Cummins is continuing its commitment to helping customers navigate their energy transitions under the leadership of Beau Lintereur, its recently appointed off-highway engine business executive director. He spoke with Guy Woodford about Cummins' progress towards Destination Zero: its strategy to reduce its products' greenhouse gas and air quality impacts further and faster. He also highlighted what quarrying and heavy construction customers can expect to see from the US-headquartered off-highway power solutions giant in 2024 and beyond.

Quarries will feature hydrogen fuel cell- and internal combustion engine-powered machines before 2030, says Beau Lintereur. "I don't think quarries will be the lead market on this, but that timescale is very realistic. It will happen first in the larger markets, like the US, Japan and Korea, with larger companies that will attract investment to make the technology cost-effective, with the infrastructure to support it."

Lintereur manages Cummins' construction, agriculture and industrial segments and global OEM (original equipment manufacturer) customers, having succeeded Eric Neal as off-highway engine business executive director in August 2023 after Neal took on a new role leading Cummins' new product introduction programmes developing the next-generation combustion engines.

Possessing extensive experience with the global power and technology leader whom he joined in 1998, Lintereur took on his new senior executive role after heading up Cummins' Mining and Aftermarket businesses for Power Systems. He has also held roles in the Power Electronics, global transfer switch, Power Generation, and Filtration businesses, including overseas assignments in China and India.

Lintereur explains that Cummins is focused on advancing its internal combustion engine technology while reducing carbon emissions without impacting operations, weight, or uptime as part of its Destination Zero strategy. Simultaneously, Accelera, Cummins' zero-emission technology brand, is focused on developing battery-electric and fuel-cell powertrain solutions and electrolysers for green hydrogen production.

"We're trying to create a bridge from where we are today to lower emissions globally. We're taking our existing knowledge, technology and history with the internal combustion engine and double downing on that," explains Lintereur. "We are doing that as we know there are not only more traditional emissions [regulations] coming, and it gives us a bridge to alternative fuels like natural gas and hydrogen internal combustion. We feel we need, essentially, a clean sheet engine design to do all those things. We are making the biggest investment I've seen in my career in new engine designs that cover the range we're talking about."

Lintereur says Cummins' variety of 'bridge' power solution options emphasises how the company intends to be with customers "every step of the way", helping them navigate the energy transition. "In mining, we are the independent power guys in every market. We saw many things and talked to everybody, and it was not certain that one magical technology would emerge to replace diesel. Diesel is this power solution that works above ground, below ground, at altitude, in this and that application, in big and small trucks, and on- and off-highway.

"I think [power solution] technology will fork and be based on application, fuel availability, infrastructure availability, and government policy and incentives. There won't be a one-size-fits-all technology. Cummins is not saying, 'This is the answer; it has to be this'."

Cummins' European Technical Centre in Darlington, northeast England, is leading the way in developing a hydrogen-fuelled internal combustion engine (H2-ICE).

The UK government-backed Brunel Project, named after another pioneer of the modern industrial age, Isambard Kingdom Brunel, has received funding of £14.6 million through the UK's Advanced Propulsion Centre's Collaborative R&D competition, which backs businesses developing innovative automotive technology.

Tests are underway on a medium-duty Cummins 6.7-litre and a heavy-duty 15-litre engine to help decarbonise commercial vehicles and construction equipment.

The Brunel Project dovetails perfectly with plans to turn the Tees Valley into a Transport Hydrogen Hub, the first of its kind in the UK.

Lintereur notes that Cummins has been an integral part of Darlington and the northeast of England for almost 60 years, with the site home to around 1,800 employees and servicing over 200 customers across more than 40 countries. "The international reach of the site is set to continue in 2024, with the launch of a new Powertrain Test Facility, which will help accelerate the move towards cleaner power energies focused on reducing greenhouse gas emissions and improving air quality.

"The facility is already leading in advancements in hydrogen internal combustion engine (ICE) technology, with the development of Cummins engines as part of the fuel-agnostic engine range. Cummins is evolving its capabilities and pushing innovation in hydrogen technology more widely with significant research and development. As part of this, Cummins' European Technical Centre in Darlington continues to oversee a consortium of leading sub-system manufacturers in the UK to achieve commercial viability for hydrogen internal combustion engines."

Lintereur stresses the need to commit resources to further developing technologies like hydrogen combustion in Darlington, which can support industries' essential decarbonisation whilst creating valuable employment in engineering.

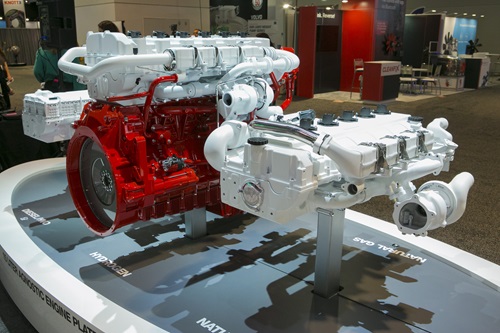

At CONEXPO/CON-AGG 2023 in Las Vegas [14-18 March], Cummins showcased its new fuel-agnostic 15-litre engine platform with hydrogen, natural gas and advanced diesel engines. It offers OEMs the opportunity to accelerate the decarbonisation of heavy-duty off-highway applications.

This new platform, designed for the next level of emissions, is said by Cummins to significantly increase power density with a more compact installation envelope, enabling OEMs to increase machine capability and productivity without impacting running costs.

The fuel-agnostic architecture of the 15-litre next-generation engine utilises a common base engine with cylinder heads and fuel systems specifically tailored for hydrogen, natural gas, diesel and biofuels, including HVO [hydrotreated vegetable oil].

The 15-litre hydrogen engine will be available with ratings from 400-to-530hp and a peak torque of 2600Nm. For applications powered by renewable biogas, this engine will offer ratings from 400 to 510hp with a peak torque of 2500 Nm available. The advanced diesel version features a broad power range of 450-to-650hp with an impressive 3200Nm peak torque.

"The platform appeals to OEMs who want to work with a technology provider that can allow them to engineer a solution for customers wanting different power solutions for their applications, be it diesel, natural gas, or hydrogen. It exemplifies how Cummins has adopted the right strategy," says Lintereur.

The big Las Vegas off-highway industry showpiece event also saw Accelera showcase its next-generation fuel cell engine, which suits heavy-duty off-highway applications' duty cycle, performance, and packaging requirements. Available in 150kW and 300kW fuel-cell engine configurations, it incorporates variable pressure technology, which provides improved power density, efficiency, and durability, all while delivering a lower total cost of ownership.

Less than three weeks after CONEXPO/CON-AGG 2023, Cummins welcomed US President Joe Biden, Minnesota Governor Tim Walz, Democratic Members of Congress from Minnesota, and local Twin Cities community leaders to its Fridley, Minnesota plant.

The Biden Administration scheduled the visit to showcase how investments in the Bipartisan Infrastructure Law (BIL) and Inflation Reduction Act (IRA) benefit American manufacturing jobs. Cummins supported the bills through the legislative process and worked closely with the White House and Congress to champion them. President Biden and other special guests' visit included a plant tour and interactions with many Cummins Fridley employees.

Timed to coincide with the event, Cummins announced that in addition to recent investments in Fridley, the company is investing more than $1 billion across its US engine manufacturing network in Indiana, North Carolina and New York.

In October 2022, just two months after President Biden signed the Inflation Reduction Act, Cummins announced it would begin manufacturing electrolysers in the US for the first time at its Fridley location. An 89,000 sq. ft. area will be dedicated to Accelera electrolyser manufacturing.

Electrolysers help produce clean hydrogen essential for reducing emissions and creating good-paying jobs in manufacturing and industrial sectors. At the same time, they play a critical role in clean energy supply chains that, until now, have largely been produced overseas.

"It was great that our work on alternative power solutions was recognised at the highest level of the US government, with President Biden visiting our Fridley plant. We are actively harnessing {US government, green energy] incentives," says Lintereur. "Our pipeline of projects on the electrolyser side is the biggest and most exciting piece on Accelera's current work, as you need green hydrogen to power anything like a fuel cell power solution or hydrogen internal combustion engine."

Lintereur says from an off-highway perspective, its mining, quarrying and construction machine customers, especially larger company or group customers, who have ambitious ESG [Environmental, Social and Corporate Governance] agendas that are increasingly keen on adopting alternative power solutions, rather than its being new government legislation and incentives-led.

"In mining, for example, achieving the lowest cost of production is the goal. Now, though, it is achieving the sustainable lowest cost of production. However, no one wants to go backwards, saying, 'I want to increase my cost of production to lower my carbon emissions'. That's where it gets tricky for them, and that is why they are pushing us and others and saying, 'Give me a sustainable [alternative power] solution that makes economic sense'. That solution will vary between customers, so Cummins' approach is right."

Is Lintereur applying key takeaways from his extensive experience in the mining equipment industry to his work as Cummins' off-highway engine business executive director? "One would be an obsession with finding a solution to the problem the end customer is trying to solve. With mining, you get a great appreciation of what it takes to successfully run a site. Part of this is the criticality of customer support. It's not just about having a solution that mathematically supplies good economics. Mining machines are complex and run in difficult environments for long duty cycles. The cost of downtime for these customers is huge. It's not so much about being issue-free. It's about what you can do to insulate the customer from pain by making their equipment run as best as it can."

In September 2023, Accelera revealed it was partnering with Daimler Trucks & Buses US and PACCAR to start battery cell production and a battery supply chain in the US.

Accelera, Daimler Truck, and PACCAR will each own and control 30% of the joint venture.

Chinese battery maker EVE Energy, set up in 2021, will have a 10% ownership and contribute its battery cell design and manufacturing know-how. EVE Energy is a major manufacturer of LFP battery cells for the vehicle industry and is publicly traded on the Shenzhen stock exchange in China.

The transaction is subject to customary closing conditions and receipt of applicable merger control and regulatory approvals, including submitting a voluntary notice to the Committee on Foreign Investment in the US.

The planned joint venture will manufacture battery cells for electric commercial vehicles and industrial applications, creating attractive US manufacturing jobs in the growing clean technology sector. Total investment is expected to be between US$2-3 billion for the plant, which will have an annual production capacity of 21GWh. It will focus initially on the lithium-iron-phosphate (LFP) battery technology family for commercial battery-electric trucks.

"This is a massive investment by Cummins and its partners, around $1 billion each," stresses Lintereur. "The first applications involving the US-manufactured battery cells will be in the on-highway space. Creating the infrastructure to support battery cell-powered vehicles, like battery charging stations, will be huge.

"With hydrogen fuel cell and internal combustion engines, we have to get the manufacturing and supply chain scale right for the on-highway industry before replicating it in the off-highway industry."

Turning to electric-powered off-highway machines, including diesel-electric hybrid and fully-electric crushing, screening, loading and hauling models found in quarries, Lintereur says: "You will see more Cummins' investments in the untethered, electric mobility side of things for both on- and off-highway, including electric drivetrains, alternative power, battery storage, and battery management systems.

"From a quarrying perspective, you may have one excavator at the quarry face feeding multiple haul trucks. You can't put an electric cable on all those trucks, so they're untethered. However, given the power requirement and the long duty cycle of those trucks, there are no batteries that wouldn't increase your payload to such an extent that it made economic sense to use them."

In addition to a B.S. in Aeronautical and Astronautical Engineering from Purdue University and an M.S. in the same field from MIT, Lintereur also has an M.S. in Management and a certificate in Public Management Policy from Stanford University.

I ask if his aeronautical and astronautical engineering expertise can be useful in his senior role with Cummins. "I was recently at the Agritechnica show [12-18 November 2023} in Hanover, Germany, talking about my engineering background with some agriculture guys. I had my team with me, and I turned to them and said, "Hey. If you want a farm on Mars, I'm your guy!'.

"Jokes aside, there are a couple of things. When you think about aeronautical and astronautical engineering, it's fundamentally a multi-disciplinary engineering field that applies that knowledge to air and space. You need to know about structures, propulsion systems, controls and dynamics. It's not like electrical and chemical engineering, for example, which are very specific. Being trained in a multi-disciplinary engineering field helps me examine problems in my Cummins work. It's about looking at the engine, transmission, controls and integration system rather than just the engine.

"The second way my background helps me is that with aeronautical and astronautical engineering, particularly on the space side, you often deal with things you cannot see. I worked on billion-dollar-plus military base systems and had to solve associated engineering problems. Thinking through and solving problems you can't see is a great challenge. I think there's a connection with Cummins' approach to Destination Zero. We must imagine the work site infrastructure, how [off-highway] applications will be done, and how we can best help customers with our power solution options."