The company says the main factors causing the shortage have been a huge increase in demand across the UK cement market, cement plant shutdowns during the COVID-19 pandemic, and shortages in the availability of both haulage and packaging/pallets.

Hanson had already implemented a packed cement allocation in early May 2021 and calculated the number of daily loads per customer based on the production and distribution levels that it believed were achievable. Its own concrete business has been subject to the same allocation. Packed products director Andrew Simpson said that regrettably the company has been unable to maintain those levels, so the company has had to take the decision to reduce the allocation from 17 May 2021.

"We will closely monitor these levels in line with our capabilities, and release the restrictions as soon as possible," he added.

Simpson says that Hanson is looking to increase capacity by importing cement, although this is difficult as the increase in demand is global and there is reduced availability of shipping.

"We are making decisions daily on the right product mix to produce to be able to maximise supply," he added.

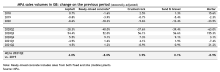

Hanson says that the cement market has seen an increase of around 30% across all sectors since mid-2020, and that this is unprecedented as the market normally fluctuates with high levels of activity in one sector being counterbalanced by lower levels in others.

The bulk cement market consumes roughly 80% of total cement production and Hanson Cement has an even split between bulk and packed cement. The main sectors for cement usage are ready-mixed concrete, concrete product manufacture, construction site activity and builders’ merchants.

Commenting on its cement production, the company says it is essential that its maintain its cement plants to remove the risk of critical failures, which would have a major impact on the whole UK construction industry. "Our 2021 shut-down resulted in some unforeseen work being needed, whilst stock levels were lower than normal due to demand," it added. "Other manufacturers also performed shut-downs on their plants, with some delayed by Covid restrictions."

Hanson says it competes for haulage with FMCG and other sectors, all of whom have seen increases in demand, and this has resulted in a shortage of vehicles available to make its deliveries. "Some areas of the country are becoming increasingly difficult to serve," it comments.

In the longer-term the company says it also faces issues on the availability of packaging (paper and plastic) due to global demand. It has been notified by its suppliers that they could have difficulties sourcing polymers and kraft paper to manufacture cement bags.

Hanson adds that pallet availability is also a concern, given the increase in demand across all timber markets affecting availability and pricing.