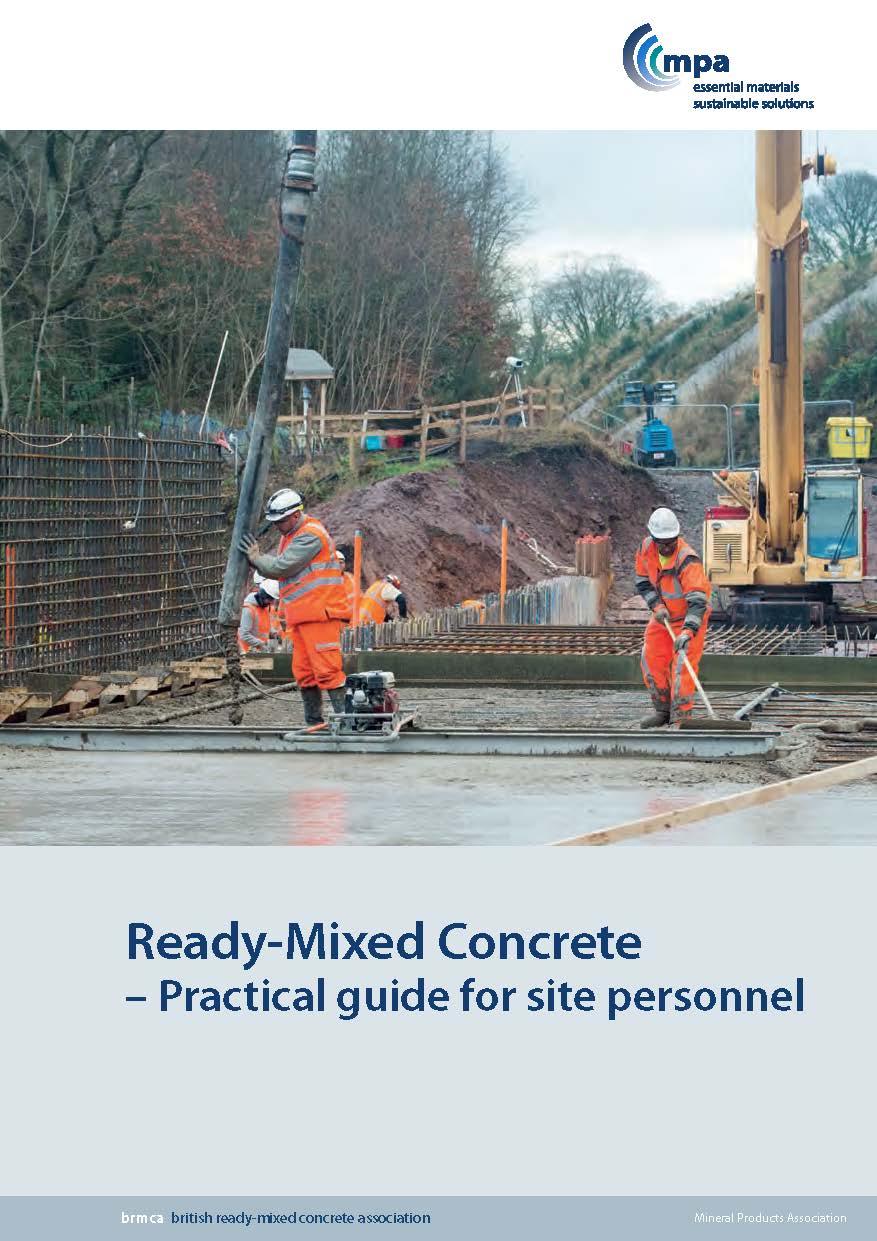

The British Ready-Mixed Concrete Association (BRMCA) has published a new practical site guide for site based employees and contractors. The pocket-sized guide contains practical guidance on how to specify, order, receive, place, compact, finish and cure ready-mixed concrete on construction sites. Guidance is also appended on sampling concrete for testing consistence and air content, and making specimens for strength for those contractors who carry out these activities on site. Construction sites present potential hazards and the guide includes easy to use information on health and safety, including how to prevent cement burns.

Chris Clear, director BRMCA, said: “Ready-mixed concrete is often taken for granted. For many contractors it is just a question of picking up the telephone and ordering whatever is listed in the project specification. However, concrete does need to be ordered correctly and placed, compacted, finished and cured properly to ensure the required performance in-situ. In addition, where site testing is specified it is necessary to follow standard procedures for sampling and testing fresh concrete as well as producing cube specimens for strength testing.”

Welcoming the guide, Steve Crompton, chairman of BRMCA, said: “This essential guide covers all aspects of ready-mixed concrete operations on construction sites from ordering, placing, compaction, finishing, curing, testing and the all-important Health & Safety aspects. It is a clear and concise document for all site based employees and contractors and also a useful teaching and learning aide. We will be distributing this energetically throughout the construction industry over the coming weeks and months”

As part of its ongoing support for ready-mixed concrete customers, BRMCA has made the guide freely available either as a download from the BRMCA website or a hard copy on request from %$Linker: