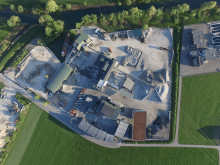

Founded in 1971, Dansand, then owner of several gravel pits, quickly became the leading supplier of silica sand to the Danish foundry industry thanks to its quartz-rich deposit in Addit. From this base, the company expanded its expertise in silica sand-based products to meet the specific requirements of the wider concrete and mortar industries.

Today, Dansand extracts and produces over 500,000 tonnes of refined silica sand in more than 20 different blends every year, supplying the construction sector, various types of industries, sports facilities, playgrounds and the DIY markets.

After more than five decades of operation, Dansand, owned by PKB Holdings and Sibelco, the world’s largest supplier of minerals, has now reached groundwater level at its pit in Addit.

The company has historically extracted material using wheel loaders, but a new approach is now required, says Claus Arve, technical manager at Dansand.

“This has been our primary means for extracting sand; however, now that we have reached groundwater level, we need to transition to dredging to ensure we can continue extraction activities. This presents a new set of challenges for our operation, and it’s for this reason that we’ve partnered with the team at CDE to engineer an efficient, high-accuracy solution that can recover valuable fractions of very fine dredged sand from large volumes of water.”

CDE business development manager Allan Esmann says while similar technologies are successfully operating in other regions, the dredge-fed wash plant will be the first of its kind commissioned by CDE in Europe.

“As Dansand commences dredging, it becomes necessary to separate dredged sand from groundwater before it can be cleaned of lignite and silt or clay fraction and then correctly sized. Central to achieving this will be our EvoWash ultra-fines recovery system with optimised hydrocyclone technology, proven to recover every valuable grain and eliminate the loss of quality fines. What makes this particular system unique is the custom cyclone composition needed to ensure Dansand continues to manufacture its very large product suite without compromising on the quality of various end products.”

The plant will be operational in early 2024.