The cement and construction industries are among the highest CO2 emissions generators in the world. The cement industry alone accounts for 8% of global emissions, not far behind the agriculture industry with 12%. Given that context, it is not surprising on our Teams call that Dr Edelio Bermejo is keen to articulate the importance of discovering and utilising greener building materials if the cement and concrete industry is to achieve its ambitious goal of net-zero concrete by 2050.

“When you look at global population growth, there will be around 2.5 billion more people on our planet by 2050, 80% of which will be living in urban areas that will be built up vertically and horizontally. Two-thirds of the infrastructure required by 2050 is not yet built. Concrete will be in high demand, and as we emit CO2, we have no choice but to decarbonise it and go for net zero. We need to rethink how we design every building or other structure and reduce the amount of material going into it without reducing its final quality. It is also important not to lose sight of the present. Today, the equivalent of a New York City is built every month!”

Bermejo stresses that as the global cement and concrete industry gets nearer its 2050 net-zero goal, it will need a lot of financial assistance from governments and other bodies, such as the World Bank and the IMF (International Monetary Fund), to build and maintain the required infrastructure to store and utilise the captured CO2.

When asked about the role of China, by far the biggest producer of concrete and cement, within the global industry’s efforts to decarbonise by 2050, Bermejo responds: “When China decides there is no other way to produce concrete and cement without decarbonising it, they will do it. In 2008, they decided there were too many cement players – around 2,000. They were emitting a lot of carbon. The Chinese government then said, ‘In four years, I only want 200 companies left operating. The rest will be closed’.

“What happened was that the very old plants were closed, and then the larger players bought the smaller ones and invested in new, greener production technologies. As a result, they have made a huge improvement in reducing their CO2 emissions.”

Aggregates Business recently reported on Holcim’s launch of the world’s first 1.5°C science-based framework to decarbonise the cement industry, resulting from its partnership with the Science Based Targets initiative (SBTi). This 2030 targeting framework was independently developed by the SBTi, in collaboration with an expert advisory group representing academia, civil society and industry to decarbonise cement in a rigorous and science-driven way. The Net-Zero Standard offers companies robust certification to demonstrate to consumers, investors and regulators that their net-zero targets are reducing emissions at the pace and scale required to keep global warming to 1.5°C.

The recent launch of Holcim’s SBTi-validated landmark framework could not have been better timed for Bermejo, a Spanish-French dual national, given his key speaker engagement at CarbonZero: Alternative Fuels and Raw Materials 2022 on November 10 and 11. Featuring a conference and exhibition, the event was held at the Pestana Palace Hotel & National Monument in Lisbon, Portugal, focusing on topics that make the agenda of the biggest cement and construction companies worldwide.

Highlighting the overall theme of the conference, Breaking old habits and patterns, Bermejo, who is based at Holcim’s state-of-the-art R&D headquarters in Lyon, France, talked about Holcim’s strategy for decarbonising the cement industry. Holcim dedicates more than 80% of its innovation resources to developing sustainable products and solutions. The group’s 2020-launched ECOPact range of green concrete is proving popular worldwide, and its recently launched ECOPlanet range of green cement is said to deliver at least a 30% lower carbon footprint with equal-to-superior performance. Holcim plans to produce 100 million tonnes of recycled materials by 2030 and utilise technologies like 3D printing that use 70% fewer materials without compromising performance. The group has further across value chain net zero by 2050 targets.

“I am very honoured to speak at this conference and to show that Holcim is the world leader in this area. It is a fantastic opportunity to focus on two key decarbonisation topics – alternative fuels and alternative raw materials. You need to focus on them simultaneously and in the presence of senior representatives from large as well as smaller- to medium-sized industry companies,” says Bermejo. “The entire industry needs to move on this.”

Holding a PhD in Materials Science, Bermejo has 27 years of experience in product development, marketing, and operations in the cement industry. As Holcim’s global head of R&D & IP, a role he has been in for the past three-and-a-half years, his primary responsibility is accelerating the time to market of existing R&D projects and fostering a more visible innovation culture and external partnerships around new ideas and business models, such as the decarbonisation of the construction industry.

“The industry’s decarbonisation started decades ago and involved all key players. This has meant using alternative fuels, reducing the clinker factor, and leveraging the use of cementitious materials, including slag, pozzolana, and fly ash, across all geographies. What has not been developed enough is the use of alternative [building] materials. Our net 2021 CO2 emissions were 553kg of CO2 per tonne of cementitious material. We are on track to meet our 2030 target of 475kg of CO2 per tonne of cementitious material. We insisted on having interim targets. Otherwise, you are at risk of saying, ‘Guys, just trust us, and by 2050 you will get zero-emission cement’.

“As important as decarbonising our industry is making it circular, with very clear goals. From Holcim’s perspective, it means moving from 54 million tonnes of recycled materials used [in cement production] in 2021 to 100 million tonnes by 2030.”

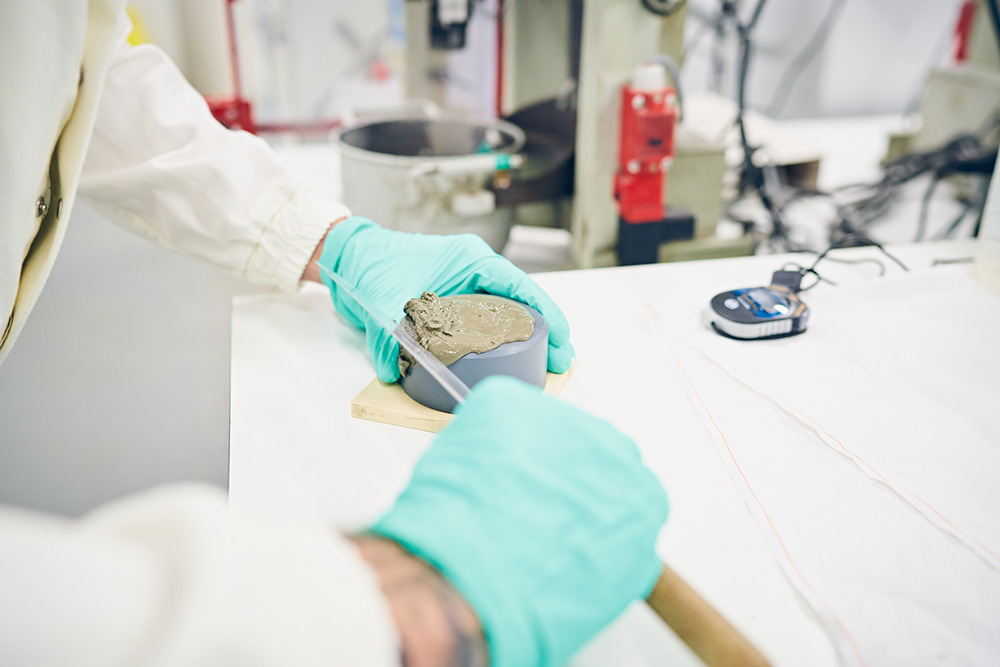

Bermejo says Holcim’s 15,000m² Lyon R&D facility includes 210 fixed-post researchers, plus some internships, who are supported by a network of R&D colleagues based in Switzerland, Austria, China, and Mexico. “We have a centralised R&D operation, but when it comes to research ideas, it’s very decentralised,” he explains. “I cannot invent the concrete needed in Manila to fight against flooding if I’m not in Manila. Local customisation is essential. We have more than 40 PhD holders working across continents on fundamental research.

“Eighty per cent of our R&D work is related to sustainability. We also work on product digitalisation and market differential. We have more than 1,800 product patents – and more than two-thirds are related to sustainability. I am very proud of our open Innovation platform through which we have strong partnerships with more than 120 start-ups, either through a financial or equity stake or via an MoU [Memorandum of Understanding].”

I am keen to discuss Holcim’s recent investment in COBOD International, a global leader in 3D construction printing, to advance world-class 3D printing materials, robotics and automation. Building on its collaboration with COBOD since 2019, Holcim aims to grow its innovative range of proprietary ink, TectorPrint, tailored for 3D printing. Holcim and COBOD have collaborated on various novel building projects, from 3D-printed windmill tower bases with GE to the world’s first 3D-printed school in Malawi and Africa’s largest 3D-printed affordable housing project in Kenya.

Holcim’s TectorPrint is an innovative 3D printing ink range that can be tailored for complex applications from residential buildings to infrastructure. Empowering smart design, 3D printing can reduce material use by up to 50% to build better with less, with no compromise in performance.

“The reason why we are moving into 3D printing is because automation is crucial to the future of the construction industry. If you look at productivity in construction for the last 70 years, it has been almost flat or very slow growth. We really need to increase automation in construction, and one of the mass-market solutions is 3D printing. With this technology, we are building houses in Africa and headquarters in Europe. In 2023, we are also going to be using 3D printing to build concrete windmills for General Electric in North America.

“There is also a sustainability benefit when we are building with 3D concrete printing, as we are just printing the amount of concrete needed. Last year at the Venice Biennale, we presented the Striatus arch bridge that we and partners built entirely with 3D concrete printing.”

COBOD International is also partnering with CEMEX and other major global building materials players, a development that Bermejo welcomes.

“I was more than happy to see CEMEX moving into this area. My view is, ‘Please, join us’. The more of us moving in this direction, the better chance we have of raising building standards by convincing politicians of the need for this approach.”

Another eye-catching area of research Holcim is involved in is the concrete inductive charging of electric vehicles. “This is using concrete roads and pavements to charge electric vehicles that are moving. The work in this area started with scooters. The IBIS hotel in Munich has scooters that charge when travelling over our concrete routes. We will then look at charging forklifts working in warehouses, buses and, finally, cars travelling on concrete roads. We don’t want to create over-expectation in this area. This is not widescale technology for tomorrow. It is research.”

Bermejo says the progressive approach to recycled building materials adopted by national and local government in Holcim’s native Switzerland enabled the group to develop, three years ago, the world’s first cement including 20% recycled construction and demolition (C&D) waste material. “That means 20% less primary resources drawn from nature. Since then, we have been looking to push building codes and create incentives to have more than 20% C&D waste in cement, not just in Switzerland but across Europe. Now, a new EU cement law being introduced in a few months will allow up to 35% of C&D waste to be used in cement for construction works. This is great circular construction progress made via the standardisation bodies.”

The ongoing development of low-carbon concrete solutions will need to answer a key question, as Bermejo explains: “Today, we have very much been producing lower carbon concrete with slag, but the lack of availability of slag, largely through steel production sites closing, is pushing its price through the roof. Fly ash is also disappearing globally. So, the key question is, ‘How can I develop a low-carbon concrete without slag and fly ash?’”

Bermejo says he and Holcim colleagues work very closely with other major and small- to medium-sized building materials companies via the London, England-headquartered Global Cement & Concrete Association (GCCA). Representing 80% of the world’s concrete industry outside China, the association’s mission is to position concrete to meet the world’s needs for a material that can build and support growing modern, sustainable and resilient communities.

In 2021, the GCCA launched its 2050 Cement and Concrete Industry Roadmap for Net Zero Concrete, setting out its member companies’ collective commitment to ensuring that the cement and concrete industry will play a major role in building the sustainable world of tomorrow.

“We are involved in the association’s common scientific network through which all company members can benefit from accessing the latest industry technologies, like CCUS (carbon capture, utilisation & storage). At the same time, I’m leading the GCCA Open Innovation Challenge involving the best start-ups whose ideas and solutions could benefit the entire industry by solving the issue of cement and concrete decarbonisation.”

Returning to the topic of rethinking the approach to the design of all new global infrastructure, Bermejo says: “We need to be thinking, ‘How can I make this fully recyclable and completely in line with the circular economy?’. For example, we ran a building project earlier this year where we created 100% recycled clinker to create 100% recycled cement. By the end of this year, we will start another building project involving 100% recycled concrete. We cannot do this every day, but it can act as the lighthouse for the journey to show just what can be achieved by all of us.”

Asked how he sees the global building products industry in a decade, Bermejo responds: “It will be improving in its lower CO2 footprint, and very much about environmental transparency, with EPDs (environmental product declarations). There will be much more embracing of the circular economy and a lot more use of digital solutions, including the use of sensors in concrete to collect a lot of data that can be used effectively via artificial intelligence.”

I end our conversation by asking what Bermejo enjoys most and least about his crucial work. “I like to find new ideas myself. When a new idea is coming, there is nothing better. I also like to encourage others to invent. My biggest frustration is the lack of speed in executing our plans. I know Holcim is a global leader in sustainable building product solutions, but for me, we are sometimes too shy and don’t want to be seen as arrogant. When I look at what Amazon and Google are doing, I would like us to be as arrogant as them! I always say to my teams, ‘Go, go, go and be part of the solution’.”