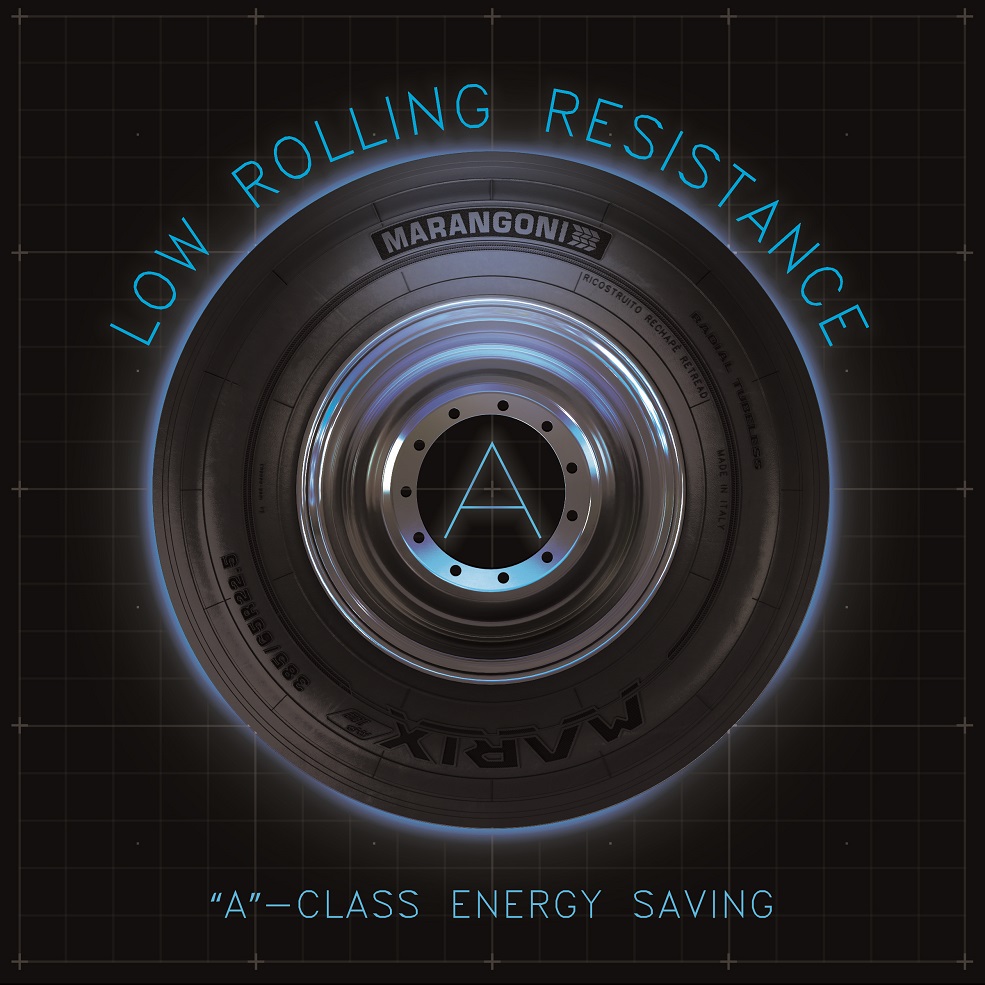

The Italy-based off-road tyre retread specialist says the result was achieved by applying a Blackline tread ring with an optimised design for low rolling resistance on a high quality casing, adding that the tyre already featured the best rolling resistance class in its first life.

Retreading took place at Marangoni's plant in Rovereto, where the group’s headquarters and R&D centre are also located.

The ring used for the test was manufactured by Marangoni using a special compound created ad hoc for the occasion. This pivotal element, combined with the specific performance features of the Blackline RTL FE tread pattern and the peculiarities offered by the Ringtread System (first and foremost no splices and no structural deformation), made it possible to create a retreaded tyre capable of achieving “A” class rolling resistance according to the same standards used for new tyres.

Marangoni says the result of the test, carried out by the independent test laboratory Prüflabor Nord, has met with a very positive response from industry experts, as few new tyres can boast such a satisfactory result.

Marangoni Group chairman Vittorio Marangoni stated: “This important achievement demonstrates our ongoing commitment to providing innovative solutions that curb environmental impact, even in the use phase, without undermining performance. It is further evidence that by implementing high quality standards, the retreaded tyre can perform at the level of the best new tyres."