"Good housekeeping is the cornerstone of everything we do," says Nigel Mitchell, operations director at Blue Phoenix UK. "Health and safety, production efficiency, plant profitability, environmental impact, you name it, they are all compromised without high standards in day-to-day housekeeping.

"In fact, you can tell a lot about the culture of a place from its on-site housekeeping. And besides, when things are clean and tidy, it's much easier to see how a plant is running and where there are potential problems." That's especially the case for material spillages, buildups and blockages, all issues that Mitchell and his team have been on a mission to address in partnership with a leader in materials-handling solutions, Martin Engineering.

Blue Phoenix operates 11 plants in the UK stretching the length and breadth of the country, which together process more than 1.5 million tonnes of IBA each year. With operations across Europe, North America and Australia, Blue Phoenix is the world's largest IBA processor, specialising in recovering ash residues from EfW (Energy-from-Waste) plants. The process extracts the ferrous and nonferrous metals and produces a range of manufactured aggregates that meet standards such as the UK's SHW (Standard for Highways Works) 600 series for bulk full applications.

While it's an impressive circularity success story, it's not without its challenges – IBA is highly abrasive, containing a mix of concrete, glass and ceramics, with metal pieces that can rip belts and damage processing plants. Storing IBA outside means the material gets exposed to all weather conditions, so it can contain substantial amounts of moisture, causing it to become sticky and hard to handle. IBA's cementitious properties mean that it can generate its own hotspots during storage.

This can make IBA prone to material carry-back, resulting in spillages, buildups and blockages, which create safety risks and production inefficiencies. And that's on top of the extreme wear and tear on conveyor systems, including issues like belt-cleaner blades corroding to mainframes and tensioners seizing. To add to the processing challenges, EfW operators need to continually move their IBA on to Blue Phoenix, who, in turn, must process it continually and get the manufactured aggregate out of the gate in good time.

Unscheduled downtime seriously affects the supply chain, so keeping plants running efficiently is critical. Furthermore, all 11 Blue Phoenix plants in the UK are discretely housed inside industrial units, and each occupies a relatively small footprint. Hence, a clean and tidy operation is paramount.

Each plant is a network of approximately 20 belts, ranging from 600mm to 1600mm wide, mostly fast-running, many with small head drums, and some with eddy current separators.

The belts are made from PVC, which is durable but can be difficult to keep clean. "We'd had belt cleaners from another supplier at most of our plants, but we struggled with the lack of continual service support to ensure they performed at their optimum best."

Having had enough of the difficulties with other suppliers, Blue Phoenix turned to Martin Engineering in 2018, which led to the installation of QC1' Pit Viper' primary polyurethane blades on a few critical belts at five operations.

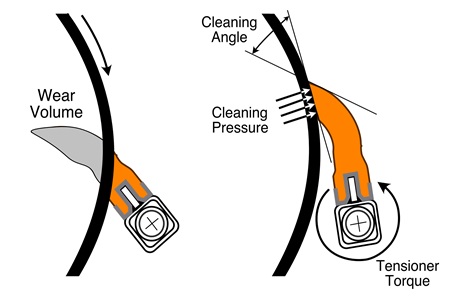

The Pit Viper is designed to achieve a higher level of productivity for the lowest cost of ownership of any urethane pre-cleaner. Manufactured with Martin's unique Constant Angle Radial Pressure (CARP) technology, its curved blade maintains consistent belt-cleaning pressure as it wears, delivering effective performance throughout its life.

Besides offering outstanding belt cleaning, the Pit Viper is designed to simplify blade replacement. It makes it possible to quickly and easily replace the blade without any specialist tools by removing and reinserting a single retaining pin – essential when abrasive materials make frequent replacement a necessity.

"We'd tried various products to keep conveyor belts clean, but as volumes increased and plants have been operating with higher throughputs, it became clear that we needed a customised approach to ensure materials were flowing through our process as efficiently as possible," said Mitchell.

"We were looking to partner with a provider that would take an open-minded approach, to work alongside us to understand the specific issues at each point in the process and help us solve the problems on an ongoing basis, rather than just sell us their products."

reinserting a single retaining pin (shown at the bottom right of the picture). Pic: Martin Engineering 2024

After performing well at the first five plants, Blue Phoenix quickly sought a national deal to install and maintain Pit Vipers throughout its national network. In addition, several of Martin's 'set-and-forget' SQC2 secondary belt cleaners were also installed following successful trials.

As more belt cleaners were installed and Martin's technicians closely monitored their performance, tailored improvements were made to further optimise belt-cleaning capacity, including fitting stainless steel parts to address corrosion issues. By 2021, almost every belt in the Blue Phoenix network - more than 200 conveyor belts in total – was being kept clean by a Martin system incorporating the blade and tensioner mounted on a mainframe.

Regular servicing of the blades and tensioners ensures constant cleaning pressure. This is done with the support of Martin's nationwide service partner, Wright Engineering, who happened to build some of Blue Phoenix's newer plants (and fitted them with Martin belt cleaners from the outset). Yet keeping the plants clean and running at their best is much more than belt cleaners and periodic servicing.

Indeed, the Blue Phoenix workforce continually monitors things on the ground: "Our plant teams are the eyes and ears of productivity, and they each have responsibility for a different work zone," said Mitchell. "Every team member takes responsibility for maintaining our high standards of housekeeping. To facilitate that, we have an extensive training programme, including virtually all of our operational employees participating in Martin Engineering's Foundations seminars for belts and belt cleaners.

"There's nothing else like Foundations in the industry, and it's been an invaluable part of the training for our teams to help them understand things like preventive maintenance. Now, they can identify potential issues – not just relating to belt cleaners, but rollers and bearings, belt condition and mistracking, and so on – and report any issues so they can be dealt with as part of scheduled maintenance before an unscheduled breakdown happens.

"As a result of our work with Martin, since 2018, we reckon we've seen an 80% reduction in spillage compared to when scrapers were not being maintained. Back then, we had people sweeping the floors almost constantly – and that's not a good use of anyone's time, let alone the skilled people we employ.

"So we've come on in leaps and bounds, but we're not sitting back; we believe there are always better ways of doing things. The belt scrapers are working really well, but what's key is that the arrangement with Martin and Wright, too, gives us confidence in the products and confidence in the people that we have to support us to maintain and continuously improve the performance of our plants. We never feel alone.

"Every challenge we've thrown at the Martin Engineering team has resulted in them coming up with a solution. Thanks to open dialogue and a partnership mindset between Martin Engineering and Blue Phoenix, a bespoke approach and a drive for continuous improvement is helping to maintain productivity in a sector that is proud to deliver circularity."