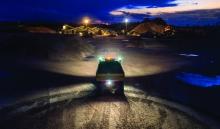

The versatility of articulated trucks, along with availability of larger machines, means they are gaining ground on rigid alternatives. Claire Symes reports

Glendinning's Linhay Hill Quarry used to operate a fleet of rigid dump trucks (RDTs), but over the last year the fleet has gradually been replaced by smaller articulated machines. The UK-based quarry operator initially trialled one 40 tonne articulated dump truck (ADT) but has now ordered a second for the site near Ashburton, Devon.

"We wanted to see if 40tonne ADTs could replace our fleet of 50tonne rigids," explained Linhay Hill Quarry supervisor Reg Perrow. "Having operated

But Linhay is not an isolated case, more and more quarries are opting for ADTs to replace RDTs because they offer greater versatility.

"RDTs are still the best for long hauls with good conditions, particularly if the material is very hard or in large blocks. The choice also depends on the material - for sand and gravel deposits which are generally lighter than blasted rock, then an ADT is better suited to the hauling task," said

Upsizing

According to

"There has been some development of 50tonne class machines -

"Nonetheless it is generally accepted that RDTs are 30% less expensive in terms of repair and maintenance. I know one operator who has replaced all of his RDTs with ADTs and is very pleased with the lower fuel costs per tonne and the higher productivity, which may be true over five to seven years but it may not be the case over a longer period." However, it is the versatility that adds to the benefits of ADTs. "They can be used at every point during the extraction process from removal of the topsoil to hauling of the aggregates and final restoration of the site," said McNeil.

Recent developments in the market have also helped to add to the versatility and one of the latest machines from Bell is a case in point. At

Technology

While ADTs are getting larger and more specialised, recent development has also helped to improve the suspension and drivelines on articulated haulers to make them more comfortable, improve efficiency and reduce wear and tear. "One of the next phases of ADT development will be the addition of new engines to meet the next stage of the emissions regulations in 2011 but there are also more developments to come in terms of making the machines more operator friendly and comfortable," said Macintyre.

"But I think it will be more a case of evolution rather than revolution for ADTs over the next few years." Some quarries have started to favour conveyors over ADTs due to the lower operational costs and need for fewer skilled operators, but Macintyre believes that the versatility of ADTs still gives them a competitive advantage. "Conveyors may provide and alternative for some quarries but ADTs offer flexibility," he said. "Conveyors have significant time and costs linked to setting them up but if there is a breakdown then it can severely impact on the whole site, whereas it is easier to cope if one ADT out of a fleet is out of action.

"The cost and time involved in moving a conveyor as extraction progresses also has a big impact on production."