Heidelberg cement's Bernard Mathieu talks to ABE about the need for construction materials businesses to calculate carbon footprints

Mitigation actions for reducing the human contribution to the observed global climate change are in the focus today," said Heidelberg Cement director global environmental sustainability Bernard Mathieu. "Climate change is probably the most prominent environmental challenge today, together with the ongoing loss of biodiversity.

"In addition to related regulatory developments, I have observed a growing interest from citizens and businesses for the climate impact of the products and services they purchase from suppliers. This interest is also growing in the construction sector, where businesses start to request product related environmental data from their suppliers.

"In particular, customers in the construction sector do become more and more interested in the carbon footprints of the products they are buying. On the other hand, suppliers discover carbon footprint as a marketing tool." According to Mathieu, Heidelberg also faces a growing number of requests on the environmental performance and/or the carbon footprint of its products, mainly from major construction companies or contractors with a high level of technical expertise and for flagship projects - which represents today less than 1% of its cement volumes worldwide.

The strategy of Heidelberg to answer those requests is based on three parallel approaches. The first is promotion of life-cycle assessment of the construction project covering all main environmental impacts. The main life-cycle stages of a building are the manufacturing of the building materials, the erection, the service life and demolition including processing of the residue.

"In the whole life-cycle of a building today most impacts occur in the use phase of the construction," said Mathieu.

"We believe that life-cycle assessment is the only rational and consistent methodology which enables an objective choice of the building materials. Indeed, a specific building material could have a relatively higher initial carbon footprint but contribute at the same time to significant CO2 emission reductions during the lifetime of the building or the demolition and recycling phase. With its high thermal mass, Concrete is known to contribute to mitigation of the CO2 emissions related to the heating and cooling of the buildings during their operational life." Mathieu adds that global warming is not the only environmental challenge our world is facing and all environmental impacts should be taken into account to define best choices. "So-called 'Environmental Product Declarations (EPD)' provide a holistic picture of the impacts, including carbon footprint, energy consumption, water footprint and resource depletion," he said. A new standard for EPD for construction products will be published in 2011 (prEN 15804 Sustainability of Construction Works - Environmental Product Declarations - Product Category Rules).

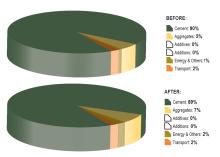

"In other words, single scores like the carbon footprint are easy to grasp but don't give the whole picture," said Mathieu In the second element, Heidelberg wants to fully take its responsibilities for the manufacturing phase of the building materials. "With improvement of energy efficiency of buildings (triggered by new and upcoming regulations) and life-cycles that become shorter the impact of the construction phase will become bigger and the focus on the carbon footprint of building materials will undoubtedly grow," explained Mathieu. "Heidelberg is committed to reduce its CO2 emissions per tonne of cement. Between 1990 and 2009, a reduction of more than 19% of net specific CO2 emissions per tonne of cement was achieved and the improvement is still going on." The final part of the approach involves Heidelberg's commitment to inform the market about the environmental performance of its products, as clearly stated in its Sustainability Ambitions 2020 document. "We developed internal expertise in the assessment of the environmental impacts of its products, including the carbon footprint and is willing to enter into a constructive dialogue with its customers in order to promote best practices in sustainable construction," said Mathieu.

"In this proactive approach, we are facing some practical difficulties. Today a large number of different carbon labels exist, based on different protocols and standards, and the information on the CO2 footprint might not be comparable.

"Standards leave some room for choice and interpretation, among others related to the system boundaries (what is included in the calculation and what is not) and the allocation of emissions between co-products (defined as being two products from the same process). We promote a direct interaction with its customers to address the methodological issues and the considered assumptions.

"We base our customer relation on transparency and openness - this is especially true for questions related to the environmental impact of our products."