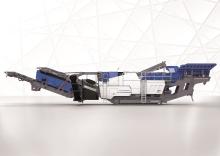

A key component in Feess overall recycling process chain is the MOBIREX PRO MR 130i mobile impact crusher. The company tested the plant at the end of the development phase and was so impressed that it decided to keep it. Upgraded to serial production standard, the plant now plays an important role in Feess' climate-friendly production.

Feess CEO Walter Feess said: "Construction and demolition wastes are a huge factor in the overall volume of waste generated – they make up over 50 per cent of the total waste produced in Germany! At present, high-quality mineral construction resources are dumped in landfill sites every day or are at most utilised as materials for sub-bases or filling. This is an incredible waste of valuable resources that we are making every effort to prevent. We return large amounts of construction materials to the cycle and use them, for example, to produce R concrete aggregate.

"With the MOBIREX MR 130i PRO mobile impact crusher, we process concrete demolition material and mixed rubble to produce materials such as mineral aggregates for R concrete. Around 40 per cent of recycled aggregates can be added to concrete without any disadvantages with respect to processing, appearance, haptics and strength. Unfortunately, the material is currently rarely used by architects and civil engineers – simply because it is still relatively unknown. Changing this situation is one of the points we focus on in our training centre: We want to make professional users aware of the quality of R concrete and the amazing opportunities it offers. Not to mention the enormous reductions of CO₂ emissions it makes possible, with which we make an important contribution to the fight against climate change."

Feess says It's clear that society has to "act now" on protecting our environment. "There is no point in merely talking about having to get a grip on CO₂ emissions. We owe it to our children and grandchildren to take action now and create corresponding legal and normative bases. But the great thing is that: We already have the capabilities, the technology and the expertise – all we have to do is use them. With this in mind I have actually set my sights on the more ambitious goal and will never tire of appealing not only to architects and engineers, but also to local authorities and administrative bodies. As a recycling company, for example, it is incredibly difficult to get the space we need. Short paths in the materials recycling process would enable us to significantly reduce long transport distances and the associated CO₂ emissions."

Feess says his company was awarded the contract for the deconstruction of a district administration office in the region. On that project, Feess was able to return over 90 per cent of the materials to the construction cycle. More specifically, this meant that the aggregate for the R concrete for the new district administration office was produced from the construction materials reclaimed from the old building.

"In other words, we turned old into new! The largest proportion of the mineral construction materials was crushed directly on the construction site or at our recycling depots at a rate of up to 1,800 tonnes a day. The experience we gathered here is something I'd like to share, including with our competitors. The change can only happen if we all pull together. Apart from that, this procedure is not necessarily more expensive. Fuel and material prices will continue to increase due to scarcity and the CO₂ tax. Therefore, recycling processes will also have financial benefits in the long run. To me, it is perfectly clear that we will not be able to achieve our environmental goals without a narrower focus on the establishment of strong recycling management."

Feess says the overall concept of the Kleemann MOBIREX MR 130i PRO plant appealed to him and his team right away. "The low fuel consumption, the high output and the extremely efficient double-deck post screening unit. Space is at a premium here, and with this plant we get two machines in one. We used to use a crushing plant followed by a separate screening plant - now, thanks to the high performance and the ability to discharge two classified final products, the MR 130i PRO is just what we need. It also means that we now only have to operate, service and refuel one machine in our daily routine.

"For us, the plant is an extremely important component in the concrete demolition rubble processing chain. Up to now, we had one Kleemann impact crusher in operation. We used the smaller MOBIREX MR 130i EVO2 together with a separate screening plant. We still use the MR 130i EVO2, sometimes on the actual project sites. The compatibility of the parts is a practical aspect that makes it easier for us to store and organise the spare and wear parts we need.

"The fuel consumption of the new MR 130i PRO is about the same as that of the MR 130 EVO2 we were using before. However, in the past, we had to refuel the screening plant as well. That meant another 14 to 16 litres of fuel. Today, we no longer need this extra fuel. And that's not all: the MR 130i PRO brings us up to 20% higher output, which is pretty amazing when you consider its fuel consumption. The plant is also equipped with wind sifters, which help us to assure our product quality. We are currently in the process of fine-tuning the settings of the wind sifters to meet the needs of our process."

Feess syas that thanks to its low fuel consumption, the MR 130i PRO already fits "very nicely" into the company's overall concept. He says the new setup is saving the company 14 to 16 litres of fuel a day, ensuring a massive reduction of many production tonnes of CO₂. "The option for operating the plant with electric power was a decisive factor for us," continues Feess. "However, for this purpose we have to expand our transformer station, i.e. the power supply. We are already discussing a number of ideas for the realisation of this. We are also considering expanding the overall area of our photovoltaic power generation systems. It would be great if we could run the plant at least to some extent with electricity from our own renewable energy sources."

Feess' Kleemann plant operator Waldemar Rollheiser said: "All things considered, we are very satisfied with the output and the final product quality. We use both screen decks and produce a range of end products with grain sizes from 0-2 mm to 2-16 mm. The control system is also very intuitive and easy to use. In the morning I set the plant via SPECTIVE, I can then monitor the current operation from anywhere on site via SPECTIVE CONNECT. I always have an eye on the fuel consumption and also the crusher filling level. This is very useful and saves many trips. And SPECTIVE CONNECT also helps me to optimise my process. For instance, we installed belt scales on all our discharge conveyors. Thanks to this, I can now directly view the output on the respective conveyor in SPECTIVE CONNECT. If, for example, the oversize grain increases, it tells me that I need to take a closer look at the process and my settings."

Walter Feess concluded: "We are pleased to have Kleemann and Wirtgen Germany at our side as partners who pursue the same objectives as we do: counteracting climate change and doing so in an ecologically and economically meaningful manner.