The European Aggregates Association is promoting improvement of the European legislative framework to further increase the use of recycled aggregates

Recycled and secondary aggregates are making an increasingly important contribution to the aggregate demand in Europe as they work to reduce virgin extraction. However, the level of recycling, the appreciation of the recycled material and its application are significantly different in EU Member States. By transferring this recycling knowledge, it is possible to reduce demand on primary aggregates and help the industry to become more sustainable.

To address policy issues related to greater recycling of aggregates the industry is working together to create a one-voice approach. The

Between them, the two organisations represent the two broad groups into which recycled and secondary aggregates fall into - demolition and construction materials and industrial by-products such as china clay waste, power station ash (PFA), blast furnace slag from the iron and steel industries.

The mission of EPRA is to achieve the best use of recycled aggregates for the highest applications possible. The challenges to be addressed that go with recycled and secondary aggregates are of environmental, technical and economic nature and trigger some questions regarding European legislation.

Product or waste?

In several Member States recycled aggregates that meet national requirements are considered as a product and not as waste and this is something the

At European legislative level, and until the end-of-waste criteria are defined, recycled aggregates still constitute waste. The fact that some Member States do not consider it as waste does not change this situation. The European legislative status of recycled aggregates will finally become clear when end-of-waste criteria will be defined.

The UEPG is working to get clarity on the issue of the relationship between the end-of-waste status and the European Chemical Regulation REACH.

The European Commission does not consider recycled aggregates as articles under the REACH regulations. However, natural and recycled aggregates are used because of their physical properties and not for their chemical properties. The production process (crushing, screening and washing) has only one goal: namely production of a material with specific shape, size and surface characteristics. Chemical composition is not an item of interest upon validating fitness for use.

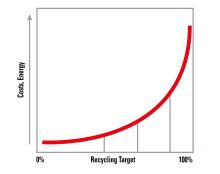

The taxation of primary aggregates can encourage increased use of recycled materials, but experience to date is that measures to restrict the landfilling of waste are more effective in encouraging recycling in aggregates markets.

To date, there is no clear case that significant levels of national aggregates taxation have contributed positively to the improvement of sustainable development. The report of the

The UEPG will continue to lobby the European policymaking process to try and ensure the technical, economic and environmental legislative framework is settled to achieve a more sustainable society.