Quality screening media on an aggregates production plant offers big uptime and productivity gains for quarry operators. Guy Woodford, editor of our sister title Aggregates Business, talks to one leading global manufacturer’s expert on the topic, and reports on two of another manufacturer’s latest screening media solutions.

Metso is a major player when it comes to state-of-the-art screening media for aggregates processing applications. The Finland-headquartered, global market manufacturer has one of the widest offerings in this business, offering the right screening media product for almost every application.

Claes Larsson, director, Screening Media Products, Metso, spoke to Aggregates Business about some of the most common customer challenges related to aggregates screening today.

“The most typical challenges for stationary plants are related to preventive maintenance and accurate follow-up on wear life of individual components, i.e. making sure every piece of equipment is protected properly for continuous operation. Another issue is health and safety during maintenance: how to minimise interventions to change wear parts and other components. In addition to these, making a variety of sometimes challenging end products according to tight regional specifications for aggregates can be challenging. Difficult process conditions like blinding and pegging may reduce output.

“For mobile and portable equipment, quick changes of screening media are crucial to meet varying tasks and contractual commitments. These require fast service and prompt deliveries from the screening media supplier.”

Larsson says the main driver for using synthetic screening media is to reduce time-consuming work related to change-outs, such as wire cloth. “The cost of this labour is important, but even more is the operational time lost when changing media. If screens in the plant are bottlenecks limiting the output, then quick pay-back can be achieved with the use of synthetic screening media.

“Other cases consist of those when customers are experiencing ‘non-performance’, meaning that the screen cannot perform with the existing screening media solution. The problems are often related to blinding of screen surfaces and pegging of rocks in apertures. Changing media will then help and make the unit productive once again.

“Other reasons could be purely health and safety-related. For example, rubber or polyurethane lower noise emissions compared to steel wire or perforated plate. Also, less maintenance needed on the unit equals fewer operator interventions and less risk of injuries. Also, with modular synthetic decks, lifting weights are typically lower when compared to standard steel wire solutions.”

Larsson says poor performance of the screening media can also affect other equipment such as crushers. Blinding and pegging can result in carry-over of fines into the crushing chamber, resulting in process or wear-related issues.

Highlighting how Metso can solve these challenges, Larsson says: “Metso has been working with screening media solutions for decades and is a pioneer in the development of synthetic screening media. Today, we have a comprehensive range of screening media products and accessories and can select the best solution for almost any customer application.”

Larsson stresses how Metso’s portfolio of polyurethane and rubber screening media products covers applications from heavy primary screening to dewatering, including wire and tension synthetic solutions, as well as modular systems and panels.

He continues: “Metso has screening media solutions to prevent blinding and pegging by using more flexible materials. The Screen Planner software allows you to control and maintain the history and operation of the screens. We also have tools that enable the calculation and identification of hidden added value when planning to change to an optimal screening media solution.”

Larsson says Metso’s recently launched hammerless attachment solution eliminates the use of sledge hammers and crowbars, as the pins are screwed into place and removed by using an impact driver, taking only seconds. This method is safer and is said by Larsson to require less operator force and strain compared to traditional pin and sleeve systems, easing work in confined spaces. Larsson notes that a dramatic decrease in shutdown duration increases the uptime of the screening process and makes a difference in productivity, in addition to improving safety.

During 2019, Larsson says Metso will migrate from “old-style” gravity casting of polyurethane to injection moulding. “This will result in advantages including better availability and better accuracy of openings, leading to more exact production of aggregates. The products will also allow for a higher open area.”

Haver & Boecker, a leading equipment manufacturer and solutions provider in mining and aggregates applications, has developed Ty-Dura rubber screen media for large tonnages, large top sizes and abrasive material. It is said to work well with crushed dry aggregates and high-tonnage wet applications, such as scrubber or mill discharge, while also being exceptionally durable and offering effective noise reduction.

Ty-Dura was highlighted by Haver & Boecker at the 2019 AGG1 Academy & Expo (12-14 February) in Indianapolis, USA.

“Our Ty-Dura screen media stands up well to the most unforgiving applications,” said Karen Thompson, Haver & Boecker Canada president. “With its high durability and longevity, producers will often be able to spend less time changing worn-out screen media and more time increasing their bottom line.”

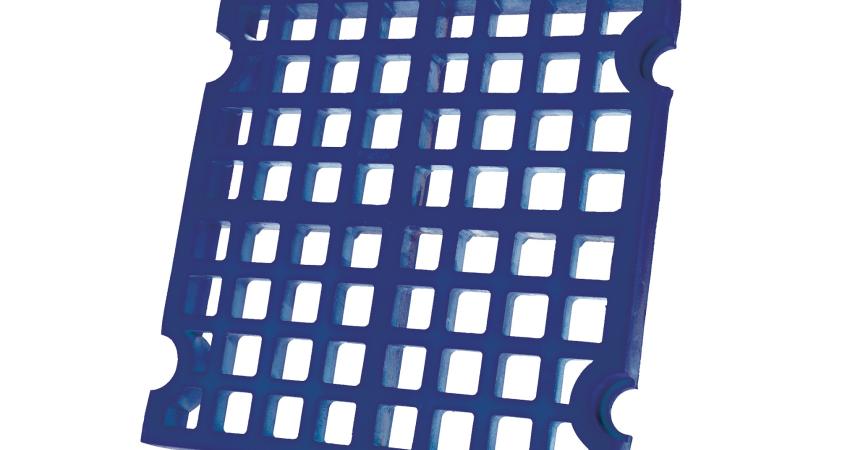

Ty-Dura is manufactured in both side-tensioned and modular configurations, and is available in square, round, slotted or specialty opening designs that are all tapered to resist or eliminate pegging.

The side-tensioned hooked sections feature a custom-formulated, compression-moulded natural rubber, supported by a stainless steel cable substructure allowing for easy tensioning and preventing the stretching often experienced with other types of rubber screen media.

Ty-Dura’s hooked sections also eliminate the need for a deck conversion when switching from woven wire. Retrofitting a machine from a cambered deck to a flat deck can cost as much as US$15,000 per deck. The hooked sections can be used on the cambered deck to eliminate the need for that conversion. This also allows operators to test the media on a vibrating screen with no additional conversion cost or changes to the machine.

Ty-Dura modular panels are available in pin and sleeve, snap, groove and bolt-down options.

It is said to be a great option for top sizes larger than 15cm and high tonnages. The rubber — up to 10cm thick — also resists abrasive material. Its openings are tapered to prevent blinding and pegging. Ty-Dura is also ideal for applications where sound is an issue, as the rubber dramatically reduces noise.

Because it handles impact so well, Ty-Dura is highly effective on a vibrating screen’s feed end or in the second position.

Ty-Dura is ideal for all types of vibrating screens except for high-frequency fine screening units.

Haver & Boecker also offers its Tyler brand of hooked engineered screen media, including the Ty-Max and Ty-Wire products, as another solution to the problem of expensive deck conversions.

Tyler engineered screen media was due to be showcased by Haver & Boecker at bauma 2019 in Munich, Germany (8-14 April).

Ty-Max and Ty-Wire can be blended with woven wire or self-cleaning screens on cambered decks. In many applications, operators are looking for more wear life on the feed end of the screen. This can be accomplished by installing a section of Ty-Max at the feed end. Ty-Wire can be used in the middle of the deck, for example, where basic screening takes place to give operators the ideal combination of wear life and open area. Using woven wire or self-cleaning screens at the discharge end will provide maximum open area at the end of the deck.

The screen media is manufactured out of Haver & Boecker’s signature blend of polyurethane. It’s made in one of the only facilities that blends its own material, which is critical for quality control. Chemists developed the media to offer the best combination of open area and wear life for both wet and dry applications. Engineered screen media is poured open cast, resulting in a claimed 1.5 to 2 times longer wear life than injection-moulded products sold at comparable prices. In addition, open-cast polyurethane permanently hardens when cured to maintain its chemical properties, so it resists wear and tear.