The Mayor of London and Transport for London (TfL) have introduced a targeted Lane Rental scheme. It allows TfL to charge companies a daily fee for undertaking roadworks on the UK capital’s busiest roads at the busiest times.

This scheme should encourage more efficient working and reduce disruption from roadworks.

One way to help minimise the amount of time that works disrupt traffic is to clarify the early-age strength requirement of concretes, and other cement bound materials, used for the reinstatement of openings in highways.

This was one aim of a project, funded by the Department for Transport (DfT) and TfL, entitled Reducing congestion from Highway Works.

It is up to highway owners and their designers to specify the compressive strength class of the concrete or other cement bound material required for reinstatement.

Using HD 27/04 it is possible to determine the minimum cube strength required from the reinstatement material to open the highway to traffic as shown in Table 1.

One of the most frequently used materials for highway reinstatement [in the UK] is a C16/20 concrete or CBGM B concrete as a base layer in a composite road. This material is usually subject to a ‘deemed to satisfy’ curing period of seven days before trafficking, and this is where there is scope to reduce the time the highway is closed for reinstatement.

From Table 1 the minimum cube strength required for a C16/20 before trafficking is 15N/mm2, deemed equivalent to a 19N/mm2 measured on laboratory cured cubes.

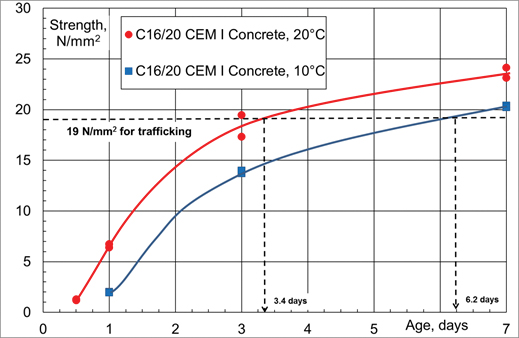

Figure 1 shows the relationship between compressive cube strength of laboratory-cured specimens of a C16/20 CEM I concrete or CBGM B with age, at both 20°C and 10°C.

The 28-day target mean strength for a C16/20 is around 30N/mm2, where with CEM I as the binder the seven-day strength is expected to be 24N/mm2. That is around 80% of the 28-day strength. Where a cement is used that includes 30% fly ash or 50% ggbs [ground granulated blast furnace slag] only around 70% of the 28-day strength is normally achieved.

Using the 20°C line from Figure 1 it is evident that a C16/20 only requires up to 3.5 days to reach the required strength, and only where the curing temperature is reduced to 10°C does the time required increase to just over six days.

| Reinstatement material | Compressive strength class *

7 day |

28 Day |

Mnimum cube strength for opening traffic †, N/mm2 | Target laboratory cube strength at opening, N/mm2 |

|---|---|---|---|---|

| Concrete | - | C32 / 40 C20 /25 |

25 20 |

32 25 |

| Concrete or Cement Bound Granular Material (CBGM) B | - | C16 / 20 C12 / 15 C8 / 10 C5 / 6 |

15 10 7 4 |

19 13 9 6 |

| Foamed concrete | C3 / 4 C1.5 / 2 |

- | 2.8 1.4 |

3.6 1.8 |

* Strength class minimum characteristic cylinder/cube strength

† Based on values given in HD 27/04

At a depth of around 1.2m the ground temperature is typically from a minimum 4°C in March to a maximum of 17°C in September. Therefore, 10°C may be considered a reasonable estimate for typically unfavourable conditions, accepting that as cement bound materials generate heat on hydration they will be warmer than the surrounding ground temperature. It may be argued that a seven-day curing period for reinstatement material is safe and may be useful guidance where there is no urgency in getting a highway back in service. Where it is important to get the highway open, to reduce congestion and save cost, then there is potential to reduce the curing period to that required to achieve the necessary in-situ strength.

As shown in the Figure 1 example the curing time could be reduced to less than four days for CEM I C16/20 under favourable conditions. In general, a practical solution is for the reinstatement contractor to adopt in-situ testing to demonstrate that the required strength has been achieved, rather than just accept overly conservative deemed-to-satisfy rules for curing time.

Further information from the Reducing Congestion from Highway Work project is available from the Transport Research Laboratory (

The author, Dr Chris A Clear, is technical director of the British Ready-Mixed Concrete Association.