This unified platform gives managers insights into job site productivity and equipment utilisation. The scalable cloud-based application collects and summarises data from any subscribed machine equipped with a Cat Product Link device, ensuring that fleets with mixed OEM equipment can seamlessly incorporate into one unified platform.

VisionLink Productivity simplifies data management with its user-friendly dashboards. These include a comprehensive job site summary and detailed insights with key performance indicators (KPIs). The platform analyses standard telematics data, such as machine location, fuel burn, and idle time, providing a clear overview of machine performance. For more in-depth analysis, advanced data from machines equipped with Cat Payload, Grade, and Compact systems provides more job-specific details.

Cat Grade and Compact

VisionLink Productivity now incorporates Cat Grade 3D and Cat Compact data into its robust reporting platform. Leveraging Cat Grade Connectivity, the platform enables 3D design files and updates to be seamlessly distributed to all machines at the job site, eliminating the need for USB uploads. VisionLink Productivity further improves accuracy through GNSS corrections for position validation rather than installing a base station with high set-up costs for short projects. Grade Connectivity also minimises machine downtime by reducing the need to send a technician onsite to diagnose Grade related issues, improving overall job site productivity.

Cat Compact summary dashboards show the amount of work completed for each day and calculate the fill volume. The Cat Compaction Algorithm (CCA) or Landfill Compaction Algorithm (LCA) will also show the percentage of the covered area at target compaction. Landfill material compaction density can be viewed when operators enter weights per day.

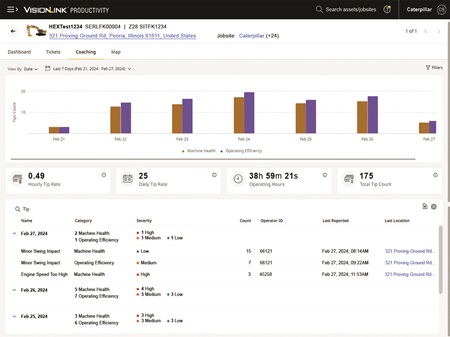

Operator Coaching

Operator Coaching is a powerful tool that empowers operators of all experience levels to enhance their skills, efficiency, and productivity. Two categories of operator coaching tips – Operating Efficiency and Machine Health – are tracked. During machine operation, the operator receives an onboard notification when an action with a corresponding tip is detected, putting them in the driver's seat of their improvement journey. This helps to improve operational efficiency and increase machine longevity.

When paired with the offboard VisionLink Productivity, managers can remotely view what coaching tips their operators have activated. This enables site managers to track improvements over time and focus training on areas specific to the operator's needs and overall operations. Dashboards, lists, and maps allow quick views of each coaching tip's count, time, and location.

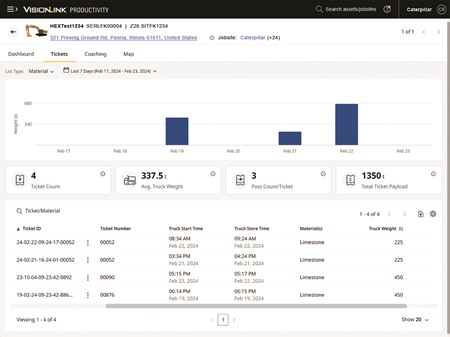

Cat Payload E-Ticketing

The new E-Ticketing feature brings convenience, eliminating the need for manual or printed tickets generated by onboard Cat Payload systems. Key personnel can now receive an electronic copy of the tickets via email, including detailed information on individual buckets, total payload, truck, and material type. Tickets can be quickly recalled using ID or number or filtering based on material type or truck name. Key performance indicators tracked by E-Ticketing include ticket count, average truck rate, pass count per ticket, and total ticket payload.

For more information about the new VisionLink Productivity features, contact a Cat dealer or visit www.cat.com.