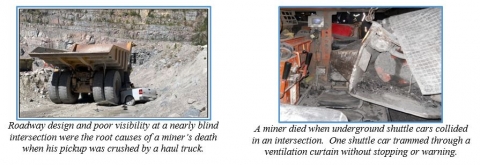

The Mine Safety and Health Administration (MSHA) has confirmed fatalities and accidents involving mobile equipment continue to occur at a disproportionate high rate.

The MSHA has issued best practices to help stop powered haulage accidents (Credit - MSHA)

The MSHA says this equipment includes shuttle cars, scoops, locomotives, front end loaders, haulage equipment, service and pickup trucks.

Best Practices:

- Know where in the workplace others are and communicate with them: use radios, mirrors, cameras, headlights, strobe warning lights, horns, and buggy-whip flags. Stay clear of mobile equipment blind spots.

- Set mobile equipment parking brakes and chock the wheels when vehicles are unattended: Don’t stand, walk or work directly downhill of parked vehicles. Stay clear of moving vehicles.

- Establish safe traffic patterns and rules: post signage, ensure rules are followed, adhere to speed limits and approach intersections with caution.

- Use proximity detection/collision avoidance systems.

- Ensure that seat belts are maintained in good condition and worn at all times.

- Ensure that conveyors are deenergised, locked, tagged and blocked against motion before removing guards or beginning work.