The multi-tool machine combines peeling, buffing and grooving. After several months of development and manufacturing, the machine - which will provide tyres for quarrying and mining equipment - has passed acceptance tests conducted by Renova staff at the TRM production site.

The machine is now ready to be shipped to the Renova production plant in Peru where a similar machine has been operating since 2008.

TRM says that the current machine has been completely redesigned both mechanically and in terms of automation. It adds that it is now fully compliant with Industry 4.0 requirements, including all developments in data collection and data mining.

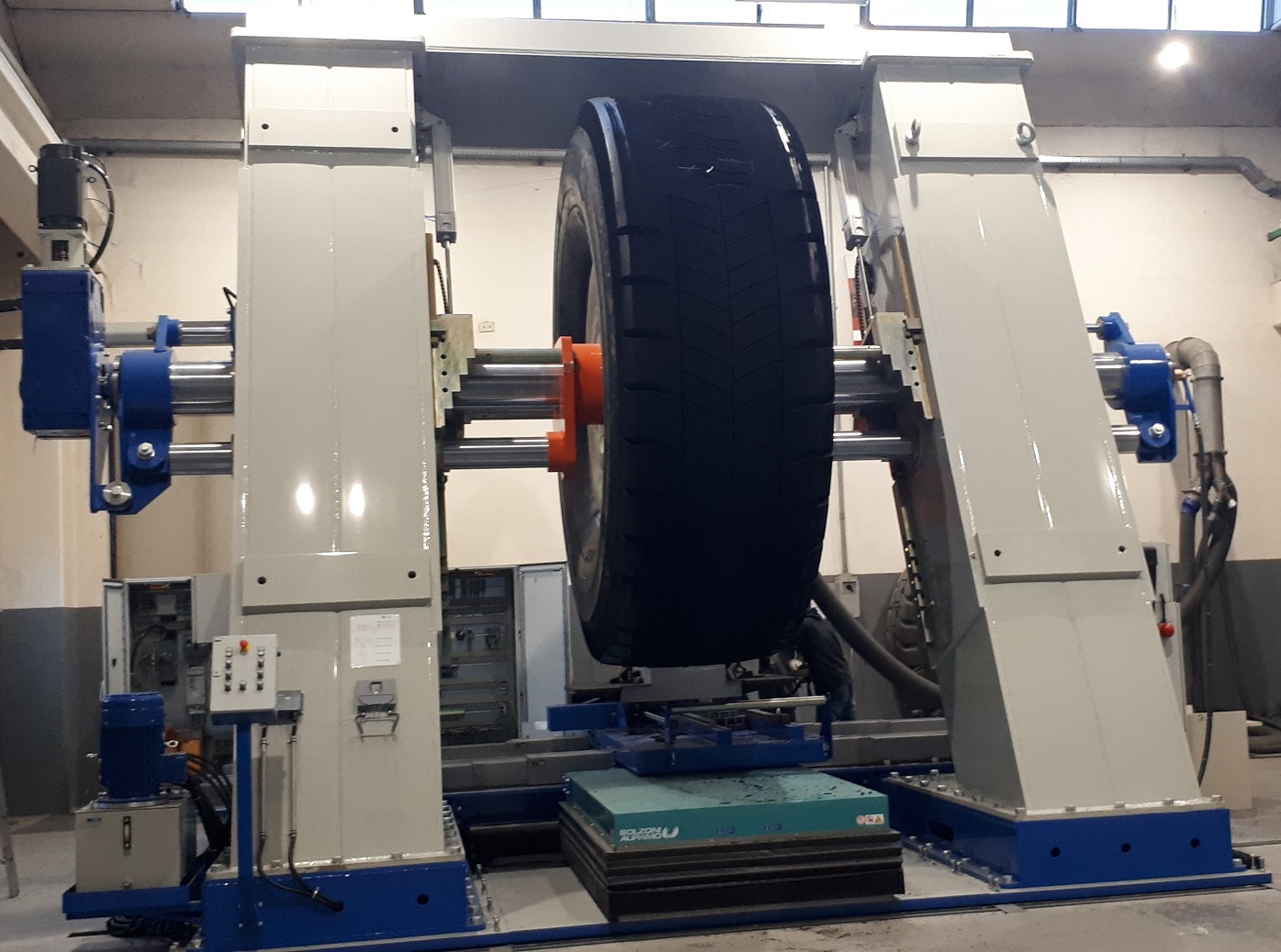

The working gantry has two monolithic double-structure columns weighing fifteen tons each, and the entire machine is over 6m in height from the ground with a total weight of 50 tonnes.

TRM – Retreading Technology - is based in the province of Trento, Italy. It specialises in the design and manufacturing of sophisticated and technologically advanced systems for retreading passenger, truck, OTR and aircraft tyres.

Renova – which corporate headquarter is at Lima, Peru. It claims to be the first retreader in the world to retread size 53/80R63 tyres (in 2006) and 59/80R63 tyres (in 2010).

In its two factories in Peru and Chile, more than 300 tyres are retreaded each month for the South American mines and quarrying market.