Ssanyong Cement wanted to use a HOTDISC reactor to substitute calciner fuel with alternative fuel (AF) at the two plants. However, the standard HOTDISC is designed for an ILC (inline) layout and did not fit within its existing SLC (separate line) calciner systems. A conversion to an ILC calciner to increase AF firing was not economically or technically feasible, so Ssanyong therefore asked Denmark-based FLSmidth to redesign the HOTDISC reactor to suit an SLC system.

Both Ssangyong Cement’s Donghae and Yeongwol plants operate older style non-FLSmidth pyro systems. Each plant has several kiln lines situated very close together. These were originally built without calciners, but SLC calciners have since been added as part of a preheater tower installed in front of the kiln.

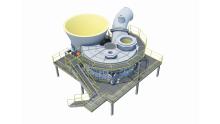

HOTDISC has been on the market for nearly 20 years, and FLSmidth says it has gained significant success as cement companies worldwide look to increase AF firing as an environmental and financial benefit to their process. It relies heavily on the positioning of the HOTDISC reactor alongside the bottom part of the ILC calciner, above the kiln riser. The challenge for FLSmidth's engineers working on the Ssanyong Cement installation was to produce a redesigned HOTDISC-S reactor that performs in the same way – maintaining those same efficiencies – but is positioned beneath the SLC calciner.

“It was a complex project. It’s not a totally new idea; we had thought of creating a version of the HOTDISC reactor for the SLC before – but the question was always ‘how do we get the non-combustible particles into the kiln?’,” said Steven Miller, global process line manager at FLSmidth. “Gases can be encouraged to move in one direction or another, but heavier materials only want to fall down. And at that temperature they are difficult to transport.”

Using CFD modelling, the FLSmidth design team was able to work out the optimum layout to ensure the lighter particles could be lifted into the calciner and successfully burned, and to avoid the occurrence of hot spots in the chamber. The answer to handling the heavy materials came from FLSmidth's experiences elsewhere in the process.

“We realised that the ABC Inlet design that is usually used in a clinker cooler would actually be the perfect way to cool those reject particles, so that they can be transported," said Miller. "It takes up a relatively small area, but it works very effectively to cool material quickly."

The HOTDISC systems operating at the two plants can handle a wide range of alternative fuels, including refuse derived fuel (produced from municipal garbage), tyres (whole, shredded or cut into pieces), paper sludge, lime-stabilised oil sludge (from tanker cleaning), old car fragments (including upholstery and dashboards), and dried sewage sludge.

The Ssangyong Cement plants are utilising Solid Recovered Fuel (SRF), which has been pre-sorted prior to receipt at the plant, ensuring they get good quality fuels with very low moisture content.

FLSmidth says the actual results of the installations have surpassed expectations. The guarantee of 85% waste fuel replacement in the calciner with SRF was exceeded at both Yeongwol and Donghae following commissioning in August 2020 and October 2020, respectively.

The Donghae Plant is claimed to be the world’s largest cement plant with an annual clinker production capacity of 11.5 million tonnes. Located on a 2,780-acre site, including the quarry, the plant has had the quality of its product accredited by many expert institutions both in and outside of the country.

"We had seen what the HOTDISC could do, in terms of increasing alternative fuel capacity," said Soo-Hyoung Lee, process engineer at Ssangyong Cement, PI Construction Office. "We were willing to support FLSmidth to redesign the system to try to make it work for us. They took on the challenge – and as a result we have been able to significantly increase our alternative fuels utilisation."