BKT has launched the new 875/65 R 29 L-5 size for its EARTHMAX SR 51 OTR (off-the-road tyre) range.

The Indian-headquartered manufacturer says the new 65-series tyre line is specially designed for wheeled loaders working in aggressive applications, in highly abrasive rock quarries and landfills. It adds that this is possible thanks to the cut-resistant extra deep L-5 tread, that offers excellent cut and puncture protection and longer wear life.

EARTHMAX SR 51 also features an extra sidewall protection for exceptional traction and durability. Its strong all-steel structure and cut-resistant compounds are designed to help increase productivity and operating hours, preventing downtime due to tyre damage.

The low-profile design and reinforced beads provide stability and lead to a longer life while the square-shaped shoulder laterally ejects gravel and reduces the risk of punctures.

The new 875/65 R 29 L-5 size adds to existing 17.5 R 25, 20.5 R 25, 23.5 R 25, 29.5 R 29, 35/65 R 29 and 35/65 R 33. All of them feature the special L-5-class tread with cut-resistant compound and are very popular sizes for all loading applications, meeting the demanding needs of OTR equipment applications globally.

EARTHMAX SR 51 is one of the wide range of tyres in the EARTHMAX line specifically designed to promote a better distribution of loads for dump trucks, wheeled loaders, dozers, graders and some multi-purpose vehicles. BKT says the range brings together in a single line over 20 different tyres for the OTR sector that vary depending on the application, the surface and the machinery. They are also available in numerous sizes and compound variants.

BKT commented on the new range: “EARTHMAX is constantly expanding and evolving, and this is because every user has specific needs to which BKT intends to respond.”

Trelleborg has confirmed media stories that external parties have shown interest in acquiring its Trelleborg Wheel Systems OTR business.

The Swedish tyre manufacturer stated in December: “Discussions at an early stage are ongoing with external parties. At this stage, Trelleborg will not communicate any further on this matter. Should the discussions advance and develop into a situation where additional information is relevant, this will be communicated.”

In the same month Tyres & Accessories publication reported that Japan-based Yokohama Tire has made a bid worth approximately US$2bn for the Trelleborg Wheel Systems operation to further expand its growing off-highway tyre business.

The global OTR tyres sector is exhibiting ongoing acquisition and consolidation activity.

In December 2021 Bridgestone confirmed that it had completed its acquisition from Downer EDI of Otraco International, an Australian-based provider of OTR tyre management solutions. The acquisition was carried out through Bridgestone’s Mining Solutions Australia operation.

Bridgestone says the acquisition will accelerate the growth of its global mining solutions business and expand the company’s service network in key markets such as Australia, Chile and South Africa.

Otraco offers a portfolio of OTR tyre management solutions that track tyres across the full lifecycle, such as its computerised Otracom platform. Bridgestone says Otraco’s offering will complement its own OTR products and solutions, including Bridgestone MasterCore surface mining tyres and the tyre monitoring and management solution.

All business assets, including Otraco’s sales offices and training facilities, OTR customer relationships and the company’s approximately 860 employees are transferring to Bridgestone. The transaction is valued at A$79m (US$56.45m).

As outlined in the company’s mid-term business plan, Bridgestone says it is strengthening investments in its core tyre business while also pursuing M&A activities that expand and enhance its sustainable solutions offering.

Bridgestone adds that its mining tyre and solutions operation is an important business in which the group continuously and proactively injects its strategic resources.

Dutch OTR manufacturer Magna Tyres Group announced at the start of 2022 that it is to acquire Polish tyre dealer Industra. Magna says that Industra has a very strong position in Poland as it is the biggest supplier of speciality tyre services. The company works with three product categories: industrial tyres (from forklifts to port handling machines), tyres for earthmoving machinery and the agricultural sector (tyres, wheels and tracks).

Magna adds: “In its 24 years of existence, Industra has achieved the position of first-choice partner for the largest end users of specialty tyres in Poland due to the experienced staff, on-site services and the widest stock in specialty tyres.”

Magna says that with this acquisition and the existing Magna Tyres Poland operation, it appears to be “the strongest player on the market of industrial and OTR tyres in the region of Central and Eastern Europe”.

In December, Magna also bought Australian-based Fennell Tyres International for an undisclosed sum. Magna says that Fennell Tyres International is known for its competitively priced, high-quality OTR, mining and TBR (truck and bus radial) tyre solutions.

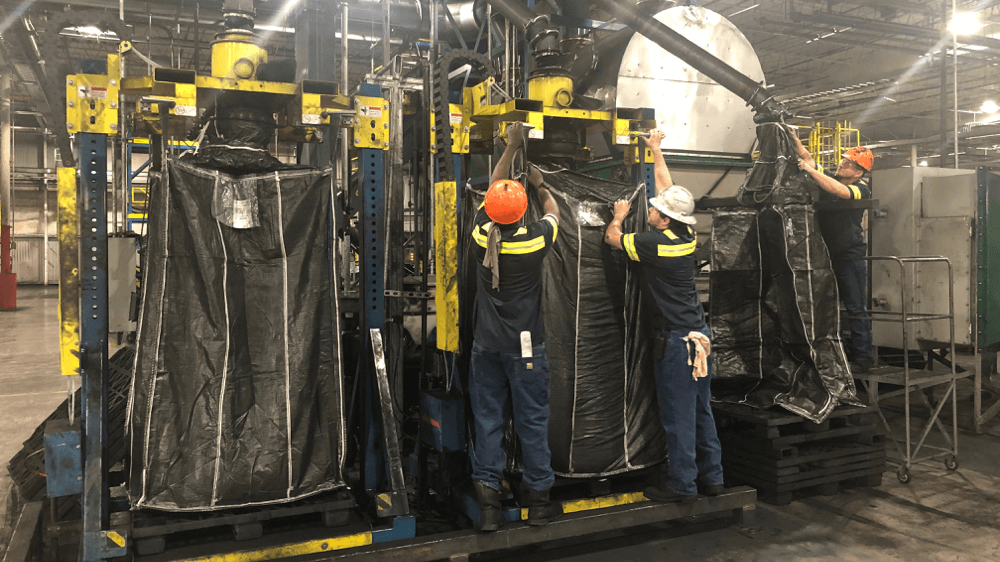

UK aggregates, recycling and skip hire business PSH Environmental says it has eliminated all instances of punctures across its fleet of Volvo wheeled loaders by utilising Michelin’s ultra-durable X Mine D2 Pro tyres.

PSH adds that it specifies all new machines with the Michelin fitments, having found them to be highly durable in addition to offering a much-improved level of comfort and performance over a solid waste tyre.

Nigel Parker, who runs PSH Environmental with his brother Martyn, says: “We fit the Michelin product because it is by far the best option for our wheeled loaders. The Volvos are fantastic machines, working in a very tough environment and we use a premium tyre to ensure we get the best out of them and avoid costly downtime.

“Unless you are very, very careless you really cannot puncture these tyres. The only other option for us would be to run solid tyres, but we have avoided that as the ride quality is so poor and, working on concrete, you can end up damaging the machine.”

PSH Environmental currently runs three Volvo loading shovels – one older L60H and two new L90H machines, all supplied by SMT GB. The L90H is the latest addition to Volvo’s H-Series, offering a higher load capacity and greater lifting height than any of its predecessors.

Michelin and Bridgestone have set out their shared perspective regarding material circularity and the ambition to increase the utilisation of recovered carbon black material in tyres.

The OTR manufacturers made a joint presentation at the Smithers Recovered Carbon Black Conference in Amsterdam on November 22, 2021

An estimated one billion tyres around the world reach the end of their useful service life every year. Many of the technical challenges surrounding the use of recycled and recovered materials from end-of-life tyres are understood, but barriers remain towards achieving material circularity at the scale necessary to realise a more sustainable mobility ecosystem. Today, less than one percent of all carbon black material used globally in new tyre production comes from recycled end-of-life tyres due to a weak supply pipeline for the recovery and reuse of carbon black.

Recovered carbon black presents the opportunity to reduce the tyre industry’s reliance on petrochemicals by replacing a portion of traditional carbon black with a sustainable and circular alternative without introducing performance trade-offs. Additionally, using recovered carbon black in new tyre production reduces CO2 emissions by up to 85% compared to virgin materials.

At the conference, the two companies outlined a path aimed at promoting and increasing the utilisation of recovered carbon black in new tyres and other rubber products. Collaboration with stakeholders across all aspects of the tyre and rubber industry value chain will be needed to deliver this goal. As such, Michelin and Bridgestone seek to establish a coalition of a diverse group of stakeholders, including tyre manufacturers, carbon black suppliers, pyrolysis partners and emerging technology startups to accelerate progress and increase supply of recovered carbon black.

“Increasing use of recovered carbon black in tyres is critical to achieving Bridgestone’s vision for sustainable mobility,” said Jake Rønsholt, vice president of strategy and transformation, Bridgestone Europe, Middle East, India and Africa. “Together with Michelin and other stakeholders, we can generate critical momentum on this important initiative and advance our efforts to reduce CO2 emissions and manufacture products from fully renewable and sustainable materials.”

As part of the joint initiative, Bridgestone and Michelin will lead the development of a position paper that will outline the tyre industry’s role in achieving a circular economy.

Bridgestone says that increasing the use of recovered carbon black in tyres is critical to achieving its vision for sustainable mobility. “Together with Michelin and other stakeholders, we can generate critical momentum on this important initiative and advance our efforts to reduce CO2 emissions and manufacture products from fully renewable and sustainable materials,” Bridgestone states.

The two manufacturers say their initiative is not centred on investment, but instead focuses on creating a needed dialogue about utilisation of recovered carbon black material across the tyre and rubber value chain.

Bridgestone has made a minority investment in Delta Energy Group, which specialises in material recovery from end-of-life tyres and is a supplier of recovered carbon black material to the company’s Americas business.