Weighing scales can increase aggregate efficiency, says Kevin Hill at Quality Scales Unlimited.

The most obvious advantage of using on site truck scales is the amount of data you have at your fingertips. Being able to scale your output and the various other aspects of your organization’s operations equips you with all you need to increase operational efficiency by making the operations cost effective.

Such data allows you to identify your key result areas while bringing to notice areas that can be enhanced in order to make optimal use of the resources available at hand. It also provides direction by serving as a base for future planning.

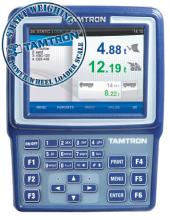

[caption id="attachment_84000" align="alignright" width="300"] The most obvious advantage of using on site truck scales is the amount of data you have at your fingertips[/caption]

The most obvious advantage of using on site truck scales is the amount of data you have at your fingertips[/caption]

And in spite of all the new information and innovations in the field of logistics, you might still be unaware of how unknown variables may be impacting your day-to-day operations. For a better understanding of the contribution truck scales can make, let us look at the various types of truck scales available and their uses, as follows:

Portable Truck Scales

Portable truck scales are manufactures with a high degree of accuracy and a low profile. They are designed to withstand several tons of weight and are protected from damage in case of overload.

Such scales are available in different capacities, configurations, specifications and lengths to be able to cater to various applications in the field of mining, construction, farming etc. These scales are also equipped with removable ramps, which prove helpful especially in adverse terrains. They are extremely easy to use because of their mobility and low profile.

Truck Axle Scale

These types of truck scales offer the highest degree if portability and cost efficiency. Truck axle scales offer a high degree of precision and are extremely durable in terms of their construction, making them perfect for operation sites with space constraints.

In-motion Portable Axis Scale

In-motion axis scales are a type of highly portable scales that have the ability to make quick measurements. These scales include a built in weight ticket printer and can also be integrated to on-the-fly tracking systems to reflect in your workflow, allowing you to stay updated on-the-go.

On-Board Truck Scale

On-board truck scales are used to ensure that the trucks aren’t overloaded, thereby avoiding on road fines and on-site loss that might accompany such a scenario. It can give you precise measurements allowing you to ensure the trucks are carrying the correct load for greater efficiency. This makes on-board trucks scales perfect for the mining industry considering the frequency of weighing their output as well as the scale of their operations.

Full Length Truck Scale

This scale set the standard for accuracy as the measurements are taken by positioning the truck on a large full length scale. These scales are generally preferred at sites that have a very high scale of operations and require accurate tracking on a daily basis.

Weighbridge Truck Scale

Weighbridge truck scales are similar to full length truck scales in terms of purpose, while also extending the advantage of offering more complex measurements. They are available in multiple sizes depending on the organizations requirements and can be customized as well. Such scales are widely used in industries that are required to regularly weigh trucks, or large amounts of materials of various configurations.

What's interesting to note is that truck scales prove to be an advantageous tool both onsite and off-site. It allows you to accurately measure the output, the optimal amount a truck can carry in a particular environment; all while ensuring you don’t have to worry about facing any on-road fines for overloaded vehicles or not meeting road regulations.

In summation, it is evident that truck scales are a cost effective option when it comes to efficiency in operations, however, its performance can also be impacted due to various factors, which also includes wear and tear. Therefore, it is necessary to regularly clean and inspect them as such protocols are vital to the scales accuracy. Apart from this regular calibration of the scale will increase its lifespan, thereby preventing losses due to inaccurate weight transactions and reduce costly repairs.

About the author

Kevin Hill is the content editor and online marketing manager at Quality Scales Unlimited. Always an early adopter and fast learner; Kevin combines his technical knowledge with content marketing in creative ways to give Quality Scales Unlimited a competitive edge.