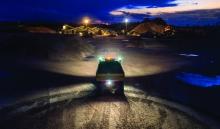

The quartzite quarry in Austertana in Finnmark, Norway’s northernmost county, is one of the world’s largest. At some 350m above sea level, the quarry is imposing, and it is necessary to carry the quartzite 3km down the hill to the crusher and nearby quay, which is 40m above sea level.

The transport road, which among equipment and vehicle suppliers is regarded as the world’s toughest, has a gradient slope upwards of 1:7.

Material transport is being handled by three

LNS (Leonhard Nilsen & Sønner) has had a contract since 2001 with Elkem Tana to mine quartzite in Austertana, and each year it drills, blasts and transports approximately 1.2 million tonnes of quartzite used by the ferrosilicon industry throughout the world.

The open-pit mine in Austertana is one of several northern Norwegian mines where LNS is the operating contractor. The three new Cat 775G trucks at Austertana, each with a capacity of 63.5tonnes, work two shifts from 6am to midnight. During each eight-hour shift each of the trucks does around 20 runs.

In addition, 200,000-250,000tonnes of quarry waste are carried annually from the quay level to the storage site 220m above sea level.

“The new G series and older F series [LNS has had an F model since 2009] are fairly similar on the outside, but not inside,” says Per Olav Listou, key account manager at Norway’s Caterpillar dealer Pon Equipment.

“The G-series engine has 5% more horsepower, 825hp [607kW] and torque of 4,269Nm all the way down to 1,200 rev/min and up to 15% lower fuel consumption.

“The ACERT engine with compression brake (Jake Brake) acts as a compressor and increases braking capacity by approximately 35%. What happens is that the exhaust valves open and release compressed air through the compression stroke of the engine. Electronics control the interaction between the retarder and engine brake.

“At the top of descent to the quay the driver can put the truck in fifth gear and let the electronics control the retarder and the engine as the truck makes its descent. The driver therefore has a comfortable ride and can concentrate on watching the instruments,” says Listou.

Heavy duty brake lining consists of carbon fibre lamellas that can withstand high heat, thus increasing longevity, and the internal sound level in the cab has been reduced from 79 to 74d(B)A.

“Cruise control and the VIMS monitoring system (expanded monitoring of machines and weights system) are standard on the G models, which also feature a new rear axle with strong components,” says Listou.

The LNS trucks are loaded by a new Cat 390DL excavator. The 95tonner, with 523 hp (390kW) is equipped with a 5.7m³ Cat bucket with Cat J800 teeth.

“The 390 is well adapted to the 775G truck, which is loaded with 7-8 buckets in just over two minutes. The excavator’s driving comfort, electronically controlled hydraulics, separate swing pump and plenty of digging power are key to short cycle times,” says Listou.