Cement and mining equipment and linked technological solutions giant FLSmidth has a major presence in the Vietnamese building materials sector. Maxime Ramael, the Danish company’s country head for Vietnam, says the country of around 96 million people is one the fastest-growing cement producers in the world, thanks to robust domestic demand and its position as one the world’s top cement exporters. This success has brought challenges, however, and Ramael says the industry is now pushing to reduce its environmental impact, as well as optimising efficiency through the latest technology.

He continues: “Vietnam is continuing to grow its production capacity, and 7.1 million tonnes a year of capacity was expected to come online last year alone at [FLSmidth’s] Tan Thang (2.5 million tonnes a year) and Xuan Thanh 3 (4.6 million tonnes a year cement plant) – although that was before the outbreak of the COVID-19 pandemic. In total, installed [national] capacity is expected to reach 130 million tonnes a year by 2023.”

Ramael notes that much of this expansion is fuelled by demand for Vietnamese cement on the export market. “Of the 99 million tonnes of cement produced by the country in 2019, 34 million tonnes were exported, making the country one of the world’s leading cement exporters. China, the Philippines, and Bangladesh are the most significant buyers, although Vietnamese cement also made it as far afield as Peru.”

Vietnam’s position as an exporter owes much to its favourable geology, geography, demographics and climate, states Ramael. “With its long coastline and deep-water harbours, the country is within easy reach of the Indian Ocean and the markets of South Asia and Africa, as well as the neighbouring markets of southeast and east Asia,” he continues. “Meanwhile, its plentiful and easily-accessible supplies of limestone, coupled with a large labour pool, enable the low-cost production of high-quality cement, allowing Vietnamese cement companies to compete with local suppliers in countries like the Philippines, even with the addition of freight costs.”

He also notes that Vietnam’s climate – with its wet and dry seasons – supports its export business with cement companies turning to exports when the rains come and domestic construction activity slows.

“That is not to say Vietnam is without challenges, however. In common with the rest of the world, the Vietnamese cement industry has been hit by COVID-19, which has slowed demand for cement both domestically and in key export markets. In response, the government has announced stimulus packages worth about US$12.1 billion to help reduce the impact of the pandemic on the economy.”

Although cement demand was anticipated to pick up again through the second half of 2020, Ramael stresses that export markets may be more problematic. However, he notes that Vietnam’s strengths put it in good stead to take advantage when demand begins to recover.

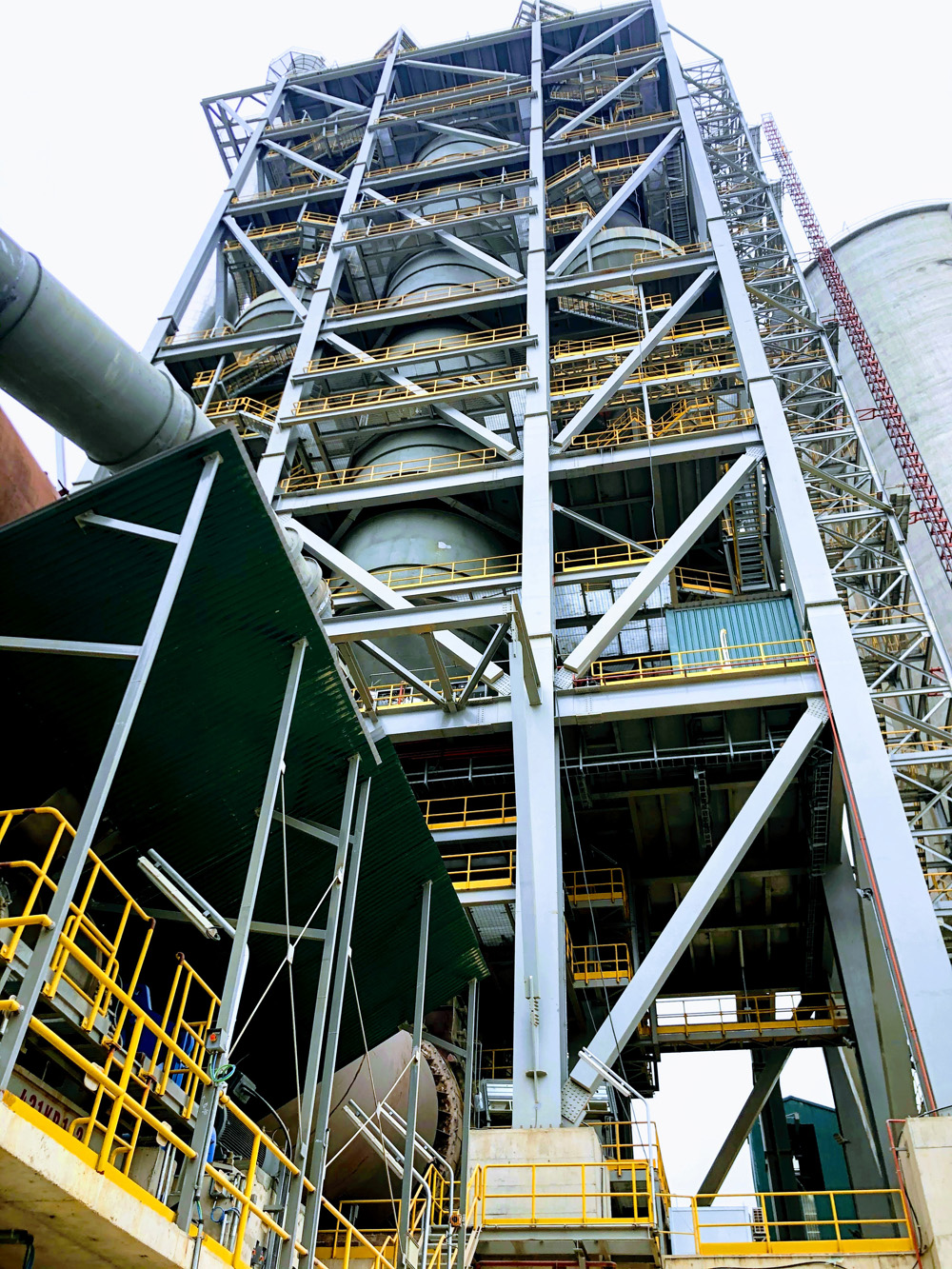

He adds: “COVID-19 has also posed challenges to the completion of CAPEX (capital expenditure) projects. Much of FLSmidth’s support of the new Tan Thang production line, which it supplied, is by necessity now being offered remotely, after the company had to repatriate workers home due to the pandemic. The plant has now started up and is producing clinker as it goes through performance-guarantee testing.

“Thanks to our solutions and the professionalism of the team, we are able to support our customer remotely through final commissioning and to obtain stable production.”

Beyond the immediate challenge posed by the current health crisis, the Vietnamese cement industry is facing more long-term environmental and sustainability challenges. Ramael says the country was ranked 15th by IQAir in its assessment of the most polluted countries in the world in 2019 with Hanoi, the capital city, often suffering from very poor air quality. Hanoi lies within easy reach of many of the country’s cement plants, underscoring the importance of improving the cement industry’s environmental footprint. To this end, the government has set objectives to improve efficiency and reduce the environmental impact of cement production.

“To support this objective, in February last year, FLSmidth and VICEM, the largest cement producer in Vietnam, announced a cooperation agreement to pioneer new solutions to improve the sustainability of the sector,” says Ramael. “The agreement will focus particularly on increasing use of alternative fuels from municipal and other waste streams, such as biomass from the country’s rice and forestry industries.”

He says the cooperation agreement is the latest development in a long history of FLSmidth support for the Vietnamese cement industry. He adds: “The company supplied Vietnam’s first cement plant, Hai Phong Cement, 120 years ago. It remains a major supplier to the industry, including the 5000 tonnes per day line at Tan Thang and a 12,500 tonnes per day production line at Xuan Thanh Cement, one of the largest in the world, with another similarly-sized line on the way.”

The construction industry in Vietnam is the best performing in the Asia-Pacific (APAC) region. Prior to the COVID-19 outbreak, the Vietnamese construction industry had recorded an average annual growth rate of 9.6% in the five years to 2019. However, construction activities were disrupted due to the stringent measures taken by the government to contain the spread of the virus.

Dhananjay Sharma, construction analyst at GlobalData, says: “Efforts to attract foreign investments through the public-private partnerships (PPP) model will support the construction industry during 2020-2024. In June 2020, the national assembly adopted a law on PPP investment, which is aimed at regulating investment activities and attracting private investment under the PPP model.

“Vietnam plans to speed up spending on infrastructure projects to help support the overall construction output growth, with focus on improving regional connectivity through the development of the country’s rail, road and air transport infrastructure, coupled with efforts to boost energy production.”

A new report from Mordor Intelligence (Mordor) titled Infrastructure Sector in Vietnam - Growth, Trends, and Forecast (2020 - 2025) highlights that a series of new transport infrastructure projects are getting underway in Vietnam’s Ho Chi Minh City, creating significant demand for aggregates, concrete, cement, and other building materials.

In all, 13 key traffic projects are being carried out, having been planned by the Ho Chi Minh City (HCMC) management board for traffic projects. The works are worth a combined US$150 million. As one of the fastest-growing economies in ASEAN (The Association of Southeast Asian Nations), Vietnam has a seemingly endless wish list for infrastructure. In 2019, just 20% of the country’s national roads were paved, and a recently approved plan to build a 1,372km north-south highway by 2030 is estimated to cost $14bn.

The Mordor study notes that the rising population in Vietnam’s major cities in recent years has strained and exceeded the capacity of the existing connectivity networks and utility systems. With 50% of Vietnam’s population expected to be living in cities within the not too distant future, Hanoi and Ho Chi Minh City are building rapid transit systems exceeding US$22 billion in the hope of reducing private vehicle ownership and improving air quality.

Home to 107 million people, the Philippines is one of the most dynamic economies in the East Asia Pacific region. With increasing urbanisation, a growing middle class, and a large and young population, the World Bank notes that the Philippines’ economic dynamism is rooted in strong consumer demand supported by a vibrant labour market and robust remittances. Business activities are buoyant with notable performance in the services sector including the business process outsourcing, real estate, and finance and insurance industries.

Sound economic fundamentals and a globally recognised competitive workforce reinforce the growth momentum. Having sustained average annual growth of 6.4% between 2010-2019 from an average of 4.5% between 2000-2009, the country is on its way from a lower middle-income country with a gross national income per capita of US$3,850 in 2019 to an upper middle-income country (per capita income range of US$4,046–$12,535) in the near term.

However, the World Bank notes that real economic growth has been challenged by the COVID-19 outbreak and the strict community quarantine measures imposed in the country. Growth was projected to contract in 2020, driven by significant declines in consumption and investment growth, and exacerbated by the sharp slowdown in exports, tourism, and remittances.

Nevertheless, economic growth is expected to rebound gradually in 2021-2022 assuming a containment of the virus domestically and globally, and with more robust domestic activity bolstered by greater consumer and business confidence and the public-investment momentum.

The Philippines construction industry, which was the fastest-growing in the Asia-Pacific (APAC) region prior to the COVID-19 outbreak, has been devastated by COVID-19 and is expected to post a sharp contraction of 9.2% in 2020, reports GlobalData. However, the industry is expected to bounce back strongly in 2021 and grow at an annual average rate of 8.3% during 2021-2024. Consequently, the industry’s output value (measured at constant 2017 US dollar exchange rates) is expected by GlobalData to reach US$75.1bn in 2024.

In the short term, the industry is expected to be affected by the disruptions caused to the construction activities due to the containment measures. The effect of COVID-19-lockdown restrictions and the disruptions in the Philippines construction industry are evident in the latest value-add data, which recorded a year-on-year contraction of 33.5% in the second quarter of 2020, according to the data released by the Philippine Statistics Authority.

Global Data’s Dhananjay Sharma says: “Apart from the complete halt in the construction activities in the second quarter [2020], the output will also be affected [in 2020] by the re-allocation of government resources to address the current crisis. In June 2020, the Department of Budget and Management (DBM) reduced the infrastructure spending target for 2020 by 15.8%, from PHP989bn to PHP833bn due to funding re-alignment to tackle the pandemic.”

Construction work resumed in mid-May 2020 with the government expecting the resumption of infrastructure projects to be a key driver in reviving the economy. Prior to the outbreak, the government had planned to invest around PHP1 trillion (US$18.9bn) on the Build, Build, Build (BBB) programme in 2020, and the implementation of the programme will play a major role in the post-pandemic recovery of the country’s economy.

Holcim Philippines has partnered with UN-HABITAT to build homes for families displaced by conflict in the city of Marawi. The company has also provided funding to train and certify masons and carpenters with the Philippines’ Technical Education and Skills Development Authority.

Up to December 2020, 116 apprentices had graduated, and more than 200 houses have been built using close to 40,000 bags of Holcim Philippines cement.

Holcim Philippines senior vice president for sales, William Sumalinog, says the company is ready to provide reliable cement supply for the rehabilitation of Marawi and the construction activity in Mindanao.

“We are happy to know about the steady progress of Marawi. Being from a neighbouring province, our plant in Lugait, Misamis Oriental is well-positioned to support the city’s reconstruction with a reliable supply of high-quality cement. We are also ready to support all our partners in Mindanao as they implement construction projects that will help us recover from this year’s challenges and be more resilient moving forward.”

CEMEX Philippines is investing approximately US$235 million in a new cement line, which recently reached a milestone with the lifting of the new rotary kiln into position.

The new cement line at CEMEX Philippines’ Solid Cement plant in Antipolo city will add 1.5 million tons of cement to its annual capacity, increasing its output to 3.4 million tons.

“This milestone demonstrates our full commitment to the development of the country and brings us closer to further strengthening our position in providing the infrastructure and building needs for economic development,” said Ignacio Mijares, CEMEX Holdings Philippines CEO and president.

Tong Laigou, chairman and general manager of CBMI Construction (CBMI), the company contracted by CEMEX to build the new cement line, applauded the lifting of this new rotary kiln in the record time of two days. In a communication shared with CEMEX, he said that the CBMI and CEMEX Philippines’ teams worked under strict protocols to secure site safety and have also made great efforts to achieve this milestone.

The Solid Cement plant’s new cement line boasts of environment-friendly features that include the use of less energy as it is designed to reuse waste hot gases for drying raw materials, as well as the use of high-efficiency bag-filter technology to significantly improve dust-emission control far below the actual regulation. Furthermore, CEMEX is prioritising sustainable operations through its proprietary ‘Low-Temperature Clinker’ technology that will reduce carbon dioxide emissions.

With aggregates demand of around 200 million tonnes a year, Thailand is a major player in the Southeast Asian aggregates sector. And Thai government plans to deliver public-private partnership (PPP) projects worth 1.09 trillion baht (US$33.39 billion) in the 2020-2027 period will have caught the attention of building material producers not just in the region, but globally. Such investment is an eye-catching part of prime minister Prayut Chan-o-cha’s plans to revive Thailand’s struggling economy amid the coronavirus pandemic, which has hit the country’s tourist sector particularly hard. Reuters news agency reports Prapas Kong-Ied, head of the State Enterprise Policy Office, saying that the 92-project plan includes 18 high-priority infrastructure projects worth 472 billion baht.

A country of 70 million people, the World Bank notes that the last four decades have seen Thailand make remarkable progress in social and economic development, moving from a low-income to an upper-income country in less than a generation. As such, Thailand has been a widely cited development success story, with sustained strong growth and impressive poverty reduction.

While Thailand has been successful in stemming the tide of COVID-19 infections over the last few months, the World Bank reports that the economic impact has been severe and has led already to widespread job losses, affecting middle-class households and the poor alike and threatening hard-won gains in poverty reduction.

Economic growth in Thailand was expected to contract in 2020, being among the sharpest projected declines in the East Asia and Pacific region due to a decline in external demand affecting trade and tourism, supply chain disruptions and weakening domestic consumption.

Global Data’s October 2020-published report Construction in Thailand – Key Trends and Opportunities to 2024 states that Thailand’s construction industry has also been affected by the disruption caused by the coronavirus pandemic. Although Thailand imposed a strict lockdown until May 2020, construction activities held up relatively well, as most of the construction work progressed without much disruption. However, the GlobalData study notes that certain projects are expected to face delays and subsequent cost overruns, as the pandemic has caused supply chain disruptions, and led to a shortage of labour in the construction industry.

During the remaining part of the forecast period, Thailand’s construction industry is expected to register an average annual growth of 3.7% between 2021-2024, supported by improving investor and consumer confidence, and government investments in road, rail, renewable energy and housing projects.

GlobalData notes that the Thai government’s pre-COVID-19 plans to develop transport infrastructure are also expected to drive the industry’s growth over the forecast period. Under the Southern Economic Corridor (SEC) project, the government plans to invest THB106.8 billion (US$3.4 billion) in the development of 116 projects during the period of 2019-2022.

Under the Eastern Economic Corridor (EEC) scheme, the government approved four more large-scale infrastructure projects; as a result, the total number of projects approved under the EEC scheme reached five, with a combined value of THB652.5 billion (US$20.2 billion); these projects are expected to be completed by 2023.

HeidelbergCement is well placed to cater for the wide-ranging infrastructure works planned in the country over the next couple of years. The Germany-headquartered multinational building materials maker has been present in Thailand since the second half of 2016, when it purchased the Italcementi Group. Italcementi has a shareholding in Jalaprathan Cement (JCC), which was established in 1956 by the Royal Irrigation Department for the construction of Bhumibol dam, the first multipurpose concrete dam in Thailand. JCC has its plants in Takli and Cha-am.

In 1999, the group increased its presence in Thailand becoming a shareholder of Asia Cement (ACC). ACC was founded in 1989 and operates a cement plant in Pukrang. In line with the group’s energy strategy, in June 2013 Asia Cement commissioned a waste heat recovery and power generation plant (WHR&PG Plant), based on steam, of 21MW gross power capacity in the Pukrang plant. This will help reduce energy costs in accordance with the principles of renewable energy while also minimising the use of fossil fuels, a way to develop clean energy that can effectively help in reducing greenhouse emissions. In numbers, this 21MW power plant can produce 150 million kWh per year without using fossil fuels implying a carbon dioxide production decrease of 120,000 tonnes per year.

Meanwhile, Terex Washing Systems (TWS) recently made the first sale of an AggreSand 165 wash plant in Thailand. Manufactured at TWS HQ in Dungannon, Northern Ireland, the plant will be operated by one of Thailand’s largest construction companies, Chiangmai Construction, based in the north of the country.

The company processes three feed materials: one-inch rock, crusher dust and waste rock, and with the introduction of the AggreSand 165 modular wash plant, Chiangmai Construction can produce two aggregates and two manufactured sands (0-3.5mm and 0-5.5mm) to meet the C33 spec.

Chiangmai Construction is also dedicated to conserving water which can be achieved by the AggreSand 165 washing solution due to its efficient water management.