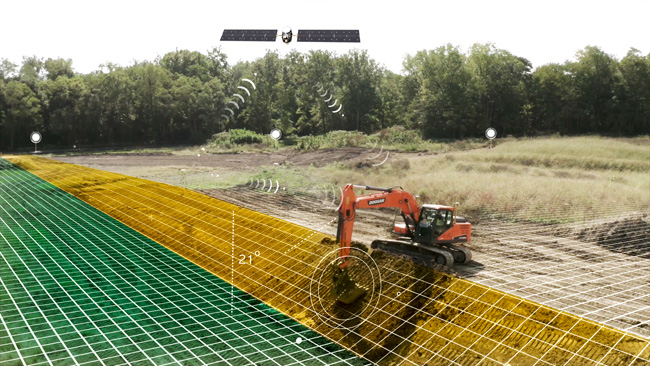

The company says that, to meet increasing demand for the greater efficiency offered by machine guidance systems on excavators, the smart solutions offering will now feature new Leica,

The new pre-installed ready kits can be ordered direct from the factory through Doosan Smart Solutions for use with Leica, Trimble and Xsite 2D and 3D machine guidance systems. Doosan also offers factory-installed SVAB/Steelwrist options for the company’s DX140W-5, DX160W-5, DX165W-5 and DX170W-5 wheeled excavators.

The company has launched a new mobile app for Apple and Android devices for the DoosanCONNECT fleet and asset management system, which now covers over 70,000 of its machines worldwide. Further support is being provided by a package programme of regular maintenance and extended warranty designed by Doosan and carried out by the service teams at its dealers.

At April's bauma show in Munich, Doosan showcased its long distance machine remote control system which uses the 5G telecommunications platform. It also previewed the ConceptX suite of digital solutions for site automation of quarrying and construction machines, including fuel cell drones and autonomous vehicles.

Doosan Infracore Europe CEO Charlie Park said that the company plans to demonstrate the ConceptX technology at an event in South Korea this November.

"It will show to customers, dealers and the market in general where Doosan is going on its product development," he added. "It will include our complete suite of solutions: control centres, cloud-based systems, digitalised machines, autonomous driving and our drones.”

Doosan claims to be the first manufacturer that has used 5G technology for worldwide ‘TeleOperation’ of construction machines. The company has coined the term TeleOperation to describe the operation of construction equipment from a remote station. At

“The construction, quarrying and mining industries are becoming increasingly digitalised,” said Park. “We want to stay ahead by investing heavily in new technology for our product development, which includes investing in our drone solutions and automated machine control. We are also partnered with many big solution providers such as Trimble, Leica, Moba (Novatron) and now Palantir.”

At bauma the company also gave a video demonstration of Doosan Mobility Innovation’s drones for monitoring and analysing machine performance and wider operation efficiency on quarry, construction and mine sites.