Jeroen van Ginneken, director o_ -highway engine sales at Cummins, explains: “To complement our strong Stage V engine range we are o_ ering a new product to make our customers’ processes easier. For key applications such as crushers, screeners, drills, air compressors and concrete pumps we are providing a drop-in solution, with more than 70% of the content pre-approved for installation. This makes the integration process simpler, reducing the lead time for customers.”

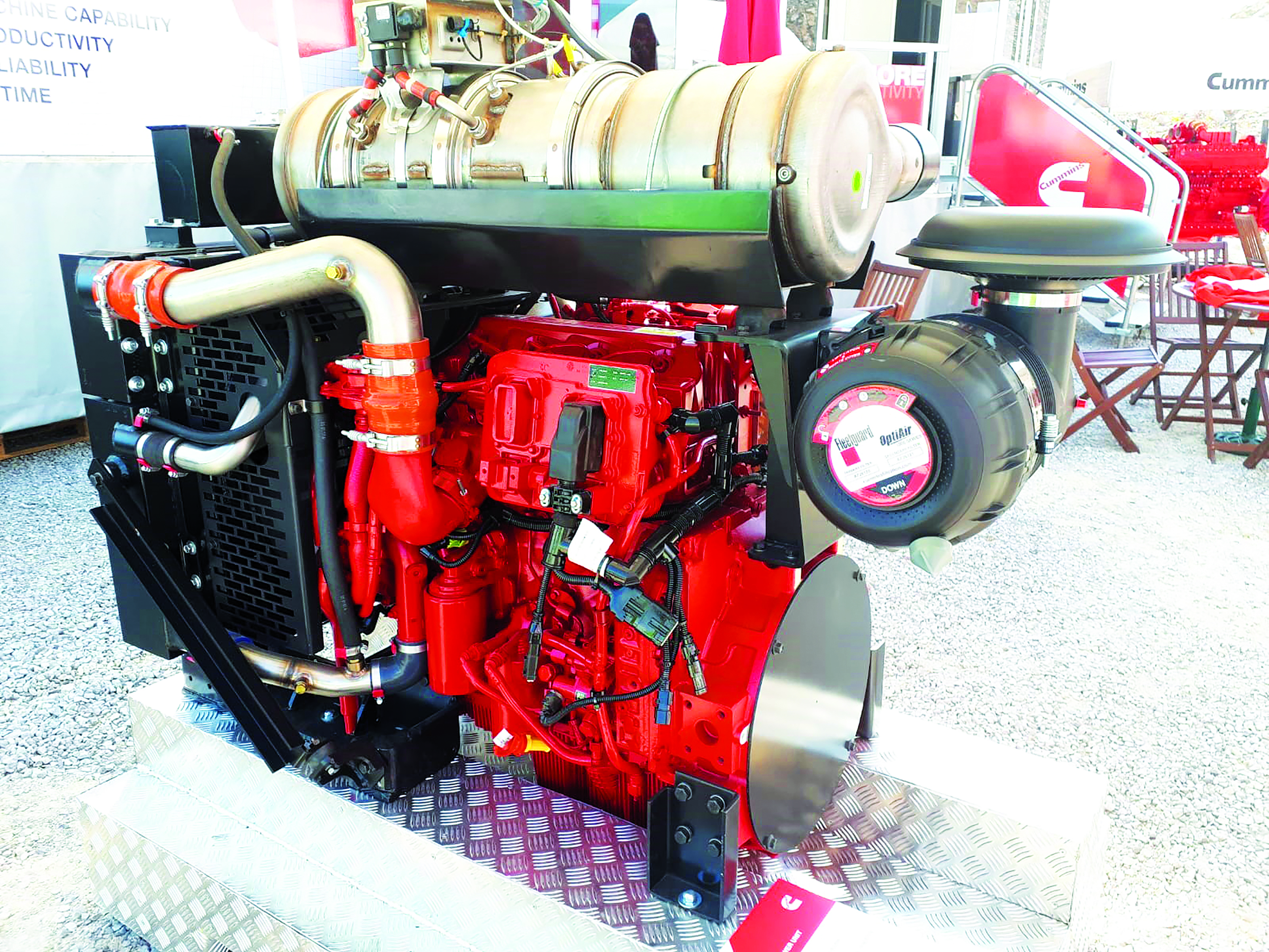

Cummins Stage V power units are available from 75–503kW. On display at Hillhead 2018 (booth CE2), the F3.8 power unit ranges from 75-129kW. The 3.8-litre engine has moved from 97kW at Stage IV to 129kW at stage V. Peak torque has increased by more than 20%, to 620Nm.

The F3.8 has an exhaust gas recirculation (EGR)-free design, supported by Cummins Single Module aftertreatment and its higher NOx conversion capability. It is lighter and smaller than the equivalent Stage IV aftertreatment; this means simpler architecture that is easier to install, with fewer parts and higher reliability.

The engine is more compact with lower weight, less to cool and lower engineering cost for manufacturers.

“Designed to increase machine capability, Cummins Stage V power units will drive construction, quarrying and agriculture machinery operating in even the most arduous duty cycles. They will deliver increased performance with less maintenance and service intervals of up to 1,000 hours,” added van Ginneken. The aftertreatment systems can be provided mounted or unmounted depending on customer requirements and each product is fully factory tested and supported by Cummins global warranty and service network.