Increasingly, the challenge for quarries, surface mines and aggregate excavations is gaining access to the rock to produce materials as quickly, accurately and cost-effectively as possible. It is essential that returns are maximised and the reserve deposits are utilised as efficiently as possible. Through automating the drill and blast process, companies are able to significantly reduce costs by improving performance and increasing consistency while simultaneously enhancing rig (and therefore operator) safety. Autonomous drilling technology thus enables operations to be more efficient, achieving the goals of operational cost reduction, improved productivity and zero harm. Developed systems are customer-configurable, enabling the drill rig’s surface equipment to be controlled in response to data which is prioritised and distributed to appropriate applications as it enters the rig control system.

Automation and remote working enable drillers to remove people from the blasting and drilling locale, maximising operational safety as well as protecting operators from sound and airborne emissions. Furthermore, efficiency and productivity are enhanced as there is no need to stop drilling for breaks and shift changes. Without having operators on board, the drilling solution can operate through shift changes, lunch breaks and some blasts which increases drill rig utilisation providing greater consistency and accuracy over a long shift.

Operational benefits

By using digital drill plans and navigation, manual drill-hole marking is eliminated which results in improved accuracy and time savings, with the data collected during drilling being used to monitor system behaviour in various rock conditions and to evaluate plan execution. In the long term, autonomous drilling also delivers reduced downtime and increased rig availability due to less damage to the drill and the tooling used. The automated software ensures that the rig is used within its designed operating parameters which minimises stresses on equipment, with reduced wear and tear on equipment through automated functionality resulting in lower maintenance costs.

As autonomous drill rigs work within the standards established by the manufacturer, longer consumable life is ensured whilst at the same time delivering less unplanned maintenance. As a result, operations can progress more rapidly and improve fragmentation when coupled with an effective blasting programme, delivering lower component costs from reduced machine maintenance repairs.

The benefits translate across the entire mineral excavation value chain with the enhanced blasting and improved fragmentation from autonomous drilling causing less damage on load and haul equipment, which saves maintenance costs for the entire operations fleet. There are also benefits for operations using crushers due to the better fragmentation, a faster feed of the crusher and less energy required to process the material. This latter point highlights that autonomous drilling also has a positive environmental impact through ensuring that the equipment is consistently operated within specifications, resulting in the amount of energy and fuel burned being reduced, producing a more efficient drilling operation.

Operational benefits often extend to the workforce, as a single worker can operate multiple drill rigs, providing better organisational utilisation of skilled operators. Autonomous drilling reduces the operator to machine contact, making operations safer, with staff (and their expertise) being used more in maintenance of the technical and mechanical systems, solution monitoring and change and process management.

Appropriate system

Generally, drilling automation and the use of drilling IT systems are ideal for almost all quarrying and aggregate-excavation processes that rely on drill and blast in some form. Different levels of autonomy and integration can be achieved depending on requirements, type of application and the IT strategy of the company. However, some operations face many challenges when attempting to progress towards full drilling-fleet automation. One of the biggest is the operation’s readiness for autonomous because this isn’t a feature that comes with a ‘flip of a switch’. Change management processes must be considered and implemented to assist in transitioning an operation from a manual operation to a fully autonomous operation, with the most important information being that which the drill rig collects about the holes drilled.

In effect, a challenging factor for adopting automated drilling is the ability to manage change. The resulting process changes, with the additional layers of safety that come through the use of automated technology, necessitate a cultural transition with the operator working outside the cab rather than inside, which requires additional personnel training as well as a cultural shift. This means that when it comes to choosing the right automated drilling system, it is important to choose the system that best suits the requirements of the organisation itself. Fortunately, there are now many systems available designed to cater to the requirements of companies large and small, with some of the latest developments set to further aid automated drill and blast.

Caterpillar

Cat has placed increasing emphasis on developing systems for delivering accurate drilling and blasting to ensure a safer and more productive work environment, whilst aiming to reduce even minor deviations from the drilling pattern for more efficient and productive drilling. The company states that with higher precision and more accurate depth tracking, autonomous drills can work far more accurately to plan. That means more accurate blasting and less time spent removing overburden, resulting in higher productivity.

The newest generation of Cat drills offers all of the benefits of autonomy, starting with the release of the MD6250 and now continued with the MD6200. These come with a number of standard automated functions that help an operator drill more accurately, with simple controls and touchscreen monitors that allow for easy operation. With the addition of Cat Command for drilling, the drill rigs are capable of drilling in autonomous mode with the operator seated at a remote station designed to mimic the drill’s cab. From here, the operator is able to control up to three drills at the same time, programming them to drill single rows autonomously.

Cat Command for drilling ensures that every hole is accurately placed, drilled to the proper depth and angle, and able to stand up until blasting, with a range of capabilities that enables the operator to configure and automate the drilling system based on budget and needs. Semi-autonomous single row drilling automates the entire drilling cycle for one row, including autonomous tramming. Autonomous pattern drilling automates drill cycles and tramming for the entire blast pattern and allows one operator to manage drill operations across the site from a remote operator station.

Epiroc

Epiroc’s recently launched TeleREMOTE system is designed to control its SmartROC DTH drill rigs, MK I (based on RCS 4 platform) from a remote location. It enables the operator to access and run multiple rigs from a control centre located away from the blasting area by connecting it to a WLAN network. One of the biggest benefits of the system is its ability to effectively increase the number of productive hours in a day, reducing operator transports and idle time due to shift changes. Remote drilling, together with Epiroc’s AutoDrill and Auto-Rod Handling System features, boosts productivity as the drill rigs can work almost continuously without breaks. The safety aspect is also a major benefit as the operator can run the rig remotely due to its on-board systems.

The operator uses the Hole Navigation System for accurate positioning and a geofence function ensures that the rig stays within the predefined area. The remote rigs are also fitted with multiple cameras which provide the operator with a 360° view all around the machine. Office TeleREMOTE also includes a server rack with Automation Common Machine Server (ACMS), a video system and a safety system capable of handling one remote drill rig, with an option to be extended up to nine drill rigs, in increments of one, if required. Features such as automatic levelling and drill-stop protection are also integrated to maintain precision and safety.

Connectivity and automation have been developed by Epiroc to increase equipment productivity as well as deliver operator benefits through the integration of smart connected machines, programmed to complete a precise drilling sequence. Machine sensors alert the control room if there is an obstacle or the intervention of an operator is required. Without the normal constraints of staff schedules, this allows for extended machine uptime, reducing the wear and tear associated with a manual operation.

Komatsu

Komatsu’s drill automation technology is made up of several key building blocks: an automation controller; situational awareness technologies (cameras, LiDAR and radar); and a GPS receiver. Algorithms convert the information from the hardware to identify the machine state and execute the appropriate autonomous task. The company offers several levels of drill automation, with the most basic being passive automation which provides on-board blast-hole pattern mapping, additional camera views and uses LiDAR and radar to notify the operator of objects around the drill.

The operator-assist level of automation is effectively an autopilot function. The system executes drilling, levelling and tramming tasks, while the on-board operator manages any exceptions that may occur. The full autonomous level removes the operator from the machine and from most machine operations, only stepping in to remotely manage exceptions. Furthermore, the same information required to autonomously operate a drill can also be leveraged to identify strata to better optimise hole loading and pattern design.

Sandvik

In efforts to continuously improve and automatise its drilling equipment, Sandvik has developed what it terms as ‘full-cycle one-hole drilling automatics’. This enables the drilling of one hole automatically to a specified depth without having to manually interfere in the process. After positioning the feed to the desired hole location and inclination, the operator can select automatic drilling simply by pressing a button on top of the drilling joystick. The rig will drill and add rods/pipes automatically until the selected hole depth is reached.

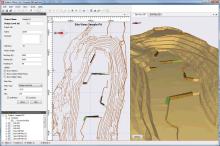

Automatic drilling ensures continuous high productivity, with less room for human error in the process, with the operator being able to perform other tasks or have a short break when using automatic drilling. Complemented with Sandvik’s TIM3D drill navigation system and automatic feed alignment option, this enables Ranger DXi series rigs to perform autonomous movements for the superstructure and position automatically with only a push of another button. Full-cycle automatic drilling options are available for Sandvik’s Pantera DPi and Ranger DXi series of top hammer drills rigs as well as the Leopard DI650i down-the-hole rig.

Further boosting Sandvik’s offering in automation is its free app, SanRemo Mobile, which makes it easier to connect to a drill rig for transferring drill plans, reports and other fleet management and drilling data in a timely and cost-effective manner. SanRemo Mobile further improves the connectivity of surface drill rigs by allowing mobile devices to be used for data transfer. This eliminates the dependence on USB drives or network coverage at worksites. Reports and MWD (measurement while drilling) data from the Sandvik TIM3D drill navigation system can be uploaded via the SanRemo Mobile app for sharing or storing. The data can be examined using, for example, Sandvik Driller’s Office or other compatible design software. Additionally, production reports from the drill rig are automatically uploaded into the My Sandvik fleet management portal.