You have heard it before: Try to reach the maximum output with a minimum of effort. We are here to help you achieve this aim. Our crushing and screening solutions are complemented by a wide range of digital solutions, bringing optimal results even under changing conditions. The full digital experience consists of intelligent crushing, processes and operations optimization, and fleet management.

Intelligent crushing

If you are working at a quarry or if you are a private contractor, our intelligent crushing offering can help in both cases to improve the safety of your operations and maximize the productivity of your crushing processes. Automating the crushing and screening process is a core part of this offering. You will be delivered a control system that offers you monitoring and control features, ranging from a single machine or crushing stage to your full crushing process.

Intelligent crushing is built using robust hardware and is designed to work reliably in demanding crushing environments. Automation is there to reduce unexpected costly downtime. Intelligent crushing comes with the convenient advantage of being able to control your equipment remotely from a centralized climate-controlled facility, or even directly on-site, for example while working in an excavator. Intelligent crushing is also compatible with SCADA (Supervisory control and data acquisition) software and hardware system.

Process and operation optimization

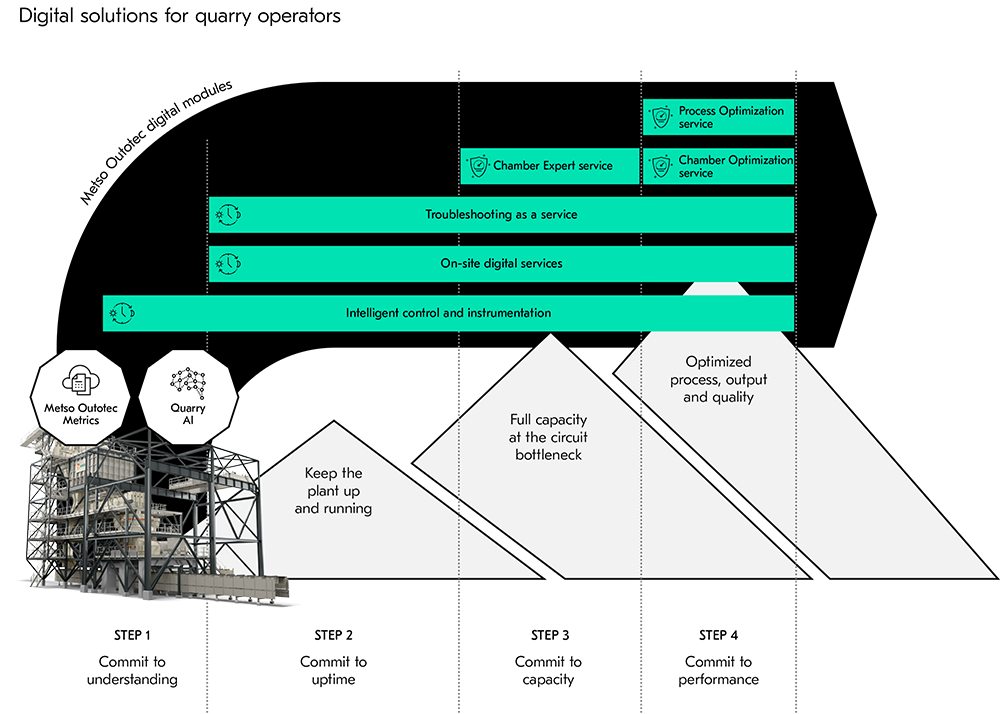

Process and operation optimization is an ideal service for quarry operators who wish to take the next steps towards reaching their full potential. The journey towards becoming a benchmark quarry starts from a workshop with our experts and the solution is built step by step based on the findings and targets.

The solution can be divided into three main categories: Automated and semi-automated performance optimization and operational optimization. An automated performance optimization will help to stabilize and optimize the way your quarry is operated. For crushers and screens, it is possible to reach new performance levels with semi-automated performance optimization. Operational optimization makes your parts management smarter, which will in return increase parts availability at site, enabling more running hours for your equipment.

When the necessary steps towards becoming the benchmark quarry are taken together, there will be a shared commitment to understanding, to uptime, to capacity and to performance. Our solutions will give your quarry more running hours and performance through our tailored approach with focus on sustainable and safe operation. This is achieved with our digital tools and experts.

Fleet management

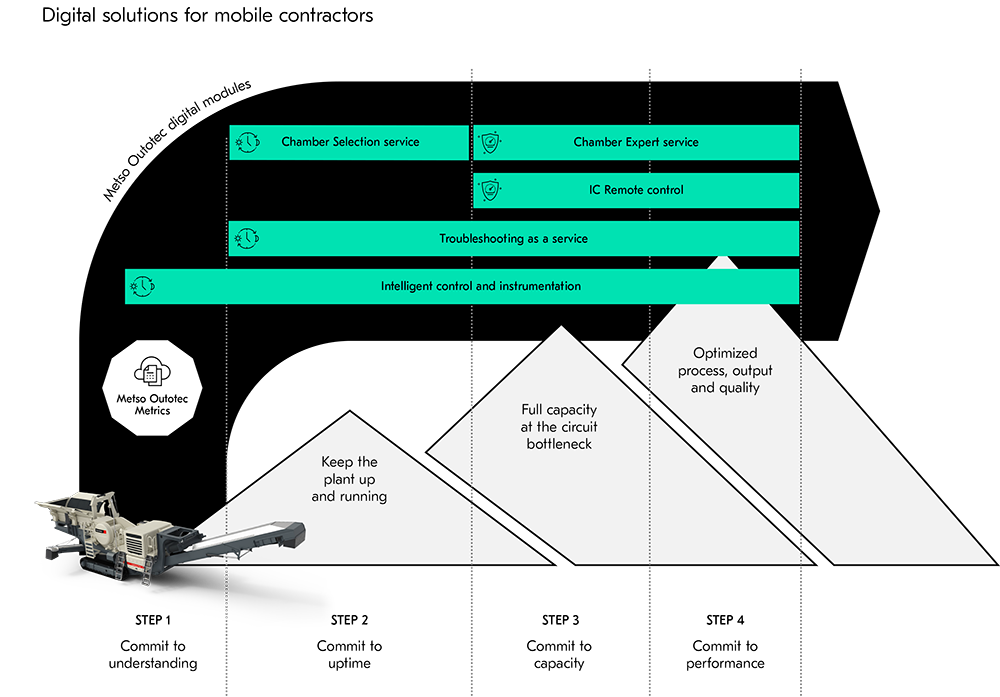

Fleet management is tailor-made for aggregate contractors and distributors who need to run their assets for maximum profits but minimum risk. Fleet management is an offering designed to monitor the fleet and optimize overall availability. Metso Outotec’s advantage lies in its offering, as it is supported and developed with over 100 years of crushing experience, an extensive distributor network and data analytics from the largest and most advanced fleet in the world.

Fleet management provides availability services including operating hours, performance services estimating the maximum production and end-product quality, and Protection Services (EPS) to secure the investment that has been made. Additionally, fleet monitoring ensures efficient management and a high resale value of the rental fleet.

Connected equipment is easy to own and maintain thanks to its online remote monitoring capabilities with production logs and maintenance plans, as well as great process support with remote troubleshooting from a leading OEM.

Sustainability is embedded in our digital offering. Digital advantages of these tools and services provides you with benefits such as smaller energy consumption, less waste and lower CO2 emissions. Whatever the size of your operation, by combining your Metso Outotec equipment with our digital advantage and expert insight, you can squeeze the last ounce of power out of your operations – and win the race.

For more information about Metso Outotec’s digital offering go to our website.

Content produced in association with Metso Outotec