Among global leaders in the design and distribution of equipment used in the quarrying, port handling, and recycling industries, Northern Ireland-headquartered EDGE Innovate stresses the EDGE SCREENPRO S18's high production rates and precision screening.

The dynamic 18’x6’ (5.4x1.75m) two-deck screen of the EDGE SCREENPRO S18 features interchangeable flip flow and conventional scalper screens, providing unprecedented flexibility. A highly versatile screening solution, the new SCREENPRO S18 is designed to process the most difficult and demanding applications, including aggregate, construction waste, sand and gravel, soils, and organic materials. With numerous screen media options and configurations available, the EDGE S18 can be used as a stand-alone unit or, if needed, placed before or after a primary crusher.

Impressive design features include a low-level feed hopper, a 2- or 3-way split configuration, hydraulic folding discharge conveyors to facilitate the quick transition from operation to transport, and a fully integrated power unit with large service access. A user-friendly control system with sequential start/stop functionality provides exceptional operational performance and unit safety.

Offering the largest hopper capacity in its class, the EDGE SCREENPRO S18 encompasses a 1400mm (55”) wide, variable speed feeder with forward/reverse functionality. A large feed opening ensures the optimum material flow to the scalping screen. EDGE’s intelligent load management system constantly monitors conveyor load pressures. It regulates feeder speed, resulting in superior uptime by eliminating material overload and ensuring optimum screening production at any given time. Hydraulic folding hopper extensions allow for side loading, while a folding hopper rear door provides further loading flexibility.

At the heart of the SCREENPRO S18 is an EDGE-designed high-stroke scalping screen with a screening area of up to 18.3m² (21.7yds²) and a wide variable working angle to suit an array of applications. The aggressive high stroke action results in superior material separation and a generous screening area ensures precision fines separation. To ensure minimal downtime, the screenbox encompasses hydraulic lift-up functionality for a quick and efficient mesh exchange process, supported by full-access walkways on both sides of the screen.

Customers can choose from a wide range of screen media options, including woven mesh, punch plate, finger screens, and before (grizzly) decks, to achieve a variety of final grain sizes and process different feed materials.

Adding to the versatility of this new SCREENPRO range is its ability to interchange the highly aggressive scalping screen with EDGE Innovate’s award-winning flip flow screen. This flexibility, combined with numerous screen media options and configurations, allows the EDGE SCREENPRO S18 to process a wide range of materials and tackle screening applications that other conventional screens cannot, such as incinerator slag or wet, damp, and sticky material.

The side discharge conveyors offer market-leading belt widths and discharge heights, but setting them up takes minutes. Thanks to an intuitive design, the plant is fully customisable both in the field and from the factory, with side conveyors that can be reversed or discharged on the same side or converted to a two-way split without any additional parts required. Unlike competing models, the SCREENPRO S18 can be road transported in these set-up modes.

To meet the demands of recycling applications, the SCREENPRO S18 can be equipped with both over-band magnets and magnetic head drums to extract and recover ferrous metals.

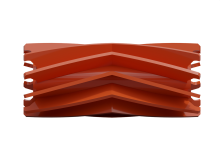

The oversize discharge conveyor features a heavy-duty 1600mm (63”) chevron belt as standard. A combination of impact bars and rollers absorbs the impact from loading material, thus prolonging the life of the conveyor belt. The oversize discharge conveyor can be lowered to 5° to provide superior access to the lower screen deck and aid in the screen media exchange process.

The EDGE SCREENPRO S18 also offers added remote functionality for improved operator efficiency and safety. All major functions on the S18, including tracking, feed conveyor speed adjustment, sequential start-up, and hopper jacklegs, can be remotely operated from a safe distance of up to 100m or in the comfort of the operator’s cabin.

Powered by either a Caterpillar or Cummins Tier 4 Final / Stage V ACERT engine ensures the SCREENPRO S18 drive system provides the operator with a reliable, durable and fuel-efficient screening solution. An electric hybrid option further enhances cost savings and environmental benefits, combining the advantages of an electric power unit with traditional diesel/hydraulic power. Utilising a small onboard diesel engine for tracking and set-up, operators can then connect to an external electricity supply once the machine is in position.

Tom Connolly, EDGE Innovate global sales manager, said: "The EDGE SCREENPRO S18 is a highly functional, reliable, efficient and easy-to-operate versatile machine that perfectly complements our other products and will serve to further raise and enhance the profile of the EDGE Innovate brand in the years ahead.”

For more information on EDGE’s new mobile scalper screen, visit www.edgeinnovate.com.