A cross-industry UK initiative is aiming to develop technical solutions for future supplies of the cements used to stabilise radioactive waste.

The three-phase project - which involves the Nuclear Decommissioning Authority (NDA), Radioactive Waste Management, Sellafield Ltd, and research group Eden Nuclear and Environment - started in 2016 and is now in the final phase of implementing the recommended options. The project has identified that new approaches will be needed in future to address the growing risks from certain types of waste that require large volumes of cement.

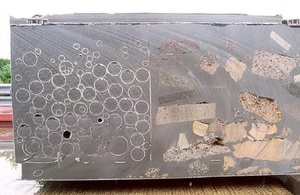

Cement is typically used to stabilise many kinds of radioactive wastes and the project is intended to ensure the continued availability of cement powders for encapsulation of UK higher activity radioactive wastes, prior to packaging, storage and eventual disposal.

Cement is an essential component of the grout mix that is used to stabilise/render more passive intermediate level wastes so they can be packaged for storage until a Geological Disposal Facility (GDF) becomes available.

The project partners say that this approach has been accepted practice for around 20 years, not just across the NDA estate but worldwide. A precise specification for the materials was developed to ensure consistency in setting time, fluidity and the avoidance of bleed water. The materials used, both now and in the future, also need to be accepted as suitable for disposal to the GDF.

The current cement mixtures rely heavily on sourcing by-products from two declining UK industries, pulverised fuel ash from coal-fired power stations and blast furnace slag from the steel industry.

The specifications are tightly defined and have remained largely unchanged since they were first devised.

Packaging/processing/grouting plants are typically designed to handle these very particular specifications, and to deal with a narrow range of waste streams.

Such issues pose questions about future availability, and the NDA initiated the three phase review to address these.

Phase 1 examined some of the fundamental issues around the continued use of cement. This phase took account of the industry’s commitment to minimal risk, inherent caution when dealing with radioactive waste and the high costs of investing in new plant. The conclusions established that the current approach is likely to suffice for sites needing to encapsulate waste in the short term, while the risks increase in future decades and particularly for those, for example, requiring large volumes of cement to deal with legacy wastes or to backfill emptied vaults/voids.

Phase 2 has identified potential solutions. Actions recommended include using the more flexible formula developed for Sellafield’s Box Encapsulation Plant which is based on more commercially available mixtures and wider sharing of assessments made by NDA’s subsidiary Radioactive Waste Management on the suitability of cement additives, such as superplasticisers, for disposal in a GDF. Greater collaboration among waste organisations to secure greater leverage with suppliers was also recommended.

A third phase has now been initiated and an industry co-ordination group established to take forward the recommended options. The group’s goal is to improve cross-industry working and develop technical solutions.