use longer arms than other designs, positioning the guide rolls further from the pivot roller, as well as closer to the belt edge. The closer proximity allows guide rolls to sense very slight misalignments and make immediate corrections. Rather than waiting for a powerful mistracking force, the longer arms require considerably less pressure to move the pivot roller. The result is better correction with no pinch points and less wear on conveyor and tracking equipment, for a longer and more efficient service life. Specific designs are available for both the load-carrying belt path and the return run.”

“Installing trackers is the economical solution, but operators should do a full analysis and consider also addressing other causal issues,” says Marshall. “By focusing solely on belt alignment, plant personnel may miss other opportunities to increase production and relieve some of the burden on their system.”

Swinderman stresses that keeping the belt centred and moving quickly is the key to high production, controlled operating cost and a safer workplace. “Misalignment causes downtime and costs money,” adds Marshall. “But nothing causes more downtime and expense than a destructive belt fire or other catastrophe as a result of inattention to mistracking problems.”

WCCO Belting says it has seen some impressive results from quarrying customer field-testing of its Direct X conveyor belting. Replacing three- and four-ply texture top and back standard industry belting in U.S.-based aggregate crushing applications, WCCO’s two-ply Direct X belting is said to have doubled belt life, reducing belt replacement and production downtime, and achieved claimed energy savings of 15%. Direct X belting is also said to have a 20% lighter carcass than the previously deployed three- and four-ply standard industry belting.

Mike Schroeder, WCCO Belting product specialist, said: “The field tests proved that the Direct X belting delivers on performance, efficiency and longevity. Some people look at conveyor belting and think that it is all about ‘buying on [lower] price.’ That is a misconception. If you buy a thicker [three- or four-ply] belt, for example, that is 20-25% more cost [than a two-ply]. Sometimes, belt replacement can cost just as much as buying a new belt. In the belting world, you get what you pay for when it comes to quality.”

Minnesota-based Ferguson Aggregate and Crushing is among WCCO Belting customers to have trialled the Direct X belt. Adam Wirtjes, the company’s crushing supervisor, said: “We typically run three-ply and four-ply conveyor belting because of the aggressiveness of the work – heavy material with rebar sticking out. Belts can take on large punctures and tears within the first season and not last to the next. When I first saw WCCO’s Direct X belt, I was a little sceptical the two-ply construction would hold up. It did take on a couple punctures, but they were smaller and fewer than in the thicker belts we had been using. Not only is the Direct X continuing to run into the next season, but it was also easier to install and had noticeably less drag while running the conveyor.”

The Direct X and all other WCCO Belting’s products are designed and manufactured at WCCO’s North Dakota, USA, facility.

Coveya’s Invader 45 is designed to handle big jobs in tight spaces. At just 4m or 6m long and 450mm wide, the Invader 45 is lightweight, portable and powerful, shifting up to 50 tonnes of material per hour. Being fitted with a conveyor belt that can handle the pace is imperative to the success of the Invader, which is why Coveya turned to Northern Ireland-based conveyor belt manufacturer Smiley Monroe when choosing the right belt for the job. The Invader, fitted with customised Smiley Monroe cleated conveyor belts, has been used for everything from excavating basements in central London to restoring the floors in the historic Eton College, in Windsor, Berkshire, England.

Maximising uptime and long service life are fundamentally important to Coveya, which offers the Invader both to purchase and as part of its hire fleet. When approached to provide suitable belt options, Smiley Monroe engineers worked with Coveya to recommend a customised hot moulded belt that would provide the wear life and performance required for a wide range of applications, while being lightweight enough to allow the Invader to remain easily portable in confined locations.

“Breakdowns are often caused by belt damage or issues caused by a build of carryback material or spillage, so it was important for us as a supplier to safeguard against as many of these issues as possible when choosing the correct conveyor belt,” said John Hancock, Smiley Monroe business development executive.

Smiley Monroe engineers recommended a fabric-backed base belt with reinforced cleats (two per row) to provide the end user with a lightweight belt that runs smoothly at speed while providing adequate protection from carryback and material spillage when used at an incline. Manufactured at Smiley Monroe’s headquarters in Lisburn, near Belfast, the reinforced cleats are hot-moulded to the belt’s carrying surface to ensure superior adhesion and wear life – something which is imperative when dealing with construction and demolition waste and other harsh materials.

“As a company we have built a reputation for supplying reliable conveyors which get the job done. When our machines are out on hire, every hour is costing the customer money and so to suffer a breakdown can have major knock-on effects on their operation and consequently require us to provide a service team. Finding the right conveyor belt for the job was key and having a supplier like Smiley Monroe with so much knowledge, state-of-the-art manufacturing facilities and excellent customer service levels like our own has been instrumental to the success of the Invader,” said Martin Pillar, project manager at Coveya.

With over 40 years’ experience and three global production facilities, Smiley Monroe offers an extensive range of conveyor belt solutions supplying prestigious manufacturers of mobile equipment around the world, covering ten key industries including quarrying, construction and demolition, recycling and waste management, bulk material handling and road construction. The company’s conveyor belts can be customised to suit customer applications with side rail, cross-cleats or chevron patterns. Smiley Monroe conveyor belts can be supplied open (ready to splice), endless or as a Zip Clip mechanically fastened belt, said to be perfect for the original equipment manufacturer aftermarket or end users who wish to maximise uptime.