Compressors and generators are widely used in quarries, from powering hammers and drills, and to provide lighting.

While new, upgraded and more energy efficient products now being introduced by manufacturers, one quarry operator is already claiming a saving of some £4,200 (€5,400/US$6,400)/year using an intelligent system.

Longcliffe Quarries, Matlock, County Derbyshire, central England, one of the leading suppliers of calcium carbonate in the UK, says it is achieving the minimum annual energy savings with a predicted return on investment of less than 12 months after installation of a new compressed air system from Gardner Denver distributor, Aircare Compressor Services.

The company is implementing a programme to reduce its carbon and other greenhouse gas emissions, and as part of this it continually analyses the energy performance of all its plant and equipment.

It says its previous compressors had been running continually, five days/week for six years, providing air to feed the pneumatic circuits throughout the quarry. With over 45,000 running hours on each machine, it says performance and reliability were becoming problematic, impacting on both energy and maintenance costs.

In addition, the machines had been installed without any compressed air control, meaning that the two 45kW units were both running simultaneously, and therefore “inefficiently” in order to produce the target air pressure.

“Our compressors are a vital component in our plant operations and, if a machine fails it could result in costly downtime,” says Mark Whittaker, works engineer.

“Having worked with Aircare previously, we commissioned the company to conduct a comprehensive audit of our actual site air demands to ascertain whether it would be more cost-effective to refurbish our existing machines or replace them with a new compressed air system.

“The results confirmed that smaller, high efficiency compressors from CompAir would offer the low cost of ownership that we required, with payback in as little as 12 months.”

Steve Flint, account manager at Aircare, says: “Using the CompAir airINSITE air auditing system, we monitored the air demand over a typical production period to identify system inefficiencies. Results from the audit indicated that the site’s air demand could be met with two smaller 37kW units.

“The majority of the time, the minimum air demand from generation fluctuates from 150ft³-210ft³(cfm)/minute (4.25m³-5.95m³). This typically requires only one compressor, a CompAir L37RS speed-regulated unit to deliver the required air output to meet the peaks and troughs in air demand. However, during busy periods, demand from generation can peak at 410cfm (11.6m³).

Using a bespoke designed base load selector control system, the fixed-speed L37 compressor is automatically brought on line to cope with the increased air requirement until demand decreases.

“Long ago we made a deliberate strategic decision not to compete with our genpower customers. That’s the right choice for us, and always will be,” says Giorgio Paris, head of the industrial engine segment at Volvo Penta.

“By sticking to what we do best, loose engine sales, we’re still a key player on the genset free market, and we can remain the preferred choice for OEMs who don’t want to have to compete against their own suppliers.

“Some of the world’s largest genset producers will only partner with non-competing engine suppliers. Our ambition is to be a reliable business partner to our OEMs, not just a supplier. We want to maintain close relationships with our customers, throughout the life cycles of their engines,” says Paris.

“If that’s our goal, we can’t also compete against our customers.”

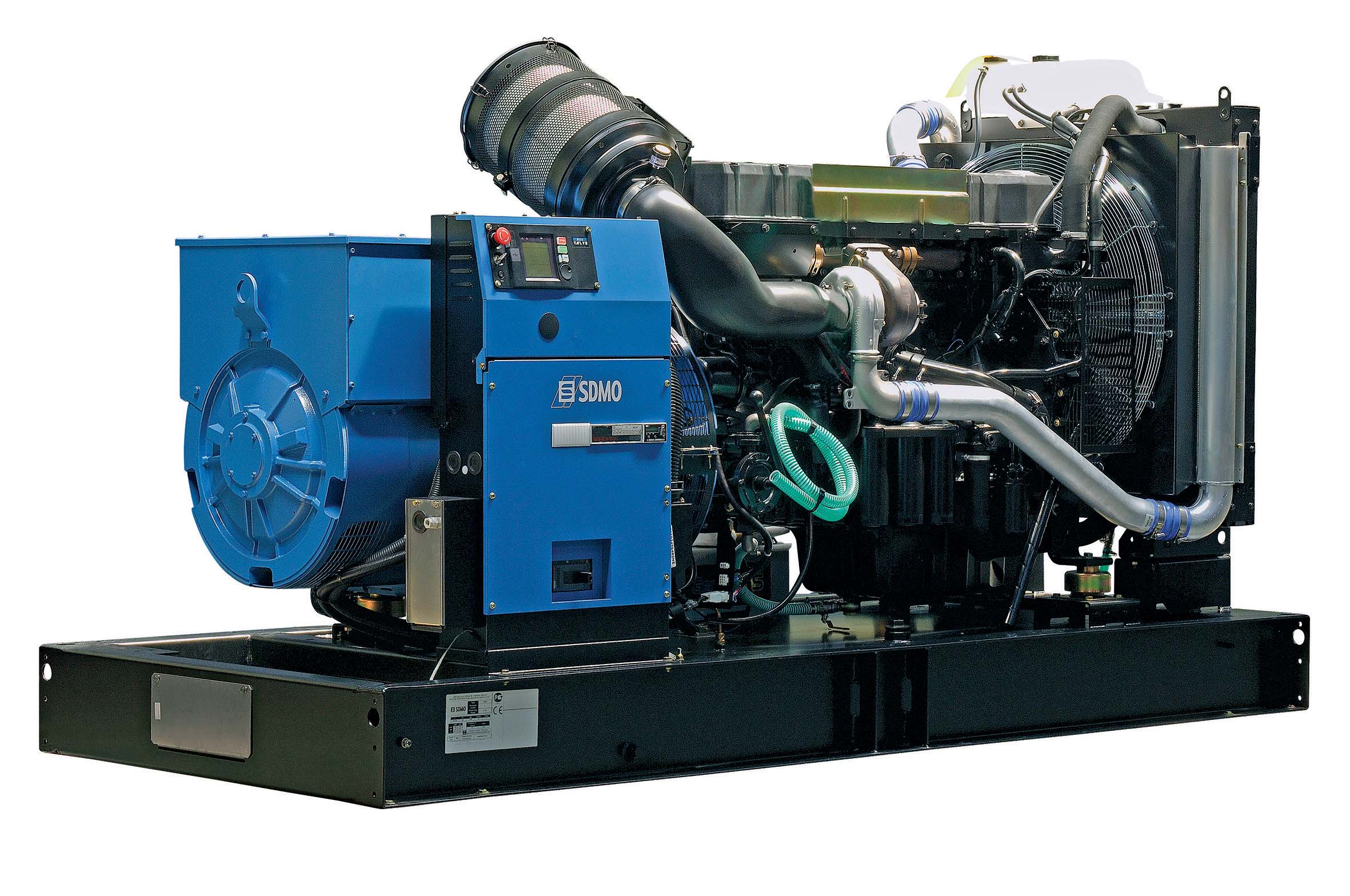

SDMO, based in Brest, France, the third largest generator set manufacturer in the world and the first “non-captive” one, produces more than 60,000 gensets each year (20,000 of them diesel industrial gensets), and is one of Volvo Penta’s largest customers for 7-16litre powergen engines.

“It’s difficult to compete on the market with an engine supplier/genset producer because they won’t pay as much for their own engines as we will,” says Philippe Forest, communication department manager at SDMO.

“They can undercut us significantly in price, and that makes it hard for us to be competitive.”

In 2014 the two companies celebrated 20 years of business together and SDMO received the 500,000th 13litre engine to roll off

“Because Volvo Penta works with the Volvo Group to produce engines, we can supply OEMs with units like the D13 that are produced in high volumes and proven through many hours of field testing and real-life use,” says Martin Skoglund, acting vice president of product management Industrial.

Meanwhile,

“As well as a wide selection of Tier 3 high ambient models, the range also includes several Tier 1 or Tier 2 engine-powered models well suited to the fuel quality levels found in these regions,” says Doosan Portable Power.

For example, for quarrying, deep drilling for oil and gas exploration, water well drilling and pipeline work as well as foundation drilling in general construction, Doosan offers a number of different models, including the XHP900W CAT-T1 and XHP1070W CAT-T1 models incorporating the CAT 3406 Tier l mechanically-controlled engine ideal for use in MEA. The XHP900W CAT-T1 and XHP1070WCAT-T1 compressors have free air deliveries of 900cfm (25.4m³/minute) and 1,070cfm (30.3m³/minute), respectively, at an output pressure of 24.1bar.

Taking the range up to a free air delivery of 1,270cfm (36 m³/min) and an output pressure of 500cfm (35bar) is the XXHP1270 model, which offers as standard dual flow and dual pressure.

With a new dual mode feature (a choice of two pressure and flow ratings on the same machine) is Doosan Portable Power’s new Stage IIIB compliant 7/125-10/110 portable compressor.

It is powered by the Stage IIIB

By pushing a button on the keypad, the operator can switch between LO (low pressure mode: rated pressure 6.9bar/free air delivery 12m³/minute) and HI (high pressure mode: rated pressure 10.3bar/free air delivery 10.6m³/minute).

The company says its generators from 80-200kVA (G80-IIIA, 80 kVA prime power to G200-IIIA, 200kVA prime power) range of generators are the first models from the company to meet the EU Stage IIIA engine emissions regulations for generators.

“The output performance stability of the generators is ensured by an optimised powertrain featuring a combination of

In another development,

Among the generators in the Pro Line is the CPPG Professional model, designed for continuous usage and available either with a petrol or diesel engine.

The generator benefits from more advanced features and additional protection to extend its life expectancy and safety, making it particularly “well suited to the rigours of the rental market.”

Alongside automatic voltage regulation, the CPPG Advanced model protects its users with an isometer protection and thermal protection circuit breaker, as well as incorporating an intuitive instrumentation panel, electric key start and a number of alarm and shutdown options.

The CPPG Advanced+ generator is enclosed and soundproofed for demanding, dusty or heavily populated locations, as well as complying with European noise regulations.

“By launching our widest ever range of portable generators, we believe we can offer the construction industry the best possible choice, depending on its budget and their requirements,” says Daniel Escuer, product marketing manager (power) for Chicago Pneumatic.

Both the Standard Line and Pro Line generators have been developed through extensive field testing.

In March, Atlas Copco says it will launch its new QIS range of industrial generators, the first models to be introduced under the Gesan line, and to meet the widest range of power needs the 50Hz QIS comes in 18 models.

The smallest is currently the QIS 65 (60kVA/48kW prime power; 66kVA/53kW standby) while the smaller QIS 10 will complete the range in March 2015. The largest is the QIS 830 (752kVA/601kW prime power; 830kVA/664kW standby). The 60Hz unit is also offered in 18 sizes, from the QIS 60 (70kVA/56kW prime power; 77kVA/62kW standby) to the QIS 740 (849kVA/679kW prime power; 925kVA/740kW standby).

“At Atlas Copco we understand the requirements of different industries, and thanks to our retrofit kits we can fulfill all these specific needs even after the QIS generator has left the factory,” says Angel Nieto, product manager