The company claims it is the first to introduce embedded machine condition and runnability monitoring within process controls.

As a leading supplier in mining and construction machinery, it says the expertise is now combined with scalable Metso DNA automation systems that adapt to the diverse mining and construction industry needs, from single machine controls to entire plant-wide automation and information management systems.

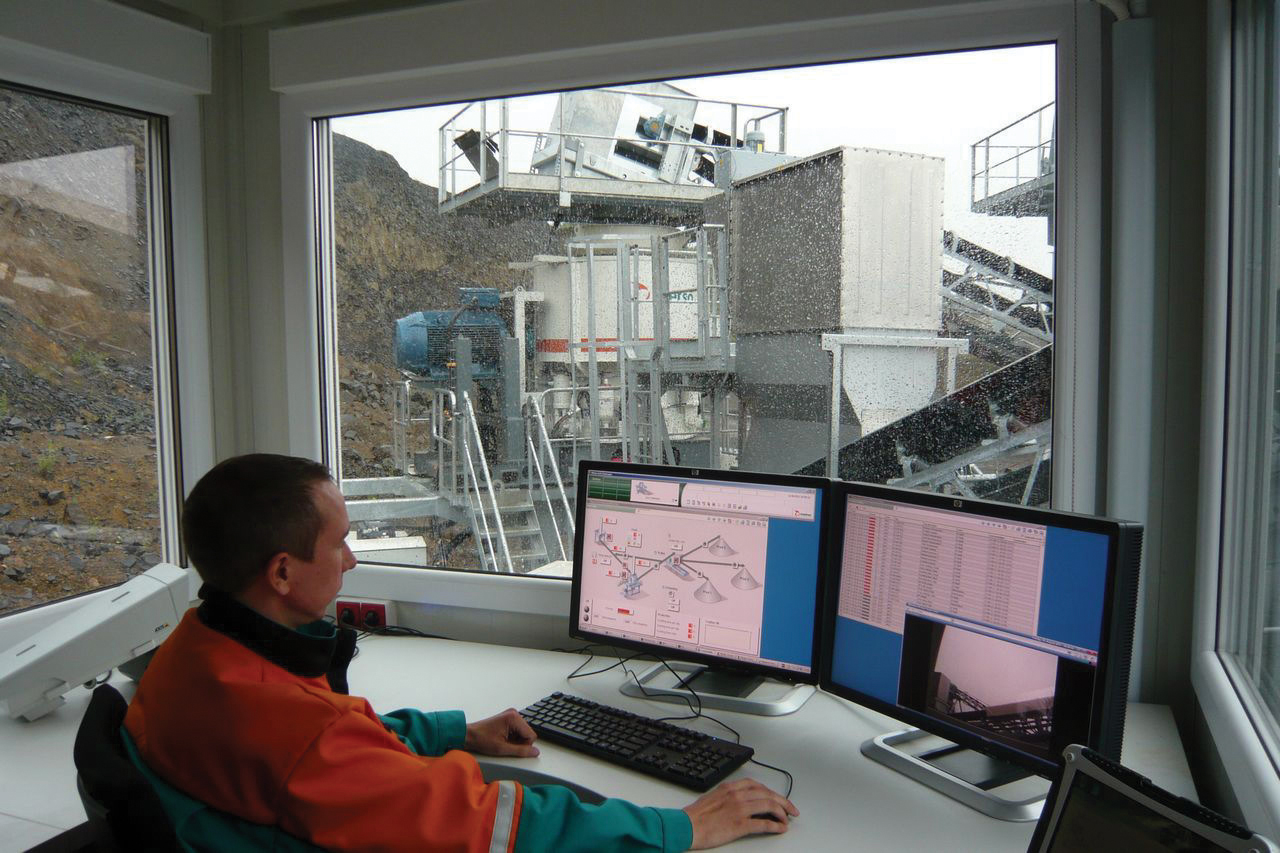

An example of Metso’s new offering is the new crushing plant control room solution that connects crushers and screens together, ensuring the effective management of the entire plant from a pleasant and safe control room.

The Metso DNA user interface provides production information to ensure a proper and rapid response to plant events. Automatic controls stabilise the process and allow the operators to monitor the plant as a whole.

“As an example of the services, we offer performance studies for crushing plants, using Metso’s multi-disciplinary teams of experts, to determine the present level of the plant and process efficiency, and to estimate the improvement potential and benefits from optimisation and automation, including return on investment (ROI) calculations. As another example, our machine condition monitoring solutions can reduce plant and machine downtime as well as help avoid safety and environmental hazards,” says Mikko Mäkinen, product manager of minerals applications in Metso’s Automation business line.