The innovative concrete incorporates industrial waste products such as fly ash – a by-product of coal-fired power stations. It is especially suited for construction in earthquake zones where the brittle nature of conventional concrete often leads to disastrous building collapses.

“Concrete is the most widely used construction material in the world,” says ARC DECRA Fellow at Swinburne's Centre for Smart Infrastructure and Digital Construction, Dr Nematollahi.

“In fact, it is the second-most consumed material by human beings after water. Its quality has a massive effect on the resilience of our infrastructure such as buildings, bridges and tunnels.”

Traditional concrete is not only prone to shatter when being stretched or bent, but also has a huge carbon footprint due to calcination of limestone to produce its key ingredient, cement. By using industrial waste products, Dr Nematollahi and colleagues have done away with the need for concrete, making the product more sustainable.

“Production of this novel concrete requires about 36% less energy and emits up to 76% less carbon dioxide as compared to conventional bendable concrete made of cement,” says Dr Nematollahi.

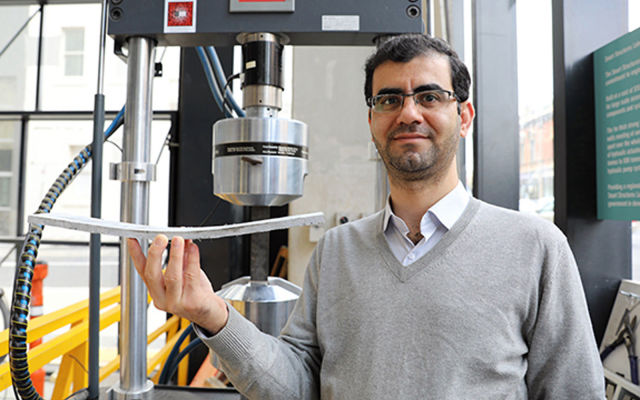

Furthermore, the inclusion of short polymeric fibres in this novel concrete allows it to sustain multiple hair-sized cracks when put under tension or bending and not break into pieces.

In fact, it is able to bend when force is applied to it – meaning that buildings made from it will be much more likely to remain intact during earthquakes, hurricanes, projectile impacts, and blasts.

“Building in areas vulnerable to that sort of natural disaster is one of the main uses that we can see for this material,” Dr Nematollahi adds. “Our laboratory test results showed that this novel concrete is about 400-times more bendable than normal concrete, yet has similar strength.”