Innovations in the washing sector are supporting quarry operators and materials processors alike to overcome the challenges stemming from water management; cost-based, efficiency, sustainability and regulatory.

Prominent among these is the modular wet processing equipment from CDE. The Northern Ireland-based company says its solutions can contribute to the easing of water scarcity issues arising from the materials processing industry’s consumption of water resources, significantly improving water efficiency, and better wastewater management practices. It adds that developing technological solutions to tackle these mounting challenges is paramount for many materials processors seeking to boost the profitability of their operation by minimising the consumption of costly water resources.

Stefan Hunger, CDE regional manager for Europe & Russia, and Daniel Webber, CDE regional manager for Australasia, report increasing regulations governing the responsible use and management of water in the industry, including those aimed at protecting marine environments and water sources from pollution and over-abstraction.

Hunger says: “It’s important to acknowledge that water is renewable when its usage is regulated and managed responsibly, but it is also a finite resource. Not only does water recycling make sense from a global environmental perspective backed up by increasingly stringent legislative requirements, but it also ticks all the right boxes in terms of return on investment.”

In Europe, there are approximately 26,000 aggregates sites, nearly 60% of which are involved in materials washing activities.

Webber explains that the Australian mining industry has adapted to more regulations surrounding its water usage than most other industries.

“Each stage of the mining cycle requires permits, including, among other utilities, water permits. The impact of operation is also subject to strenuous environmental assessments to evaluate the management and use of water resources and the processes that will be employed to prevent the contamination of groundwater.”

In terms of sector, agriculture remains the largest user of water in Australia, accounting for almost 70% of total water footprint. Industry, however, including mining and quarrying, is on the rise at a time when water storage levels hit a 10-year low in 2019/20.

Webber continues: “Pressure on Australia’s water resources is mounting on account of population growth. With this comes greater demand within the agricultural and industrial sectors to support such growth and urbanisation. We’re finding mine and quarry operators are in effect competing against the needs of urban populations, farming, and the environment in terms of water demand which is why governments are taking greater action to regulate its use.”

CDE says it is therefore increasingly crucial for materials processors to invest in an effective water management strategy that ensures a steady supply of clean water to their plants through cost-effective means.

While laws governing water vary around the world, it is a resource that is essential to the extractive industries and is therefore increasingly under the water management microscope.

Earlier this year, in the United States, the Environmental Protection Agency (EPA), provided further clarification to its Waters of the United States (WOTUS) rule which aligns with the Clean Water Act.

Darren Eastwood, CDE business development director for North America, explains: “Confusion caused by the 2015 WOTUS rule resulted in many aggregates businesses across North America incurring high costs due to the uncertainty around when federal permits were required. Its reclarification provides a clear regulatory framework to which aggregates producers can align. Its new definition clarifies that pits and water treatment basins are not subject to additional federal regulation.”

Water as a resource delivers economic value to a range of industries. Within the extractive industries, the value of materials significantly increases when washed, but wet processing in mining and quarrying operations is dependent on water availability and processing plant efficiency.

Hunger comments that customers do want to wash: “But footprint, particularly in urban settings, is prohibitive. This is why CDE has invested significant resources into the design and development of compact and modular equipment that can be commissioned in urban areas while also offering the ability for future migration of the plant to where opportunities lie.”

Webber adds: “More often it’s water availability and access that prevents producers from getting into the washing business in the first place. That, and the uncertainty around typical top-up water requirements which, in the case of CDE water management solutions, are very low. The focus is on recycling and recirculating as much water as possible through the system.”

Bruno Paladino, CDE regional manager for Latin America, says the combination of regulatory and environmental considerations with economic factors presents a significant challenge for operators washing sand and aggregates.

“Water supply is a key determining factor when assessing the viability of a new project or when considering expanding operations at an existing site,” says Paladino. “Insufficient water supply, particularly in arid regions, will drive up operational expenditure costs significantly in an industry where energy prices already represent 20% of these costs due to the investment in water infrastructure to ensure an adequate supply of clean water is pumped into the plant.”

In the Americas, customers using settling ponds to recycle water often encounter significant operational and logistical challenges.

Eastwood explains: “These require constant maintenance as they accumulate sludge, silt, and other solids that must settle and separate from the water before its removal. Not only do these limit the water storage capacity of the pond, but they incur significant maintenance costs. Further still, the limitations of settling pond systems often result in the loss of valuable fines, one of the key considerations in the design of CDE water management solutions.”

Paladino stresses the importance of safe water management in all regions but highlights the urgent relevance of such practices in Latin America.

“Over the past few years, mines in Latin America are looking for new and sustainable ways to continue their exploration, ways that are less impactful on the environment and surrounding communities. The use of water is a key factor, as is overall footprint and energy usage. CDE’s modular plant design with water recycling system is the perfect fit to help mines meet these new challenges.”

CDE says it consistently invests in research and development to enhance the capabilities of its premier water recycling and management equipment. At the forefront of its water recycling systems is the AquaCycle, a single, compact unit suited to high and low tonnages across many markets.

AquaCycle is designed to accelerate return on investment by maximising production efficiency, minimising the loss of valuable fines, and reducing water and energy costs.

According to Dennis Zink, global product manager at US-based water management solutions provider McLanahan, filter presses provide the best solution for the issue of settling pond elimination.

He adds that several types of dewatering equipment are available to separate solids and liquid in slurries to reduce or eliminate settling ponds, but one is better for overall tailings and water management.

The aggregate and mineral industries have historically used the simplest and cheapest dewatering technology to manage waste slurry tailings. These old methods include dumping directly into streams, rivers and lakes or using mining surfaces or underground quarries/pits for disposal.

For a number of decades these industries have been pressured to eliminate older ways of waste dumping and look for more efficient waste management technologies.

Initial improvement in tailings management technology involved creating ponds or large impoundment dams to hold the waste slurry for the life of the quarry or mine.

Over the past 10 years or more, pressures to improve tailings management practices have increased further due to a number of factors. Zink states that these include stricter environmental regulations, rising operational costs, higher waste handling costs, increased water conservation requirements, catastrophic impoundment failures, the need for better risk mitigation, and physical space limitations for operational expansion.

Zink adds that leaders in the aggregate and mineral industries have started evaluating and investing in more efficient, cost-effective systems to dewater tailings. The systems include: ultra-fines separation, slurry thickening and slurry dewatering equipment technologies.

The UFR (ultra fines recovery) and thickener equipment technologies separate and concentrate the waste materials, while the dewatering equipment recovers additional water from the waste stream and creates nearly dry solids.

The types of competing dewatering equipment used in the aggregate and mineral industries today include plate filter presses, belt filter presses and centrifuges.

Centrifuge dewatering is a high-speed process that uses the force from the rapid rotation of a cylindrical bowl to separate wastewater solids from liquid.

Zink says: “These dewatering devices work best with material that is more easily dewatered, has a larger particle size distribution and/or a low clay content, though they generally are not going to be as efficient as a filter press since they cannot generate the high-pressure dewatering forces of the latter.”

Centrifuges operate as continuous feed units that remove solids by a scroll conveyor and discharge liquid over the weir. Centrifuge equipment has high up-front investment cost and high operating cost. It is built to tight mechanical design specification to operate efficiently at very high rotational speeds. Operating costs are high due to significant electrical power requirements, expensive replacement parts and the need to use dewatering chemicals.

Belt filter presses are another type of equipment used to remove water from waste slurries to produce a non-liquid material referred to as a “cake”. In a belt filter press, the waste slurry is forced between two tensioned porous belts. As the belts pass over and under rollers of various diameters, the liquid is squeezed out of slurry while the solid cake material is retained between the belts.

There are many designs of belt filtration processes, but all incorporate some basic features: polymer conditioning zone, gravity drainage zones, low-pressure squeezing zone, and high-pressure squeezing zones. Advanced designs provide a large filtration area, additional rollers, and variable belt speeds that can increase cake solids by 5%.

Belt filter presses have low to medium initial capital cost, with a smaller footprint for installation. Operating costs tend to be high due to the need for a full-time operator and the use of chemical dewatering aids. Belt presses have a reputation of requiring frequent belt washing and are very sensitive to process variations.

Recessed plate filter presses are used to create a dewatered cake material by separating the liquid and solid materials in waste slurries. These filter presses are among the oldest types of dewatering devices and are commonly used in aggregate and mineral processing waste slurry applications.

The up-front investment for a plate filter press can be high due to the size of the equipment and required support structure.

Depending on the type and amount of material being dewatered, McLanahan’s Zink states that modern filter press equipment can be very big and require a large space for installation and operation.

Plate filter press operating costs are low due to the requirement of only a part-time operator, lower wear parts cost and typically no need for chemical dewatering aids.

Because the slurry material is captured completely between the filter plates, very high dewatering pressures (up to 225 psi or higher) can be applied to the slurry. The high dewatering pressures produce the highest cake solids concentration possible of any mechanical dewatering equipment.

Plate filter presses can also employ a second type of plate called a membrane plate. In this case, the plate has a flexible membrane surface made from polypropylene or other synthetic flexible material such as hard rubber. The membrane can be thermally fused to the concave plate core, or the synthetic membrane’s edge can be embedded into the concave plate core in a small channel machined in the plate surfaces.

The same initial process is used in a membrane plate press, with a high-pressure slurry pump feeding the press to fill and dewater as much slurry as possible.

After the slurry feed pump is stopped and while the filter plates are still clamped together, the membrane surfaces are expanded using compressed air or water. This inflated membrane compresses the cake material, removing additional moisture to the lowest possible levels.

Zink says that no other dewatering process has shown to be more efficient at removing liquid from slurries as the plate filter press. He adds that additional benefits of plate filter presses include: the highest amount of recovered water, driest cakes, lowest operating cost, lower waste handling cost, less water hauled, and most stable solid material generated

“Because of these advantages and the high efficiency of the plate filter press, it is the best choice of equipment to eliminate settling ponds,” Zink adds.

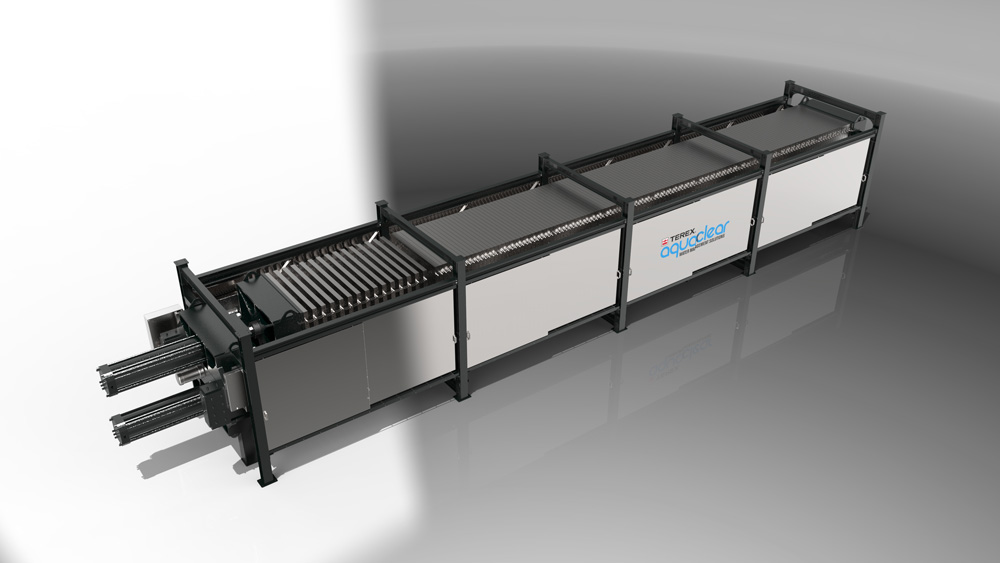

Northern Ireland-based Terex Washing Systems (TWS) has a product portfolio that includes Terex AquaClear Water Management Solutions. Barry McMenamin, TWS business line director, highlighted the benefits of the water management solutions, commenting: “A lot of our customers have a need for water management, which is a continually growing sector given the way environmental legislation is evolving in certain regions.”

TWS water management portfolio includes clarifying tanks, flocculent dosing systems, filter presses and all associated equipment to provide a one-stop solution. With installations globally the company says it is leading the way in providing ‘End to End Washing Solutions’ from a single source supplier.

Water management solutions vary in size and complexity, but generally comprise three stages; flocculation, sludge thickening, and de-watering of solids via a filter press.

For stages one and two TWS offers a wide range of AquaClear floc dosing units paired with a choice of deep cone thickener, or low-level rake thickener. The choice of thickener is dependent on the application and the plant layout, according to TWS product manager Mark Follis.

“The deep cone thickeners offer a fantastic simple solution for sludge thickening,” says Follis, “with a small footprint, no moving parts, and the ability to use the natural pressure in the tank to achieve higher sludge concentrations over 50% solids, ideal for discharge directly to a sludge pond.”

For many applications TWS says stage one and two is the complete water management solution, with the AquaClear thickener providing 80% water recovery back to the main washing process, and the thickened sludge only being discharged to settling ponds, thus significantly reducing the area required for ponds or sludge storage.

An example of this was the recent TWS installation at Grahams Concrete in Queensland, Australia, where the DC140 deep cone thickener can be seen working alongside the AggreSand 165.

This natural sand and gravel application operating at 100tph feed rate requires only 30-40m cubed/hr top-up water to keep the system running, while flocculant usage is optimised using the AquaClear DCU (dosing control unit) which continually monitors sludge settlement rates to ensure the correct dose of floc is provided to the plant.

Adding stage three, TWS says that its AquaClear filter press maximises water recovery by creating a completely closed-loop system, where sludge is dewatered under high pressure and expelled as solid filter cakes with a dry solids content of up to 85%.