The company says the pump is designed to deliver increased efficiency where water needs to be lifted over greater heights, a common requirement in both open and underground mines, and the unit delivers efficient operation at heads of up to 140m.

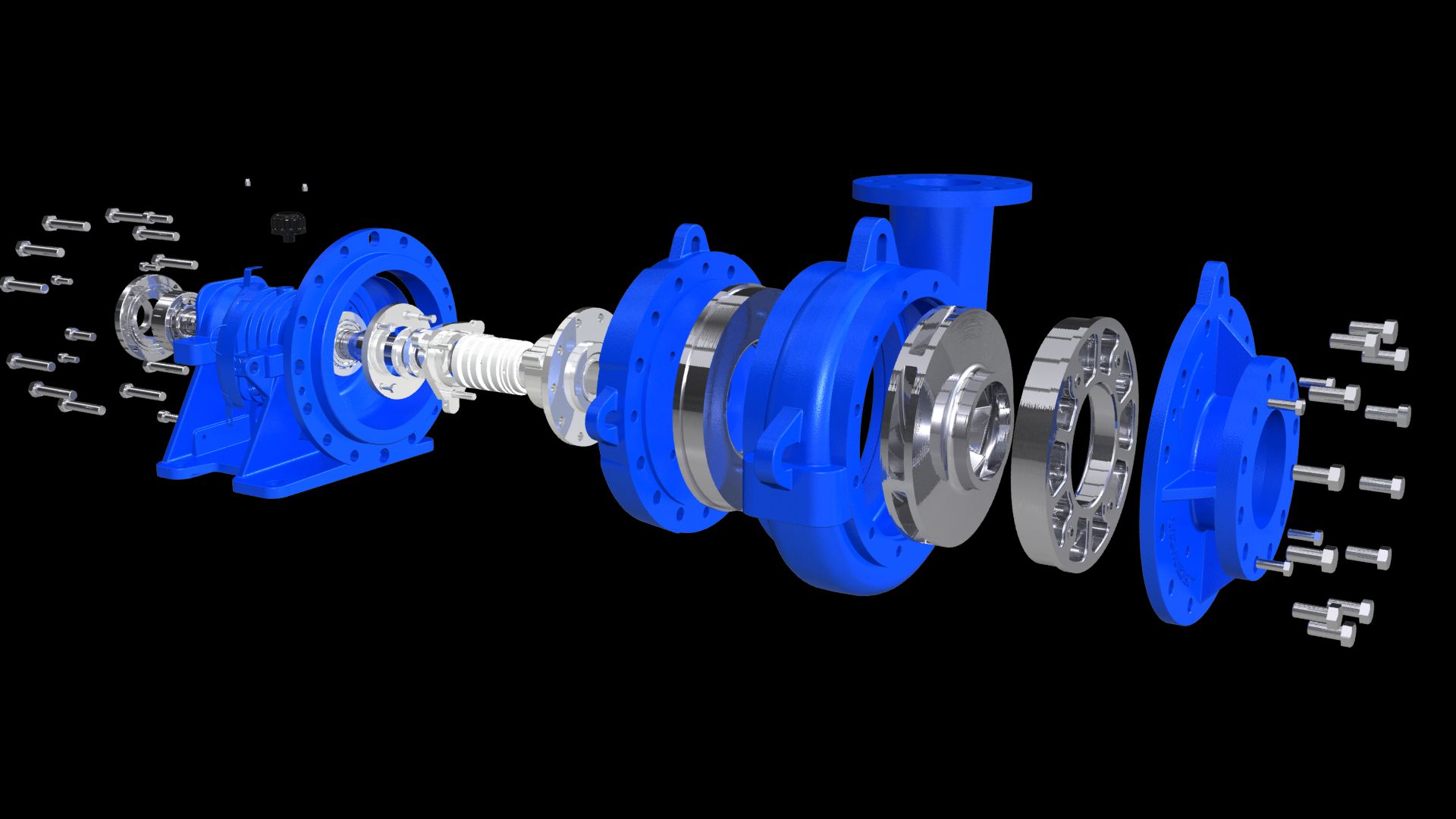

Four different sizes are available, with outlet diameters of 75mm, 125mm, 150mm and 200mm and around 50% of the parts used in the new design are interchangeable with Weir Minerals’ popular slurry pump, the Warman WBH, to help clients simplify spare parts ordering and holding.

Weir Minerals’ engineers have designed a new, double-volute casing which reduces radial load and is capable of maintaining internal pressures of up to 7,000kPa, allowing the pumps to be configured in series to deliver even greater head heights.

“The dewatering system is a crucial part of almost every mining operation around the globe, and we’re committed to ensuring that our range of dewatering pumps is broad enough to deliver optimum efficiency, whatever the requirements,” says Steve Sedgwick, the Weir Minerals Europe product manager for mine dewatering.

“We have used the latest computer-modelling technology to achieve a hydraulic design that is optimised for the high-head, high-efficiency dewatering challenges most commonly encountered by our customers, whilst maintaining a proper robust mining type pump.

“The DWU is designed specifically with heavy lifting in mind, so it minimises hydraulic loads on the internal parts, maximising efficiency and increasing the longevity of wear parts.

“Mechanically, the pump has been designed with heavy-duty mining applications in mind. A one-piece frame ensures it stays correctly aligned while ultra-heavy-duty bearings maximise wear life and reduce the whole-life cost of ownership.”