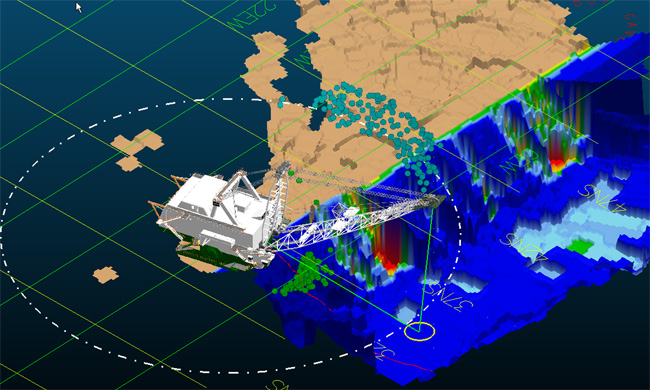

In a claimed global industry first, MineWare’s Pegasys Dragline Monitor has extended its capability to support underwater digging.

Enhanced with MineWare’s new Machine Terrain Mapping (MTM) Technology module, Pegasys can now help miners and quarrying operators locate and recover material up to 100 feet below water.

MineWare North America regional vice president Greg Ladewig said this is a significant development for the mining and quarrying industry globally, making underwater materials retrieval safer and more efficient.

“Identifying and reaching mineable material on the pit floor is a key challenge for underwater dragline digging and dredging operations,” he said.

Equipped with MineWare’s MTM technology, Pegasys addresses this issue by enabling operations to locate mineable underwater reserves that were previously out of reach.

“Miners can now get a much clearer picture of what’s beneath the surface, improving visibility, productivity and efficiency.”

Bedrock Resources was the first to adopt the technology at their limestone mining/quarrying operations in Florida, USA. The system has been in place for 11 months.

“Pegasys has provided Bedrock with a new level of situational awareness of their underwater digging conditions,” said Ladewig.

“During a two-week re-mining period, Bedrock successfully recovered approximately 49,000 additional tons of material that may have otherwise gone unrecognised.

“This technology represents a major step forward for the industry with significant potential for productivity gains in dredge mining, re-mining and the mining of flooded areas— where operations traditionally need to cease.

“These inaccessible or hard-to-reach areas are now back on the table.”

MineWare’s MTM technology has also been successfully implemented by a coal mine in South Africa.

Ladewig said the team was quick to implement the technology after substantial rain caused the coal pit to become submerged in 32 feet of water.

“Utilising Pegasys’ new capability, the mine was able to productively continue their operations with little to no downtime,” he said.

“Pegasys uses bucket position information to allow operators to mine underwater where they cannot visibly see.

“This reduces the risk to personnel and improves efficiencies, while also assisting with slope management by reducing the risk of the machine undercutting itself.

“This latest development is another example of the high degree of flexibility and interoperability built into our Pegasys system.

“We are continually working on ways to improve our technology for our customers, with practical solutions that meet common industry challenges across the mining value chain.”

Pegasys’ new underwater digging capability is now available to all existing and new Pegasys customers in global mining markets.