With a 272tonnes/hour throughput capacity, the Alliance Low Water Washer accepts a dry feed from the crushing circuit. An agitator converts the material to a slurry before an integrated dewatering screen removes excess water, leaving as little as 8% moisture in the discharged manufactured sand. Superior says existing units have required as little 45-90m³/hour of water, depending on production rates. That’s significantly less water consumption than a traditional screw or cyclone.

In addition to wet processing equipment, Superior is planning to showcase a group of conveyor components.

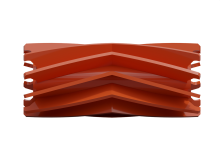

Invented by Superior in 2007, the Chevron Pulley is a novel v-shaped wing pulley deflects oncoming rocks and other material, preventing it trapping between the pulley’s wings. No rocks in your pulleys means longer lasting conveyor belts and pulleys.

Made from a composite blend, Moxie Roll is steel alternative idler that sheds sticky material to maintain properly tracked conveyor belts. The rolls are said to be 50% lighter and at least three times quieter than steel.

The High-Performance DT Idler offers improved performance in high capacity applications. The product’s double tube design features inner and outer tube construction for increased rigidly and better bearing insulation.

Finally, Exterra SFL Dual Belt Cleaner is a claimed one-of-a-kind conveyor belt cleaning solution is a primary and secondary scraper sharing one mounting pole. This allows for quick, uncomplicated installation.