Digital and automated technologies are continuing to change the way the quarrying and mining industries operate.

To meet these requirements Orica, a manufacturer of commercial explosives and blasting systems for quarrying and mining, says it is advancing its digital expertise and solutions.

The company has added new features to its BlastIQ solution to bring additional capabilities and help customers reduce the overall cost of quarry and mine drill and blast operations, improve operational productivity and safety, and facilitate regulatory compliance.

Orica says that improvements to the BlastIQ user interface allow real-time access to the status of each blast through the centralised online BlastIQ Platform, enabling users to collate and collaborate on data from across the drill and blast process. Insights can be interpreted from data gathered with new visualisation features, accelerating planning, analysis and auditing of blast data to satisfy regulatory requirements.

Multilingual support has also been added across the technology suite, now supporting Spanish, French Canadian, Russian and Portuguese, facilitating broader access and adoption of BlastIQ for more customers around the world.

BlastIQ Mobile technology now provides a wider set of loading conditions through the seamless integration of loading rules, increasing on-bench quality-control management and productivity. Continuous loading rules can now be applied to blast holes in real time, even in areas without bench wireless connectivity, creating efficiency and quality gains on-bench.

Accuracy and efficiency of explosives delivery are significantly enhanced through real-time synchronisation of blast-hole data between Orica's Mobile Manufacturing Unit (MMU) and BlastIQ as changes occur in both design and actual loading data. Using this data, Orica’s smart, connected delivery systems load the correct explosive type and quantity according to the original design, adjusted based on blast-hole condition measurements and the automated application of a defined set of loading rules managed by the drill and blast engineer.

The claimed industry-first, direct integration with the delivery control system automates process control thereby eliminating errors in manual product selection, process control and incorrect logging of loading actuals, as well as importantly reducing overall explosives loading times and increasing productivity on-bench.

Hole identification functionality available in both BlastIQ-enabled delivery systems and BlastIQ Mobile is said to improve in-field blast quality control and assurance. The hole position identification feature helps operators to more easily identify holes on-bench, reducing errors from potential confusion over hole identification and ensuring accurate recording of which holes have been dipped or loaded. This real-time data flow empowers rapid decision-making, such as accurately adding new holes and data as needed, improving operational efficiencies.

The new features are now available and applicable across mining and quarrying operations globally. As customers increasingly look to transform their operations with digitally connected technologies, Orica remains at the forefront of digital blasting to optimise blasting outcomes.

Orica global digital product manager Angelo Labriola describes how the company’s digital technologies are helping customers. “Every day around the world, engineers design blasts and those blast outcomes impact as much as 80% of the total mine or quarry processing costs. The process of designing blasts, adjusting designs for real conditions encountered in the field, and understanding the outcomes of blasts is a manual, time-intensive task involving multiple inputs. Optimisation efforts suffer due to lack of time and tools to support that objective in the face of daily operational demands.

“BlastIQ saves time and improves quality by automating processes across the blasting workflow. Inspired by our customers’ feedback, the latest release of BlastIQ will enable our customers to make better decisions more rapidly and deliver improved blast outcomes across their operations.

“We’re aiming to develop the most robust, most user-friendly set of digital drill and blast tools available, with easy integration across the value chain and delivery of whole of mine and quarry insights required to drive material impact for our customers.”

Maptek, which supplies 3D modelling, spatial analysis and design technology to the global mining and quarrying industries, says that its BlastLogic solution enables improved design compliance monitoring and downstream productivity optimisation across open-pit operations.

“BlastLogic is applicable to any open-cut operation that conducts drill & blast and processes the output in plant or mill,” according to a spokesperson for Maptek.

The company says that, for mine and quarry operators, quantifying fundamental design parameters can highlight significant variability in the effectiveness of design execution. Once anomalies and non-compliance issues have been identified, operators can look to the cause and focus on improved accountability around performance. It also helps operators better define the practical tolerances for execution of blast for their operation.

The drill and blast process typically equates to 20% of mining extraction cost per tonne and Maptek says there are significant opportunities for improvement and cost reduction. “In practice this could mean developing effective designs that align drill pattern, charge and tie-up plans to the specific mining conditions and measuring their successful execution,” the company comments.

Because blast performance is directly impacted by compliance to design, operators need tools to help them routinely and reliably measure the effectiveness of designs. The difficulty has occurred where insufficient information exists, or where the information exists but is not readily reconciled.

Measuring and tracking blast designs against defined tolerances during execution can therefore quantify the variability and facilitate objective assessments.

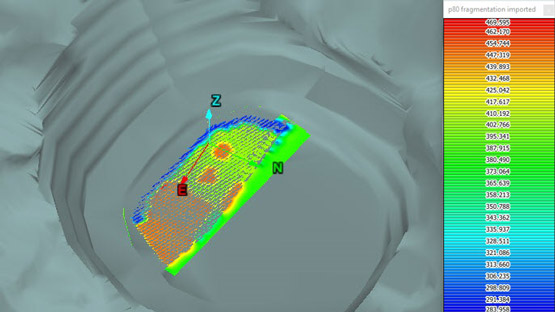

BlastLogic is designed to provide a platform where all an operation’s drill & blast data is stored in a single repository for analysis. Operators can then derive additional value from blasting practices, enabling opportunities through pattern expansion, steeper pit slopes, grade engineering and improved mine-to-mill practices such as fragmentation analysis.

Better fragmentation has been linked to a shovel improvement of more than 9%. Achieving optimal and consistent fragmentation improves ‘digability’ through easier handling and processing of excavated material. By looking at the broader picture of the entire comminution process, BlastLogic is designed to provide the means to measure and track drill and blast performance relative to crusher and milling throughput.

Maptek says that geo-referenced spatial data imported into the BlastLogic drill & blast management solution delivers greater understanding of blast execution and results, enabling future blasts to be refined and optimised to reduce costs and increase safety and productivity.

South African surface mining industry association Aspasa is extending its strategic service to members in the form of a new blasting audit.

According to director, Nico Pienaar, Aspasa has decided to offer blasting audits to members due to its mining industry facing numerous practical-legal challenges since the Mine Health and Safety Act’s (MHSA) new explosives regulations came into effect on 14 December 2018. He adds that there have also been various demands made by affected communities and Department of Mineral Resources (DMR) officials.

“Whilst some of these demands are not provided for in legislation and others are simply impractical, they are having an impact on the running of mining operations,” said Pienaar. “A blasting audit that’s in line with all new requirements of the MHSA is a positive step toward clarifying and endorsing the legal parameters of mining operations, and particularly when it comes to the use of explosives.”

To develop the audit, Aspasa has tasked an explosives solutions company that manages explosives-related legal challenges, blasting engineering improvement initiatives, and independent investigations to undertake audits of members sites.

Whilst the audit’s objective is primarily to prevent explosives-related incidents, accidents and legal stoppages, Aspasa says it does employ a more comprehensive examination.

It adds that the audit basically covers operational-legal compliance with the Explosives Act and with MHSA explosives regulations.

It also covers regulations relevant to licenses, permits, approvals, etc; operational implemented systems, measures, procedures and risk assessments; and physical inspection of explosives facilities and blasting processes.

Aspasa says the audit’s management strategy will achieve its objectives through focusing on the following main areas of the audited mining operation: its explosives responsibility structure; an evaluation of its explosives technology; an assessment of product requirements and supplier contracts; and explosives quality control and quality assurance.

In addition, mining operations will receive advice and assistance regarding various explosives-related challenges such as legal stoppages, complaints from the public related to blasting (whether caused by vibrations, noise, dust or debris), independent investigations into explosives-related accidents or incidents, and applications to the DMR.

Aspasa says that the aim is to provide all its members with a highly relevant service at an affordable cost. This service includes the formal audit submitted to the mining operation, detailed feedback on all areas of non-compliance, and recommendations to ensure compliance.

According to Pienaar, the audit functions on the same basis as Aspasa’s health, safety and environment audits.

“The blasting audit’s cost is a fixed fee that’s in line with the other audits,” he said. “Unfortunately, non-Aspasa members don’t qualify for this special fee, as well as members who are not paid up to date.”

Pienaar emphasised that this new service to Aspasa members is a crucial step toward ensuring mining operations function well within the law.

“Not only will the law be complied with, communities will be shown that the operation adheres to legislation, and DMR officials can be made to understand the specific mining operation is progressive in its compliancy,” he said.

EPC Groupe, which supplies explosives and drilling and blasting services, says it is striving to digitalise the entire quarry environment, helping to create a more integrated, seamless and safer approach to blasting and drilling. With these objectives in mind, it has recently focused on several innovations - including Expertir, Expertab and EPC Metrics – which are designed to turn its vision into reality.

Expertir is a software application designed in-house by the EPC Groupe. It combines surveying with blast creation and is designed to remove the need for separate processes and applications to be performed and therefore provide a coherent, unified system.

Creating a 3D site map, Expertir allows engineers to “walk around” a quarry and create 3D models of planned blasts. Blast designs can be sent directly to the bulk truck and drill rig, and initiation patterns can be conveyed to the electronic detonator.

Back on the field, the operators handle all critical information calculated by Expertir on their GPS-based Expertab, which in turn interacts with the programmable logic controller (PLC) to implement the right quantity of emulsion in the right hole.

EPC Metrics is a comprehensive online blast-monitoring service for the remote assessment of vibration and air over-pressure. Designed to facilitate the immediate access of event data via fixed monitoring stations, EPC says the system eliminates the need to travel to a monitoring location and the time-consuming manual process of downloading results in the field.

With a fleet of drones already in use, EPC Groupe has performed a series of trials to assess the accuracy of drone-profile measurement compared to more conventional face-profiling methods. The company says it became clear by acquiring blast imagery from the vantage points drone technology offered that more precise modelling of blast faces could be achieved. The entire process, from flying the drone to processing the resulting imagery, takes no longer than 30 minutes and EPC says it has proved to be a more efficient method of modelling compared to more conventional face-profiling methods.

Twenty fully trained drone pilots from across the EPC Groupe now use drone technology, in conjunction with photogrammetric techniques coupled with a photo overlay, to enable them to create highly accurate models which illustrate blast faces in incredible detail.

Expertir and EPC Metrics can combine with other technologies, such as EPC’s drone fleet and Smart Rig, incorporating automation and GPS technology to create a fully integrated, digitised, 360° blasting and drilling solution.

EPC Groupe says that managing the drill and blast process safely, with accuracy and performance from beginning to end, is its constant objective. To achieve this, the company has developed a suite of digital solutions which gather and analyse data from every stage of the drilling and blasting process. The EPC Platform, which is currently under development, aims to bring all this information together in one place, enabling users to analyse and evaluate data from throughout the extraction process.

“EPC Groupe is continually investing in the future to ensure its technologies and engineering expertise are industry-leading,” said Ian Davies, general manager, explosives and blasting at EPC-UK. “Our ongoing digital developments, the expansion of our drone fleet and our new Smart Rig, demonstrate our commitment to providing our customers with only the most up-to-the-minute drilling and blasting technology.”