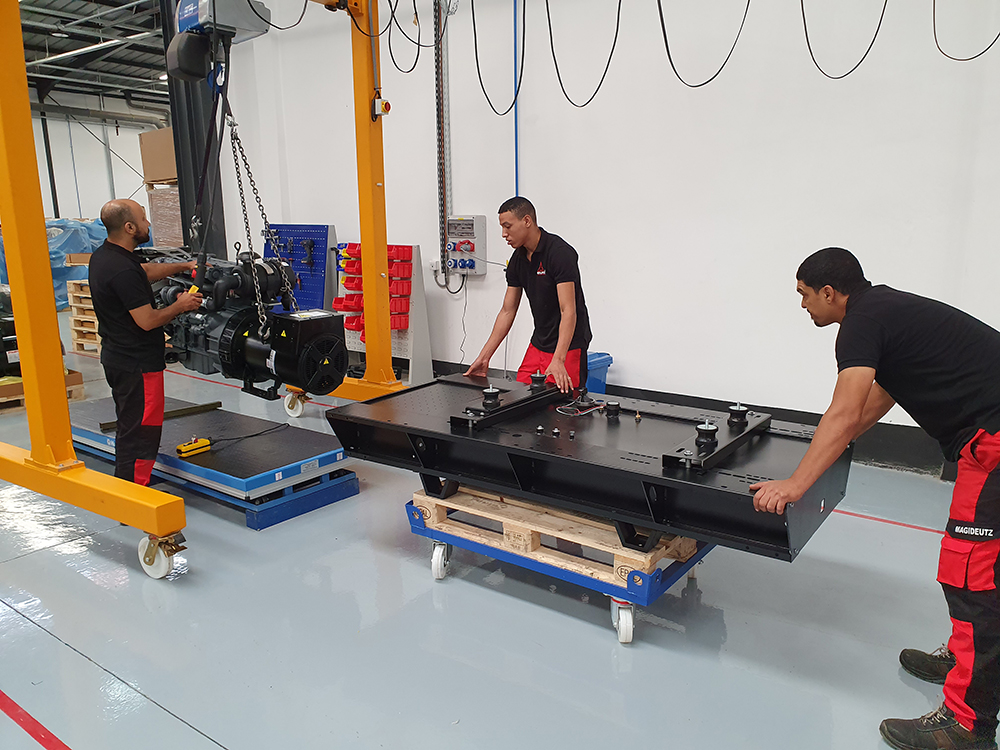

The previous manufacturing site offered only limited scope for growth and modernization due to its central location in Casablanca. The new site in Sapino is located in an industrial park close to Casablanca airport. It covers an area of 3,420m² and features state-of-the-art equipment for the manufacture of high-quality Deutz gensets. These are in high demand in the region as a source of off-grid energy.

Deutz offers both diesel and highly efficient hybrid variants, either battery-driven or powered by a solar module. The concept is that if the engine generates more electricity than needed, any excess energy is stored in the battery. If required, this energy can then either boost the engine or even act as the sole power supply source, resulting in fuel savings of up to 65%. If the diesel engine fails, the battery is also able to keep the genset operational for up to 24 hours. The solar hybrid variant has a solar collector which, in particularly sunny parts of the world, is capable of providing most of the power needed by itself. The diesel engine starts up occasionally, providing additional support at power consumption peaks or on days when the sun does not shine. This allows extremely efficient operation as regards fuel consumption and maintenance, plus a long service life.

Bernd Breves, general manager of Magideutz, explains: “We will now have a target capacity of 3,000 units a year compared to 1,000 units currently. This will allow us to supply our local customers with our tried and tested products even more quickly. What’s more, our local employees now have access to fully upgraded manufacturing equipment.