How does Maptek see the current global surface mining sector for its product range around blast execution and analysis?

Most surface operations have piecemeal solutions to drill and blast - one system tracking drilling, another blast hole loading, another post-blast analysis, as well as ad hoc attempts to audit and analyse historical information - all in a disparate collection of paper sheets, survey data and file formats. Measurement While Drilling (MWD) systems are great, electronic firing systems are great, intentions are great, but the information cannot be cross-correlated in a timely way to be of ultimate benefit to the operation.

Maptek BlastLogic is termed a quality management system or a design and reconciliation system, and regardless of those descriptions at the end of the day, the solution provides a unified platform (one-stop-shop) for improving drill and blast.

Customers describe the value delivered through BlastLogic as providing transparency and accountability on their blast designs and how well these are executed. The combination of blast design, integration and reconciliation tools through a paperless system with near-live synchronisation is how Maptek differentiates its solution from siloed reporting mechanisms.

Reporting tools collect the data during the shift or a production cycle, bring it together and report it. By then, the shift is over, and it’s too late to apply the analysis to make informed decisions mid-shift when it can actually make a difference.

Importantly, BlastLogic delivers productivity and efficiency gains beyond the drill and blast space. Linking the performance of the blast to geology, the production plan and downstream processes add agility to planning and production. For example, integrating dig rates or vibration results means all stakeholders overseeing the safety, production and cost drivers of the mine or quarry can apply information around ‘how well that blast performed’ to the knowledge of the impact on the overall operation.

Correlating all of the blast-related data in one place and getting objective validation and analysis around that data, with results transparent to all teams in surface operations, facilitates greater coordination among functional groups. The learnings gained from analysing that data are fundamental to blast performance.

The founding premise of an all-in-one design and reconciliation package is in substantiating how well you are executing your design. Think of it as a way of measuring confidence. If you measure something, you can benchmark it because you now have a baseline that guides the metric for improvement.

Closing the feedback loop between planned outcomes and what actually happened from blast design to reconciliation provides the certainty that businesses look for.

Don’t get me wrong, trial and error still exist. No-one wants to tell their manager or shareholders that they couldn’t show where improvements were made because they weren’t tracking performance.

Analysis of the blast outcomes over time provides decision guidance on how to improve - either improve blast designs or look to the execution phase to identify where gains can be made.

What impact has COVID-19 had on market demand?

Early on with COVID-19 when customers relocated their staff away from sites or corporate head offices, it became even more important to transition to digital tracking and reconciliation systems. The single source of blast data could easily be available to everyone, regardless of where they worked.

Maptek Account enables web browser access to all Maptek software entitlements, even for customers who may work offline. In this way, blast engineers and field crews can still record, model and analyse their blast data to support the operational production cycle.

Where do you see growth coming from in your product offer to open-pit mining customers?

Tighter integration between drill and blast and other operational processes is a key consideration in the Maptek development strategy. Surface operations need a continuous feedback loop of collecting, validating and reconciling data to better manage their planning and production cycles, and allocate resources efficiently.

Field and management teams at quarries and open-pit mines are supported by the digital data flow to respond appropriately to the need for changes in real time, knowing that their decisions are founded on current information and actual conditions.

The drive for optimisation solutions, by which we mean a balance between value and practicality, is behind an ambitious new Maptek project to automate the currently intensive engineering design process.

We’re using our scalable cloud platform, the Maptek Compute Framework, to build a new blast optimisation tool. BlastMCF applies an evolutionary algorithm to handle multi-objective, many-constraint, population-based modelling. The approach has been proven in our scheduling and domain modelling solutions to generate realistic results faster than with traditional methods.

The outcome is a dramatically improved workflow for blast engineers. Instead of focusing their time coming up with one design (that may prove to be sub-optimal), they will pivot to trading off the multiple designs that are automatically prepared. Typically these are more than 90% ready to be executed, and the chosen design can still be updated manually in BlastLogic if minor tweaks are required.

What success have you had in the marketplace with your latest product solutions centred on blast execution and analysis? Can you give a couple of customer examples?

Specialists tasked with continuous improvement and innovation are typically keen to look at their mining or quarry operation holistically.

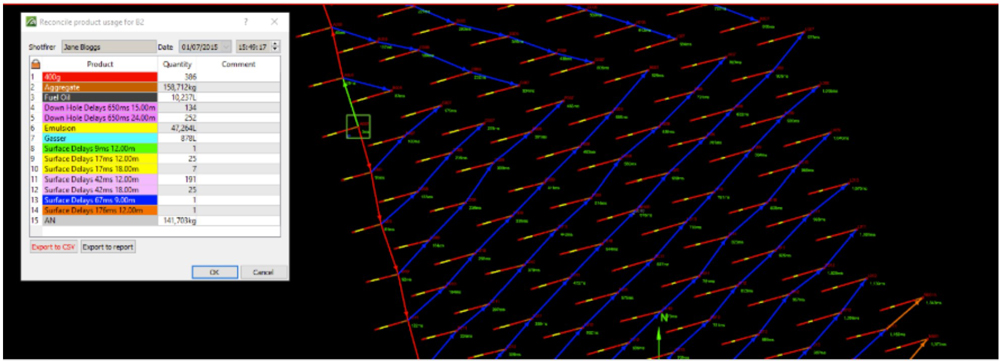

Proper explosives handling and tracking is crucial to safety and efficiency, and going digital is key to ensuring operational compliance. When stock levels can be updated dynamically in the field using the BlastLogic Tablet, potentially confusing paper-based record-keeping is eliminated, and manual calculation errors are minimised to account for all explosives used on a particular blast, or not used and returned to the magazine.

Tablet data is synchronised with the BlastLogic desktop application and central server, and reports can be created and printed for regulatory sign-offs. Live dashboards give a real-time view of inventory and allow flagging and investigation of stock discrepancies.

Digital record-keeping is secure, provides greater clarity and aligns with the industry trend for paperless operations. The BlastLogic digital workflow is helping customers reduce downtime and reap the benefits of a data-driven, decision-making approach.

Is Maptek planning to introduce any new products for surface mining sector customers in the next 12-18 months? If so, when are they likely to be made available? And crucially, how will they add to/differ from what is already on the market?

BlastMCF mentioned above is one of the key areas where automation can deliver benefits to surface operations such as open-pit mines and large quarries.

Maptek will soon introduce the ability to record as-drilled data on our tablet applications. This will benefit many operations that cannot access drill navigation technology on all their drills.

For example, contractor equipment which may not have drill navigation installed, or sensors may not be functioning correctly and awaiting repair. With BlastLogic, drill operators will be able to use the BlastLogic Tablet instead of paper plod sheets. As-drilled data like drill operator name, drill ID, drill time, depth and custom drill properties that are supported in BlastLogic will be recorded, making it immediately available to be consumed in the design-validate-reconcile feedback loop for blasting.

The recording of accurate digital data has shown to significantly improve overall performance by enabling this measurement to be used earlier in the drilling and blasting process, so re-drills and backfilling are accurately performed in time for charging.