A study by Nottingham Trent University (NTU) shows that waste foundry sand – a by-product of the metal casting industry - could be used to make concrete suitable for withstanding lighter loads.

Led by Professor Amin Al-Habaibeh, an expert in intelligent engineering systems, the research shows that with a substitution ratio of up to 30 per cent, recycled waste foundry sand-based concrete has a compression strength of up to 78 per cent of normal concrete.

This makes it strong enough for concrete products such as curb stones, garden slabs, cycling pavements, and lighter load-bearing concrete products.

Professor Al-Habaibeh, of the School of Architecture, Design and the Built Environment, said: “The results suggest that waste foundry sand can be used in the production of concrete products when a reduction in strength is not critical.

“This is good news for the environment, as it shows that the use of natural sand can be reduced, and therefore, so can the need for sending waste foundry sand to landfill.

“By using waste foundry sand, the overall cost of concrete can be cut, and CO2 emissions can be reduced during transportation also.”

Concrete is one of the fundamental materials in the construction industry. Typically, it is composed of sand, cement, aggregate and water.

Foundries purchase siliceous sands to create moulds that give shape to the melted metals they are casting. But these sands become waste after several uses and must be properly recovered or disposed of. Any improper disposal of waste foundry sand can cause environmental issues.

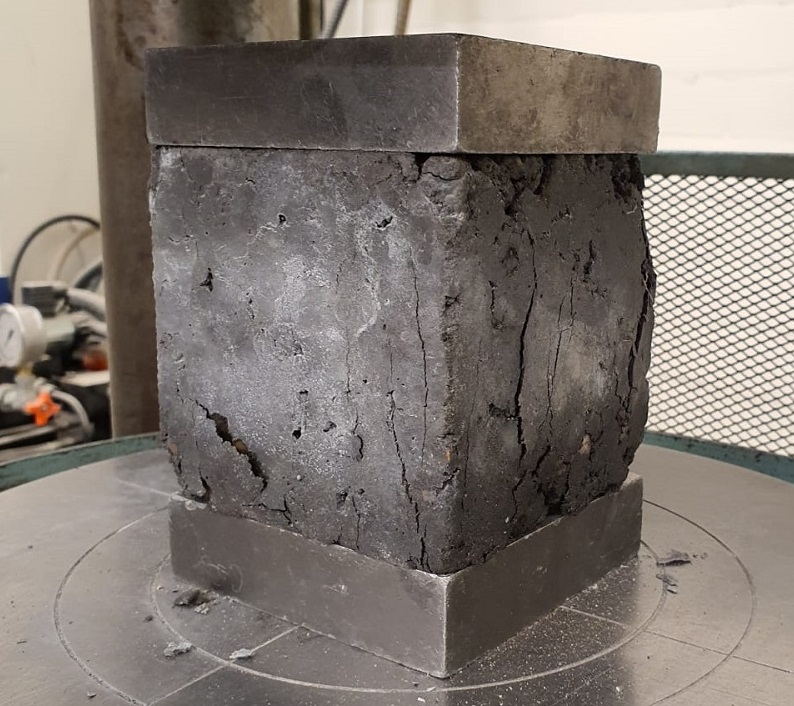

The research by NTU shows that concrete made with waste foundry sand has a compression strength of around 23 newtons per square millimetre (N/mm2).

PhD candidate Sirwan Faraj, a researcher in the School of Architecture, Design and the Built Environment at NTU, said: “In many sectors, recycling waste foundry sand, instead of using virgin materials, can result in a slight decrease in the technical performances of the final products.

“But this reduction could still be perfectly acceptable for a range of concrete products, depending on the needed application. It could be used effectively as a partial or complete replacement of standard sand in suitable quality mortars and concretes.”