Turkey’s recent building boom has led to growing demand for cement, and manufacturers in the country are modernising their cement production methods.

One of these is Göltas Cemento, located close to Isparta in western Turkey, approximately 130 kilometres north of Antalya. The company opted for modernising its kiln and increasing the performance. An increase from 250 to 400 tonnes per hour of the conveying-technology capacity was required, for a chain apron conveyor that transports the clinker from the kiln-cooling system to the silo.

To achieve more economical production, Göltas Cemento has been increasingly opting for alternative fuels in recent years, which meant that the content of fines particles also increased continuously. The existing conveyor already transported high quantities of material, and the process had become extremely dirty, with personnel constantly needed to perform cleaning work.

To find an efficient solution Göltas Cement turned to its long-standing partner, system provider Beumer Group. German-headquartered Beumer has supplied two clinker transport systems and four belt bucket elevators over the course of their existing partnership. The project phase began mid-2015 and the contract was awarded in the beginning of 2016, followed by the installation and commissioning in the autumn of that year.

“For a more powerful chain apron conveyor, we would have needed to take down the entire system including the building structures and the concrete tunnel,” said André Tissen, sales manager for customer support at Beumer Group, who was responsible for the project with his team. “This wasn’t necessary when opting for the belt version. It reaches double the conveying speed, so that the Beumer Group engineers could design the system for an increased capacity while keeping the same width. The conveyor bridge and the self-supporting steel structure, as well as the concrete foundations remained.”

According to Tissen, Göltas Cement was able to considerably reduce costs and put the system quickly into operation.

“The silo is 50m high. In order to overcome an inclination of 40 degrees, we installed a steel box conveyor,” he said, adding that it releases almost no material to the environment, despite the higher content in fines particles, which is designed to create a cleaner work environment.

Tissen says that apron conveyors are particularly efficient for the transport of clinker. In general, the clinker should cool down to the ambient temperature plus 80°C, but during the process a so-called ‘raw meal flash’ can occur in the shell section of the preheater tower, caused by breaks in the kiln outlet sealing. “It doesn’t happen often, but it does happen. It can’t be completely avoided,” Tissen explained. Within a few seconds, several tonnes of raw meal or clinker run through the cooler. The material cannot cool down and arrives on the conveyor at extremely high temperatures.

“The cement plant operators are still not able to ensure with 100% certainty that the material does not leave the clinker cooler at temperatures of 500 to 800°C,” said Tissen.

He adds that Beumer Group apron conveyors are completely heat-resistant. The specific design of the cells allows safe, low-friction transportation of any hot material. Sealed and overlapping side walls and bottom plates in the cells prevent the clinker from exiting and minimise the escape of dust. Operators get the Beumer apron conveyors SZF and GSZF with cell-width gradations from 500mm to 2,000mm, centre distances of more than 250m and conveying capacities of over 1,300m³ per hour.

Beumer claims that the use of its steel wire belt instead of a chain lowers maintenance costs and extends maintenance intervals. Chains can also break, if preventive maintenance is not performed properly, which will lead to the conveyor collapsing. “The belt with the steel wires only ages and the rubber becomes brittle, but it would never completely break,” said Tissen. Lubrication is also not required for the belt, whereas it is used frequently on a chain, if for no other reason than to reduce noise levels.

Grease and oil are not only a cost factor, but are also detrimental to the environment and the conveyor. The clinker dust gets stuck on it and settles in the chain links, which accelerates the wear and tear. Beumer’s belt apron conveyors are in operation for nearly 150 companies.

In Eastern China a coal plant had belt damage, spillage and dust issues at two conveyor transfer points with outdated equipment in the loading zones. Raw coal ore was loaded onto the 1,000mm-wide belts traveling at 500 fpm (2.56 mps). The first chute had a 5m-high drop chute that loaded into a 12m-long loading/stilling zone. The second chute had a similar drop, discharging into a 26m-long loading/stilling zone.

Suffering from an old design, the belts were supported by impact idlers and a troughed roller system, neither of which was equipped to cope with new production demands. Equipment failures happened regularly, and without proper accessibility for routine maintenance, long periods of downtime were common. Belt sag created gaps between the belt and rollers, causing fugitive dust emissions throughout the facility.

Inadequate impact control led to spillage becoming entrapped between the belt and tail pulley, damaging them both. Excessive downtime, costs for cleanup and equipment replacement seriously impacted profitability. Managers at the coal plant sought a solution that better protected the belt, sealed the chute from dust and spillage, and offered easier inspection and ongoing maintenance.

Technicians from the Chinese division of bulk materials-handling solutions provider Martin Engineering were invited to perform an on-site assessment and suggest an affordable solution.

After offering a detailed proposal, the team installed modern equipment that addressed the issues on both conveyors. The first chute was equipped with a track-mounted impact cradle to improve loading and protect the belt and tail pulley. In addition, slider cradles for smoother centering were installed, along with a full-length apron seal to prevent dust and spillage from escaping. A comparable solution was installed in the longer chute, with added cradle support down the entire length. Both chutes featured non-powered dust-bag systems to collect emissions.

Since installation, Martin Engineering says that spillage around the loading zones is under control and dust emissions have been drastically reduced. Operators report that a considerable drop in equipment failure rates has resulted in a substantial increase in productivity. Contributing to the success was workers’ ability to easily inspect and service components by sliding them out and servicing them outside of the conveyor.

“After more than 75 years of working with bulk handlers all over the world, Martin Engineering has discovered that ‘access’ is a common element for both safety and productivity across all industries,” said Daniel Marshall, product engineer at Martin Engineering. “By adding easy access and monitoring in the design phase, equipment can be better maintained using less labour, leading to reduced downtime. This is reflected in the cost of operation, offering a better overall return on investment.”

Many conveyor transfer points still have an antiquated roller system tasked with absorbing impact and centering the cargo, according to Marshall. “These components often break and seize, causing friction and a potential fire hazard,” he said. “To replace them, several workers must remove the skirtboard and break the plane of the conveyor to reach across the stringer with heavy tools to assess and repair equipment.”

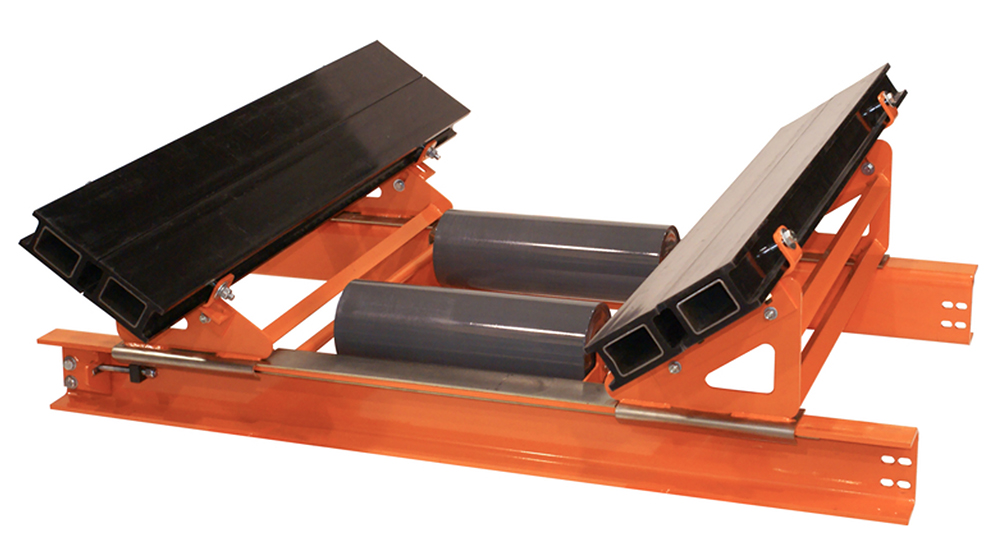

To reduce maintenance time and labour, improve safety and extend equipment life, operators should consider track-mounted impact cradles and belt support cradles. Located under the skirtboard and mounted with rugged steel assemblies, the cradles feature large impact-absorbing UHMW polymer ‘box bars’ engineered with smooth surfaces that the belt can slide across with little friction or belt wear. These assemblies can be pulled out by a single worker and – working safely from outside the conveyor and using only a single tool – the box bars can be simply removed and flipped in a matter of minutes to double the service life.

Along the cargo path in the settling zone and beyond, retractable idlers support the belt and maintain the trough angle. Exposed to the punishing environment, gritty dust and extreme weather, rollers can seize over time. Often set closely together in the loading zone to avoid belt sag, slide-out/slide-in roller frames permit workers to perform idler service outside of the belt plane without the need to raise the belt or remove adjacent idlers.

“Wear parts such as belt cleaner blades need to be monitored, serviced or changed regularly to prevent carryback from causing dust and spillage along the belt path,” Marshall said. “However, blade adjustments and changes can require several hours of downtime.”