Five years after starting manufacturing at its Monkstown facility in north Belfast, CDE continues investing in the key company site, attracting new skilled employees and increasing product output. Guy Woodford went to have a first-hand look.

The first thing that strikes you as you drive off the Belfast suburban road into CDE Monkstown is its size. The 330,000ft² former Caterpillar and FG Wilson site was acquired by CDE in 2018, with the company adding the fabrication and painting equipment it needed to support its manufacturing operations. The first CDE customer plant came out of the factory the following year.

Today, CDE Manufacturing (comprising CDE's Cookstown and Monkstown factories) has more than 200 employees, and the company plans to grow the headcount as part of its impressive global growth strategy.

My tour of the facility in late September 2024 was led by the highly personable and knowledgeable Andrew Dunbar, head of CDE factory operations.

"The factory is split into two-thirds and a third. One-third is for dry assembly. We build the machines fully, test them, and then break them down to fit into their transport modules. It gives us the satisfaction of knowing whenever the plant gets to the site, it can be efficiently installed and quickly up and running. We cut and fabricate steel all under one roof. The only outside operation is galvanising [the process of applying a protective zinc coating to steel to prevent rusting]. We try to minimise the need for galvanising. We use it on products like the Infinity screens. The company who does that for us is only ten minutes away. It's a daily milk run."

Among CDE's extensive plant range from the Monkstown factory is the CDE ProPress high-performance filter press, which was unveiled at the June 2024 edition of Hillhead.

Designed to meet the evolving needs of the construction and demolition (C&D) waste recycling, quarrying, and mining sectors, the ProPress integrates the latest technological advancements to deliver exceptional operational efficiency and maximum water recovery.

The ProPress features patent-pending technology and benefits from a flexible design and variable throughput that can be scaled to fit the processing volume of any operation.

Unlike traditional filter presses, the system is dual feed, meaning sludge is fed from both sides of the ProPress for improved efficiency and faster cycle times. Optimised sludge feed pressure also allows for faster dewatering to increase overall throughput. This is further supported by an overhead beam design that ensures reliability by reducing stress on the unit and improving its durability.

The ProPress features plates that are 25% larger (2.5m x 2m). The greater chamber volume and fewer plates overall provide maximum capacity on a smaller footprint and improve mechanical cycle times.

With the CDE ProPress, owners and operators can recycle up to 95% of process water for immediate reuse in their wash plant while simultaneously cutting waste disposal fees by recovering a filter cake product that can be used for pipe bedding and landfill capping. This eliminates the need for settling ponds, which typically require extensive maintenance, consume labour resources, and incur significant costs.

"Alongside the ProPress, the AggMax, EvoWash, and M-Series [sand & aggregates washing] plant can all come out of Monkstown. The only product we don't manufacture or assemble here is the AquaCycle thickener due to its sheer size," says Dunbar.

"The big thing we're trying to drive through all our factories is material flow and consistency. For example, we say, 'Monkstown, you focus on assembly and these products. Cookstown [factory at CDE global HQ], you focus on these other products.' We are going on an intensive continuous improvement journey and developing the mindset to support that. For instance, rather than having X employee working on an AggMax one day and an EvoWash the next, let's keep you on the EvoWash and get you really good at efficiently assembling it. This has helped reduce our order lead times to 22 weeks from up to 38 weeks two or three years ago. In terms of assembly, we've doubled our output without doubling our footprint."

As you step onto the factory floor, a large wall display tells the story of the company's impressive growth since Tony Convery founded it in 1992. Today, CDE operates across five strategic markets, with dedicated teams in each market on hand to deliver proven solutions and aftersales support for customers.

"Our company story is a good reminder to ourselves how far we've come. I joined CDE in 2013 and was involved in this Qatar project," says Dunbar, pointing at a picture and accompanying words. "That was at the start of the after-sales side of things I was involved with. The display also shows everyone working here how the value they add through their work impacts globally. It's saying, 'This machine here will take oil out of sand and have a huge positive effect on the lives of people living in the neighbouring community.'

"We'll also be putting up each of our manufacturing team's storyboards, charting their continuous improvement project achievements. Anyone walking past will see that journey that we're on."

Asked about the extent to which the manufacturing leadership team encourages staff feedback and engagement in the day-to-day running of the site, he adds: "From a management and supervisor perspective, we try to promote that we're all visible and energetic leaders. I have responsibility for the whole factory, and I'm not the sort of person that sits behind a desk. I don't want my production managers and supervisors doing that either. We have employee forums, and then there are health and safety and quality meetings, which involve the shop floor. A Teams call or message might work in an office environment but not in a factory setting."

We pass a section of the factory floor where many smaller shop order parts are neatly placed, each accompanied by checklists. Dunbar explains: "The checklists allow the team to check how many elements are needed for each part, so they can see if any are missing. The colour-coding system indicate whether they relate to the current or the previous week's [plant assembly] work. If it's pink, grab it. If not, wait for further instructions. It is a simple visual indicator to help the team prioritise their work. It was Tony Convery's idea! We can have 200-300 shop orders at any given time, so the colour-coding really helps. The information is fed into our ERP [enterprise resource planning] system, which we call the dynamic order process [DOP].

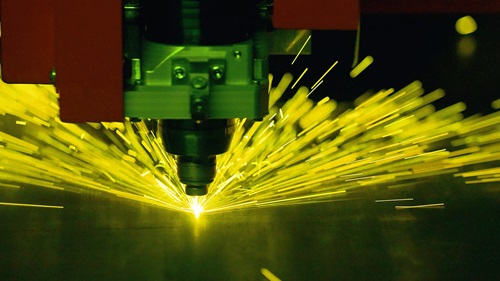

"Regarding steel sheet cutting, we have laser and plasma cutting machines. We try to prioritise the lasers – although the plasma cutting machine is used for the ProPress, which needs thicker steel sheets. We have two fairly new 4-metre by 5-metre lasers. They were a significant investment and came with an automatic feeding system. All the machines are dual bed: one for cutting, the other for waiting. The laser cutters give a nice, clean cut. The cutting side of the factory focuses on sheet utilisation. We put together a week's worth of cutting using as minimal steel sheets as possible. The rest of the factory works on shop orders, which is very customer-specific."

The factory also has four sheet metal folding machines: two five-metre and two that can hold up to six metres and be changed into a single 12-metre press. "We don't have anything bigger than 12 metres, so that gives us full in-house folding capability," explains Dunbar.

He outlines how the factory embraces sustainability: "Putting in laser steel cutting has been good for reducing emissions. We also harvest rainwater and recycle what we have. We are quite early on the sustainability journey, as manufacturing facilities tend to be energy-intensive. Given our shift patterns, we only need to run the paint line and laser steel-cutting machines for three days rather than five. This reduces our energy usage. We separate our steel into painted and raw. We have a local dealer to recycle any raw steel going for scrap"

Touching on the CDE work culture, Dunbar continues: "Every day is different here, and we are always looking for people who will roll their sleeves up and get on with the job. Within CDE, we have a FLEX department. They are a team of multi-skilled engineers who can provide valuable support and reduce some of the burden from the team at this and other sites."

A proud father, Dunbar says his two young daughters are showing engineering promise in their home woodwork with Dad. He refers to the "sense of purpose" he finds in his career at CDE. "You get a double whack – purpose from the company's growth and what the customer's plant can do for them. For example, we've got a big project to treat oil-contaminated soil in the Middle East. It will play a part in vital clean-up work in that area." Giving a sporting purpose example, Dunbar says one of CDE's M4500s in America is also producing specific sand for the PGA golf tour.

"It's about building our best world a ton at a time," says Sarah Corr, CDE's head of marketing, accompanying Andrew and I on the tour. "We break that statement down into what it means to our customers, communities, supply chain and us."

Dunbar continues: "We had customers here recently, and they have just finished the same journey we are going on around factory air quality and extraction. Around two years ago, the HSE [Health & Safety Executive] released a directive that anyone doing welding had to provide clean air and take the weld fumes out of the air. Our welders have always used air-fed masks. They get clean air, but new research meant that all organisations that have welding as part of their process need to add additional engineering controls to manage the fumes rising from the welding activity. We have always been quite a clean factory due to the high volume of air ventilation, but the new HSE directive meant we needed to introduce a LEV [local exhaust ventilation] system at all our weld areas. We worked with local companies who had started this journey as well as the HSE themselves to ensure we found the best solution. It led to a nearly £200,000 investment to meet the legislation, and continue to protect our team and drive our "Home Safe Every Day" culture."

After showing me the powder line, the manual and automated paint areas, and the larger parts processing section, which includes sumps [tanks that collect water and fine material used in the washing process before the water is pumped to a cyclone stage for sand cleaning and separation], Dunbar says: "These are examples of how we look to improve the flow of manufacturing and assembly. When we came here, we knew that if we cracked flow, we cracked the optimum working of the factory."

We reach the conveyor assembly section of the site, and Dunbar picks up a part. "This is part 91 of the conveyor kit. A bottleneck in our production can be conveyor assembly. If we send something incomplete here, we lose a lot of time. To prevent this, the people working on paint have a checklist. Once they cross-reference it with the DOP system to check that a 15-metre conveyor, for example, has all its near 300 parts, it can go through to conveyor assembly."

As we take in the Infinity screen assembly area, Dunbar highlights the the company’s’s strong health and safety focus: "We have a site supervisor on every shift, and their training includes first aid, mental health first aid, and fire warden."

"Mental health first aiders have become a big part of CDE's focus on holistic well-being of the workforce . I think we're up to 20 now," adds Corr.

Dunbar stresses each completed wash plant's intensive testing schedule. This follows its in-process validation (IPV) during its manufacturing and assembly. "We have people who come and see if the plant is where it should be at that stage. If fabrication were doing an IPV, they may find a sump that isn't right and correct it before it goes to welding. We also have pre-delivery inspections [PDIs] to ensure the finished plant is as per the customer specification."

We end our tour in the outside yard, where we look at some of the finished CDE wash plants awaiting customer dispatch. "I first came here in March 2019, and stores were unlike now," remembers Corr. "This site is enormous, and we have grown into it. I remember four EvoWash plants placed in a line and an enormous AggMax fully built up before shipping to Calgary [Canada]. Every time I come down, something has evolved and changed, which is brilliant. It shows CDE's commitment to continuous improvement, efficiency and sustainable manufacturing."