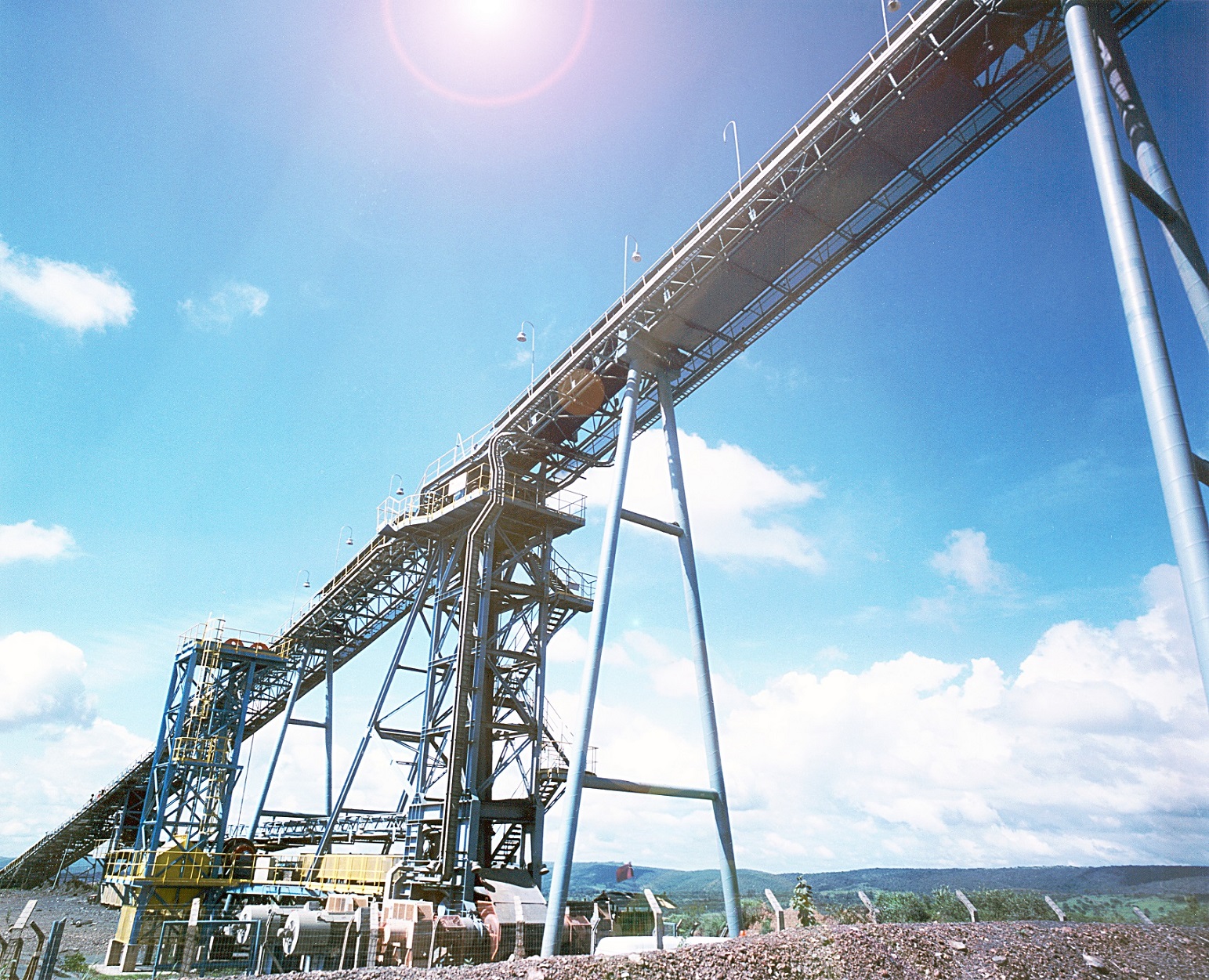

Lars Duemmel, vice president, Bulk Material Handling Systems at Metso Outotec, said: "In mining and minerals processing applications, conveying is one of the most efficient and safest ways to transport bulk material. It is often referred to as the backbone of the entire process. The robust design of our overland conveyors allows for capacities of up to 20,000 tonnes per hour including over 5km on a single flight for a seamless process. What is also important is that you can achieve power savings of up to 30% with the patented Energy Saving Idlers (ESI)."

Duemmel said that thanks to Metso Outotec's extensive process engineering capability and proven installations around the world, the company is able to support its customers with complete end-to-end conveyor solutions. He added: "This includes concept studies and definitions for all types of terrains and route types with horizontal and vertical curves. Our expertise also covers post-installation services and maintenance, including a full range of accessories, belts and components featured in the recently launched Conveyor Solutions Handbook."