Based on an enhanced calcium sulfate binder, Supaflo Rapide presents considerable time-saving benefits during installation while also dramatically cutting down drying time and offering an improved carbon footprint compared to traditional screeds.

Extensive laboratory testing and plant trials have demonstrated that floors installed with Supaflo Rapide screed, at typical thicknesses, achieved a moisture condition of <75% relative humidity (RH) at between 10 and 15 days under controlled conditions.

This means that it is often possible to apply moisture-sensitive floorcoverings such as adhered vinyl and engineered timber flooring at around two to four weeks after the screed is installed; around half the time it would take for a standard calcium sulfate-based flowing screed to dry.

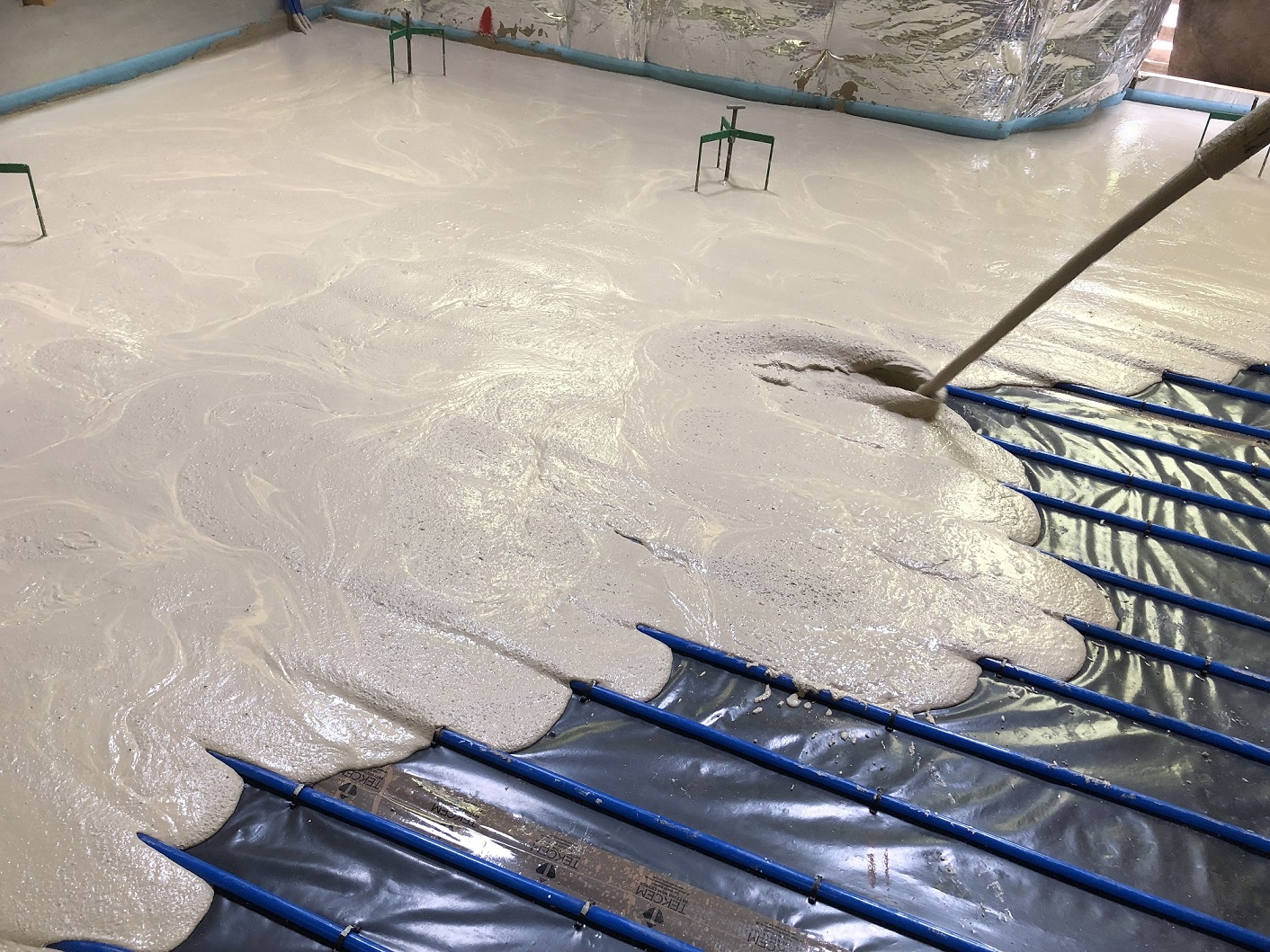

Supaflo Rapide is laid at reduced thicknesses, and up to 2000m2 can be installed in a day, providing significant productivity benefits and improved resource efficiency.

Perfect for all domestic and light commercial applications, including bathrooms and toilets, Supaflo Rapide retains all the benefits of standard Calcium Sulfate based flowing screeds such as ease of placement, dimensional stability, minimal plastic shrinkage and reduced potential for cracking, improved thermal conductivity. The product is self-compacting and can be installed on large scale projects.

Steve Crompton, director of Quality and Product Technology for CEMEX Materials West Europe, said: “Our technical expertise has enabled us to develop a new, more sustainable, premium quality screed that will help increase the efficiency of the job site, allow effective use of labour and improve the climate impact of projects. Supaflo Rapide uses an enhanced calcium sulfate binder and the latest admixture technology to cut down on drying time while maintaining the speed of installation associated with these types of screeds.

“This will greatly benefit construction companies as they juggle the ongoing challenges of site working requirements alongside increasing demand for fast and safe completion of jobs with a lower environmental impact.”